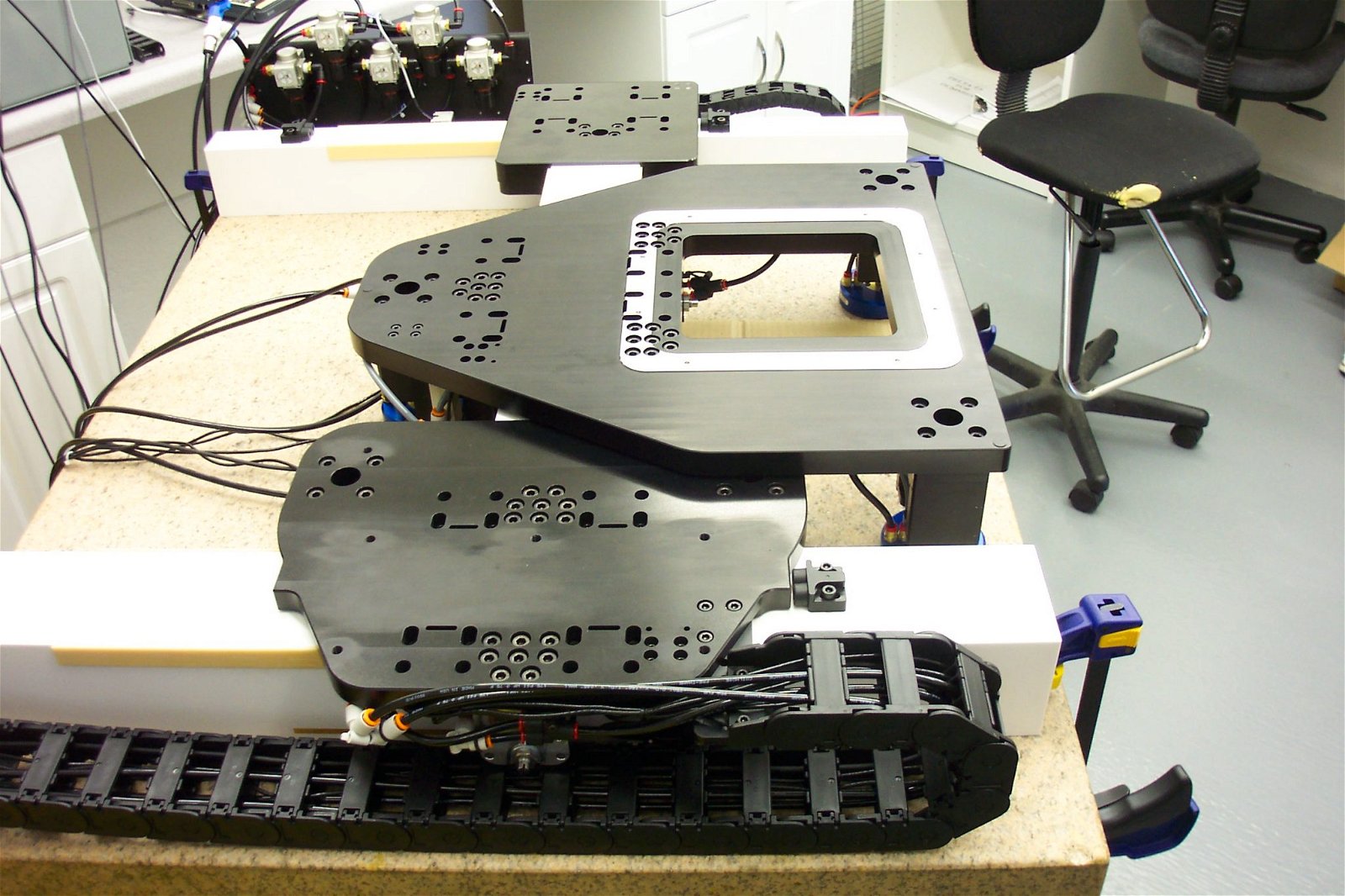

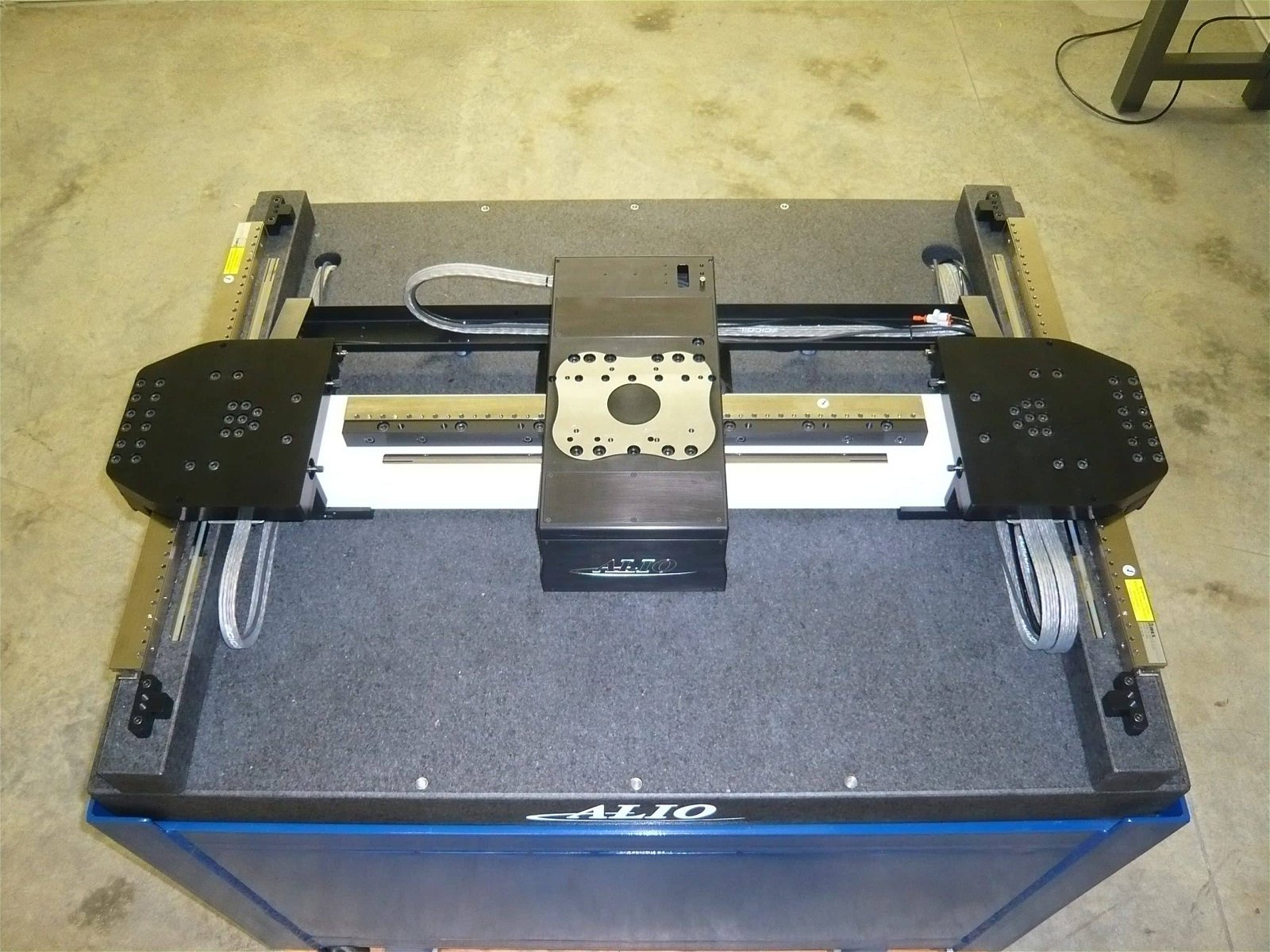

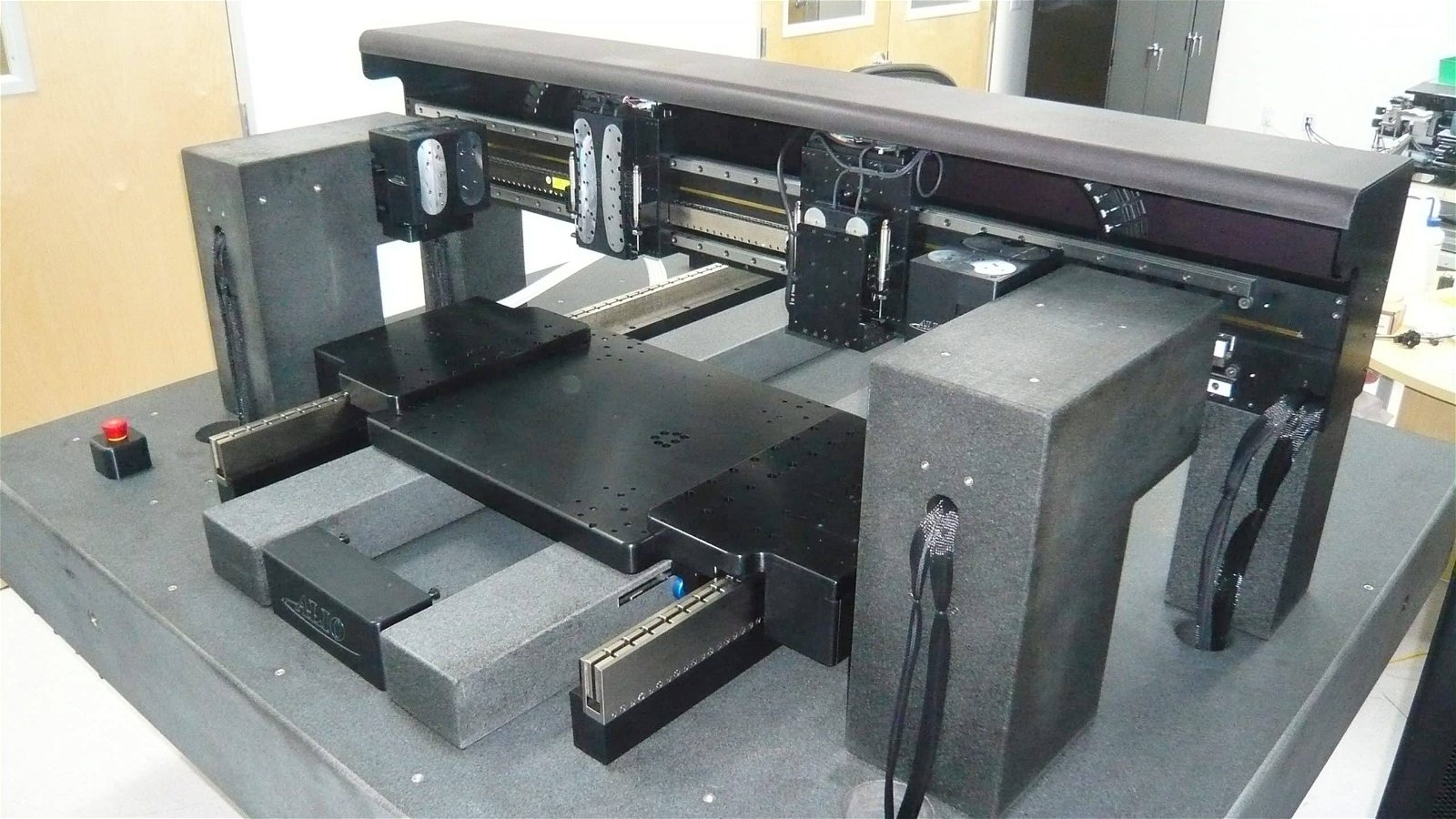

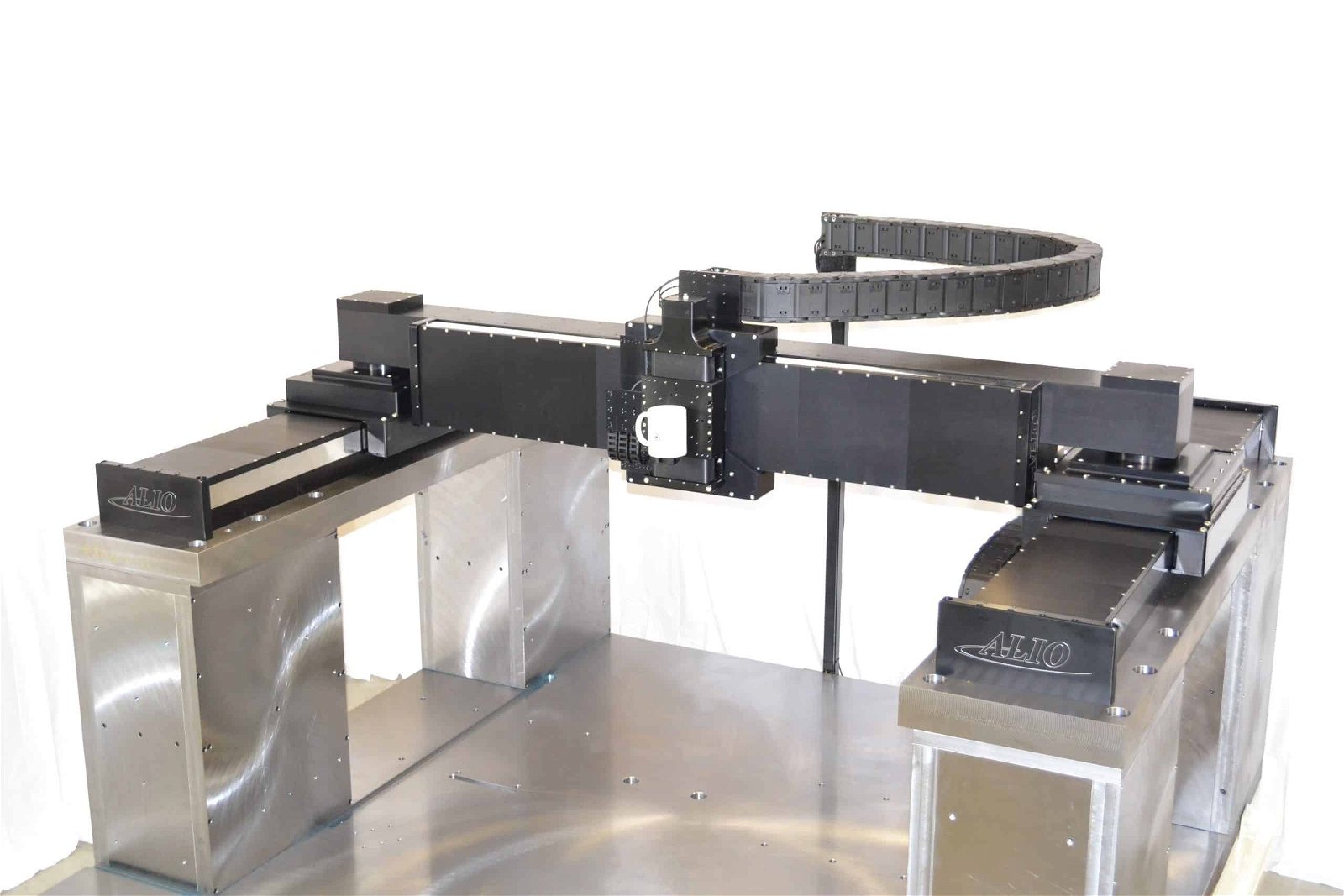

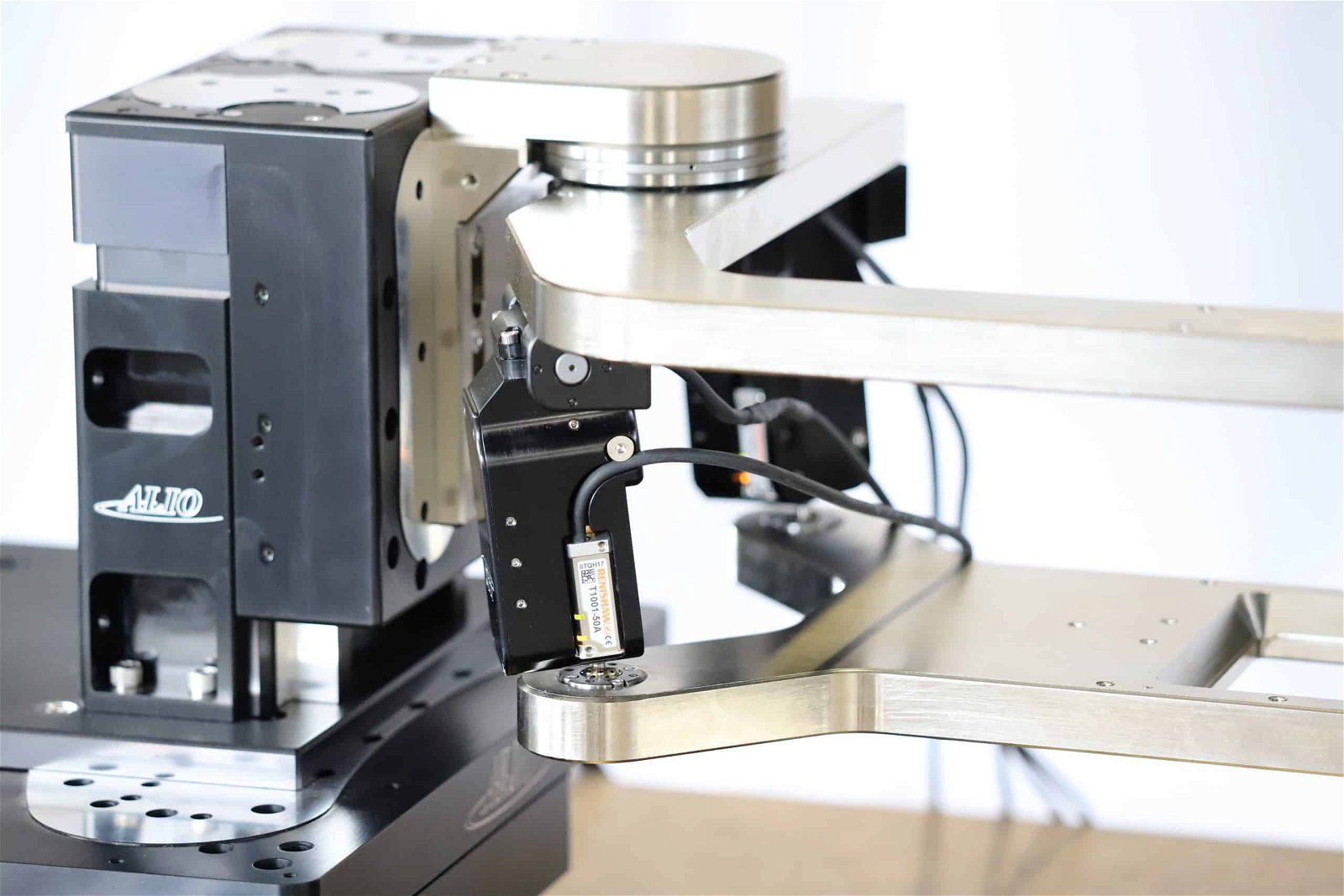

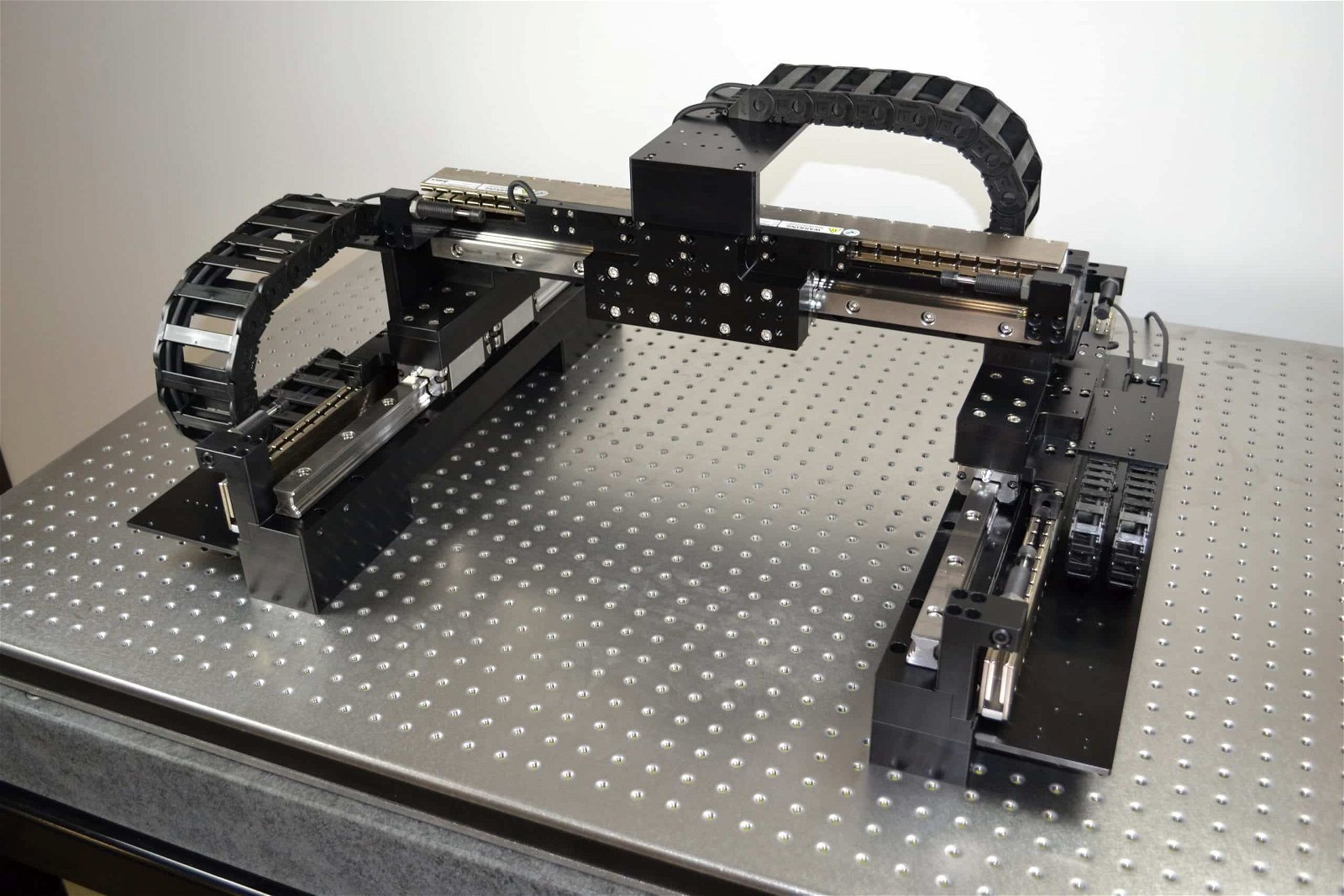

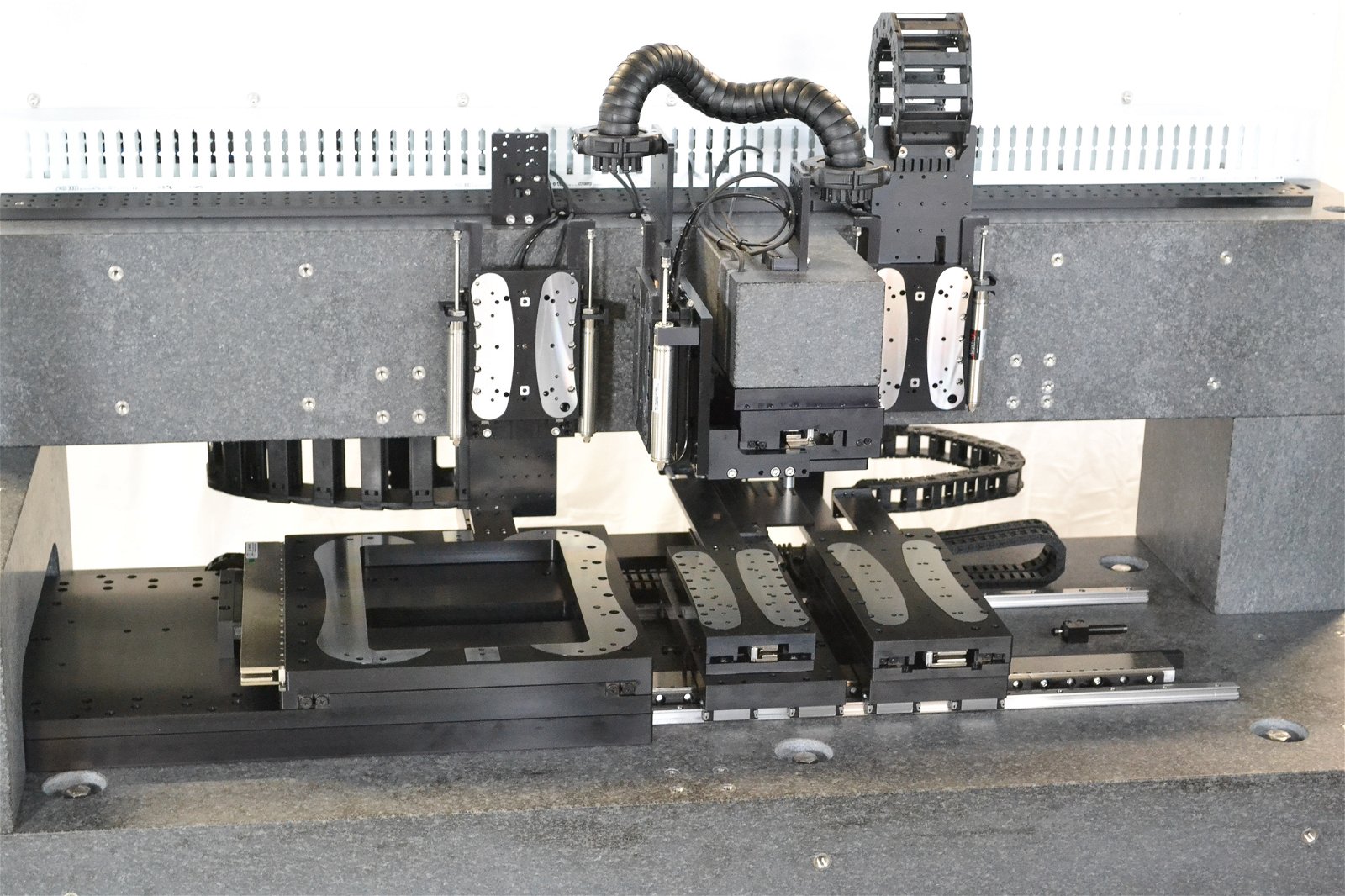

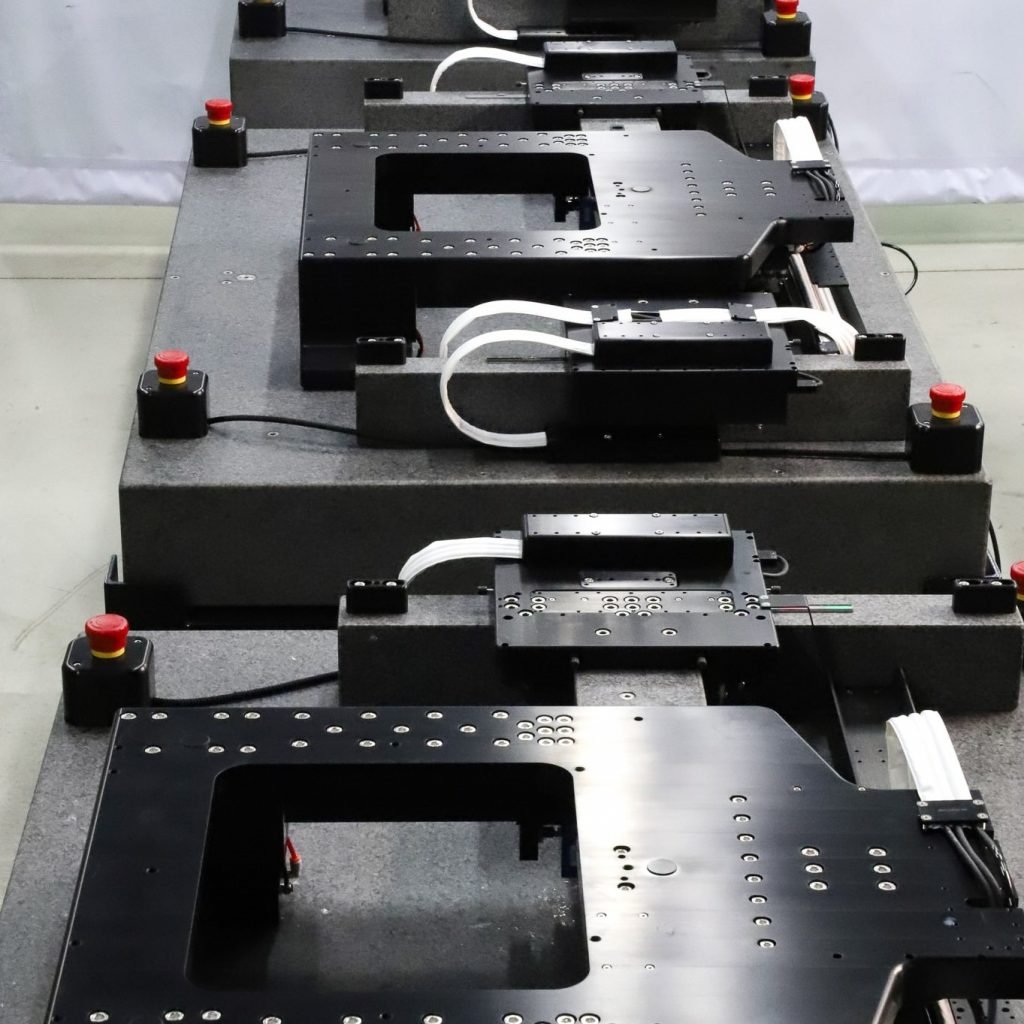

The SNH-series is a highly configurable gantry robot design based on ALIO’s proven standard stages that can be adapted according to customers’ load, throughput, precision, travel, and budget.

Customers may choose from XY travels from as little as 100mm or up to 1m plus and various powerful drive options allowing accelerations of up to 3.5G. With gantries being delivered on rigid base plates like granite, steel or aluminum frames allow superior precision with accuracy of +/- 1.5µm.

One key contributor to such high precision is our “Yaw Compliance” option — a virtual rotary axis allowing precise compensation for small angular misalignments that also may be used as an actual rotary axis for small intended angular motions.

Combining the gantry with optional degrees of freedom like z-axis, rotary axis, (Inverted) tripods or Hybrid Hexapods® or Gimbals makes this series to one of the most versatile and flexible high precision motion systems in the market.

You’ll likely find our gantries in industrial applications like laser machining or additive manufacturing / 3D printing, where an overhead motion is needed as samples can’t be moved or are extremely large.

An overview of “standard” configurations will show specifications:

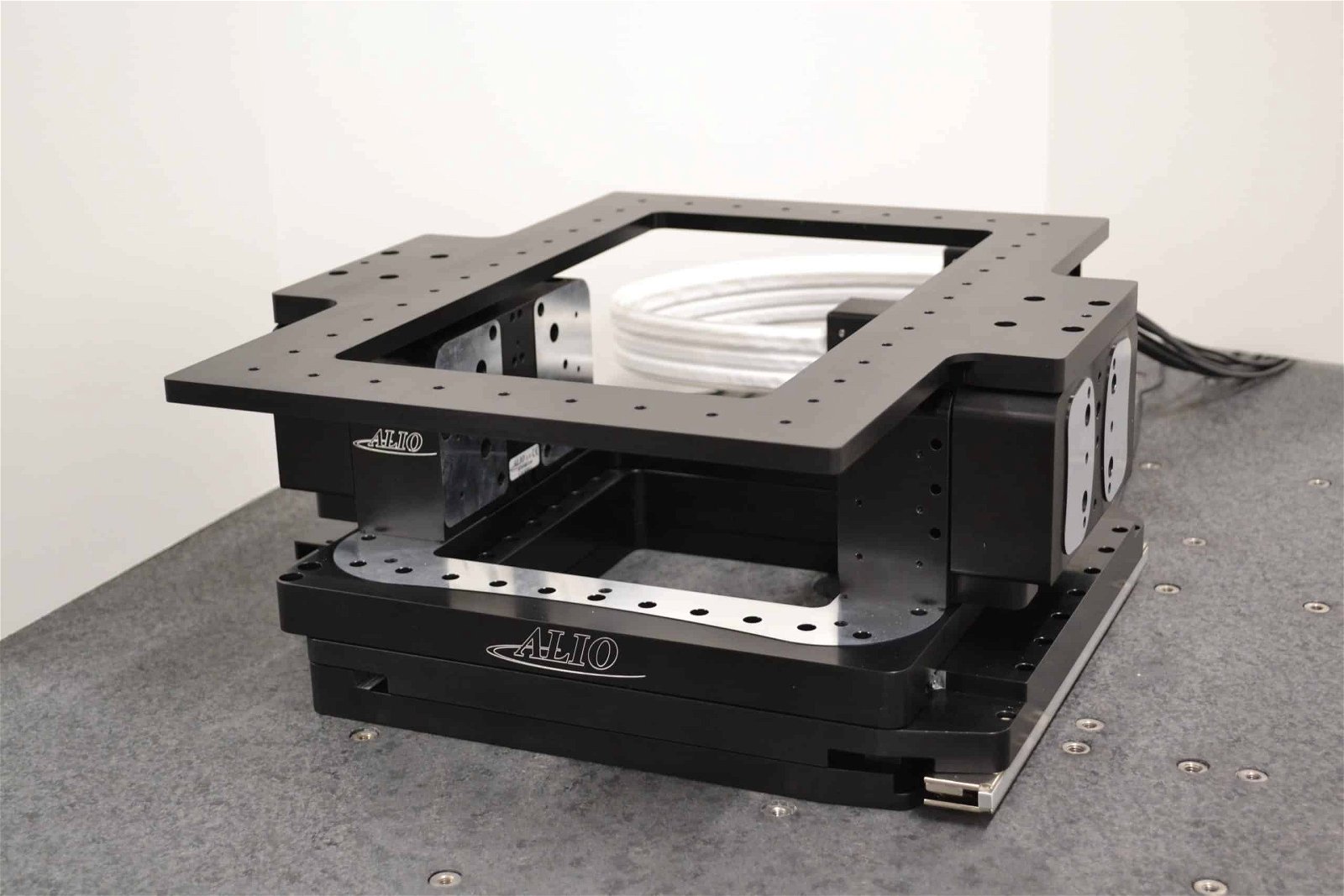

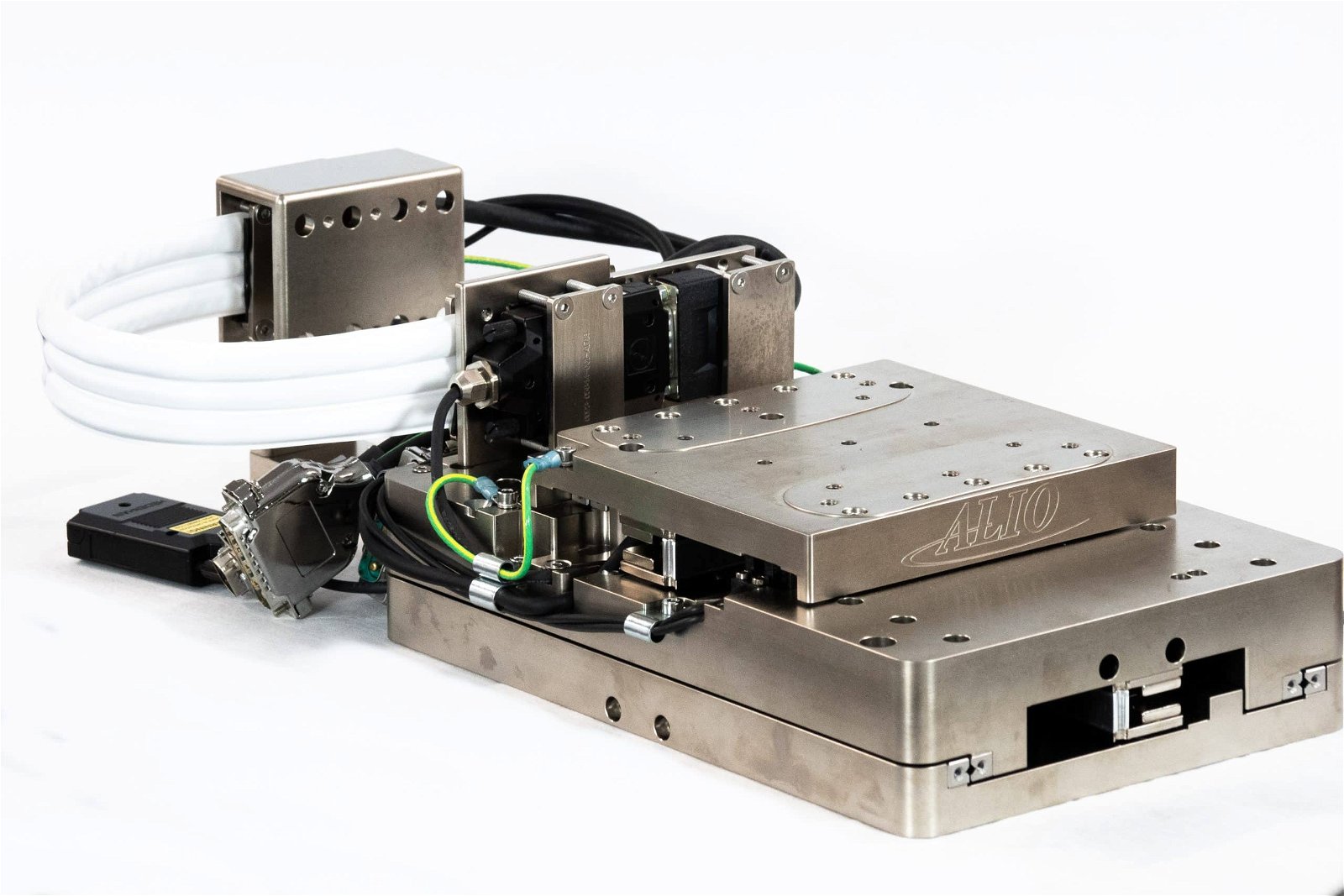

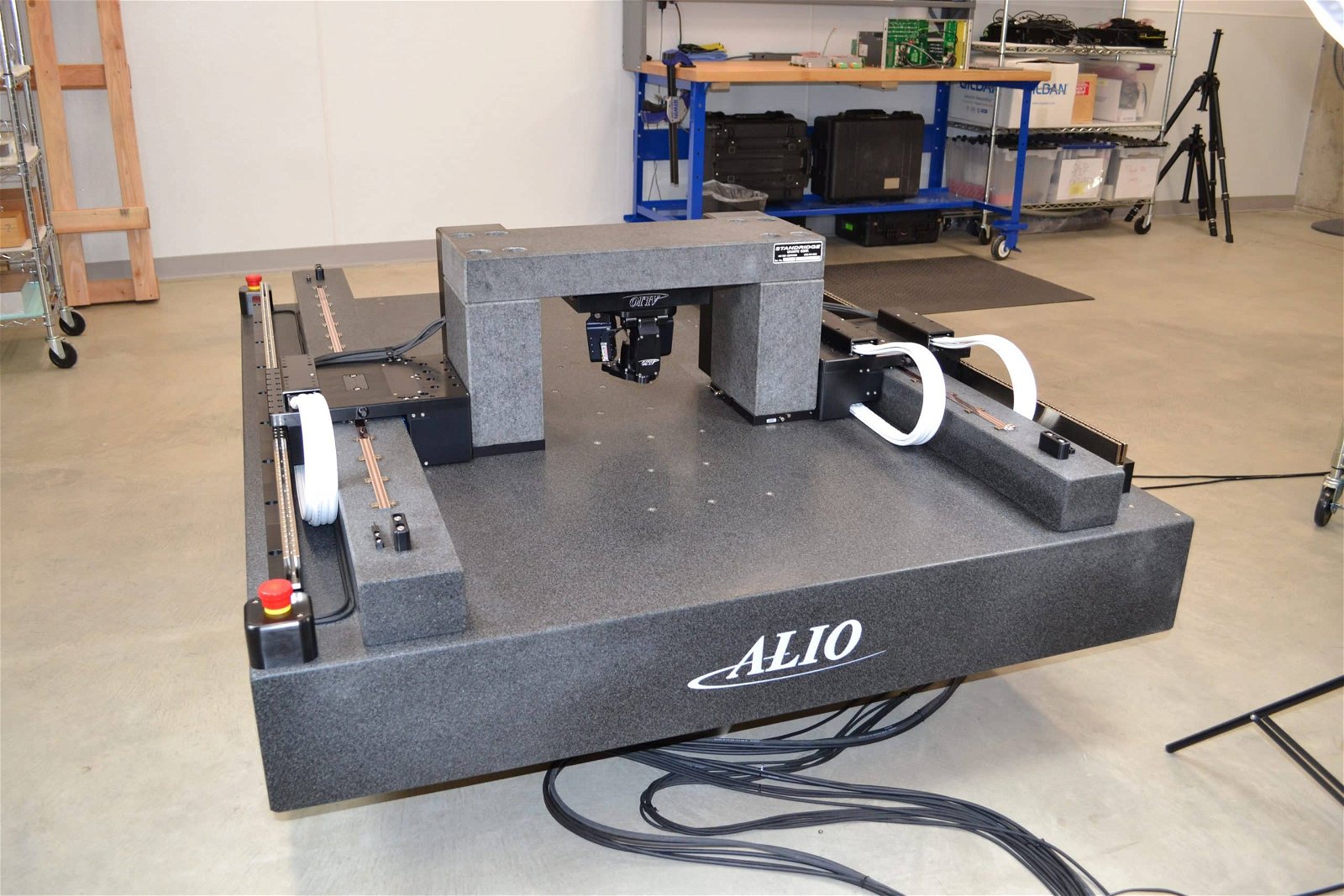

ALIO’s patented 2-axis planar XY air bearing system has set the bar in the world of 6-D Nano Positioning®. As both axes use the same highly precise granite base as reference, advanced flatness of just a single micron over several hundreds of mm (or even meters) of travel ranges can be achieved.

Thanks to ALIO’s patented design and the proprietary 6-D Nano Precision test methods, this highly stiff family of planar xy air bearing motion systems delivers sub-micron accuracy, and a +/- 100nm bi-directional repeatability even in higher quantities for serial machine production. With 200 mm to 800mm standard versions, and possible customizations to over 3 meters of X and Y travel, this product family has no equal for True Nano® precision in any kind of measurement / metrology applications and in the semiconductor industry.

Powerful linear direct drives and air bearings make these motion systems perfectly suited to high precision, high throughput applications that require smooth continuous scanning or a fast step-and-settle process over very long distances.

For more information on the planar xy air bearing stages, and the numerous customization options available, contact ALIO or have a brief look at following data sheet:

For many high-precision applications such as photonics, precision scanning in semiconductor or flat panel display manufacturing, or metrology, Linear Air Bearing stages (that float on a thin film of air) are a perfect solution.

Because the motion Is frictionless, no particles are formed, and the planar guideways they float upon are much more precise than mechanical bearings.

ALIO’s linear X Air Bearing stages are characterized by being very smooth and accurate, and provide extremely straight and flat motion. Out extremely high motion fidelity Motion Systems are based on a planar air bearing design driven by linear motors. Our Air bearing stages are used where ultra-precision is needed such in applications like wafer inspection, scribing, and flat panel inspection.

Check out some of our standard Linear X Air Bearing Stages:

Linear X Air Bearing Stages: AI-LM-(TRAVEL)00-AB

Linear X Air Bearing Stages: AI-LM-(TRAVEL)00-AB8

Box Rail Linear X Air Bearing Stages: AI-LM-(TRAVEL)00-AB-BR

ALIO’s family of linear motor driven, vertical Z-lift stages with Air Bearing counterbalance are characterized by their low profile and extremely long travel ranges. Using high precision crossed roller bearings and linear encoders, the stages are equipped with a frictionless air bearing pneumatic cylinder. Similar to the GeoSymmetric series of stages, these long travel Z stages have counterbalance, motor, bearings, and encoder all placed on an approximate centerline of the stage. Payloads may be mounted directly to the face of the stage.

The Z-ABCB series — with its frictionless air bearing pneumatic cylinder counterbalance — can carry payloads of up to 25kg over 200mm or more.

Details:

NANO Z® patented Z-lift air bearing stages overcome the legacy design issues associated with z-wedges and other vertical stages. They use a novel combination of air-bearings plus two voice coil motors in a compact footprint with up to 50mm travel.

Using air bearings means negligible friction which enables unparalleled accuracy and repeatability down to low double-digit nanometers. Variable counterbalancing easily handles heavy weights like wafer chucks, while still achieving nano-level precision over the full travel range.

The Nano Z® design places vertical force in line with the payload, and this makes it possible to place the stage directly below the payload instead of beside it, avoiding inevitable cantilever inaccuracies and nearly eliminating pitch, yaw and roll.

Dimensions and specification can be found in following data sheet:

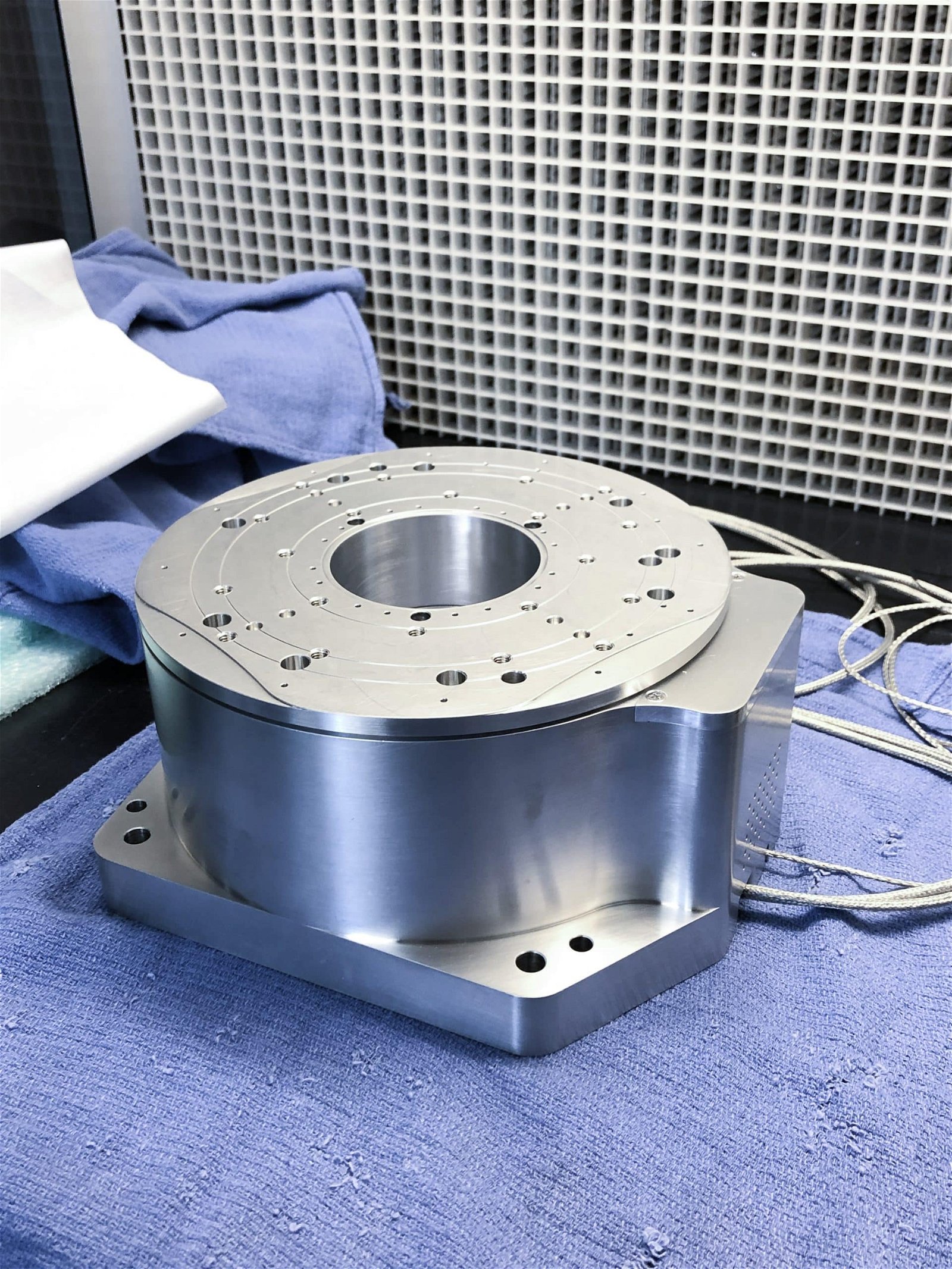

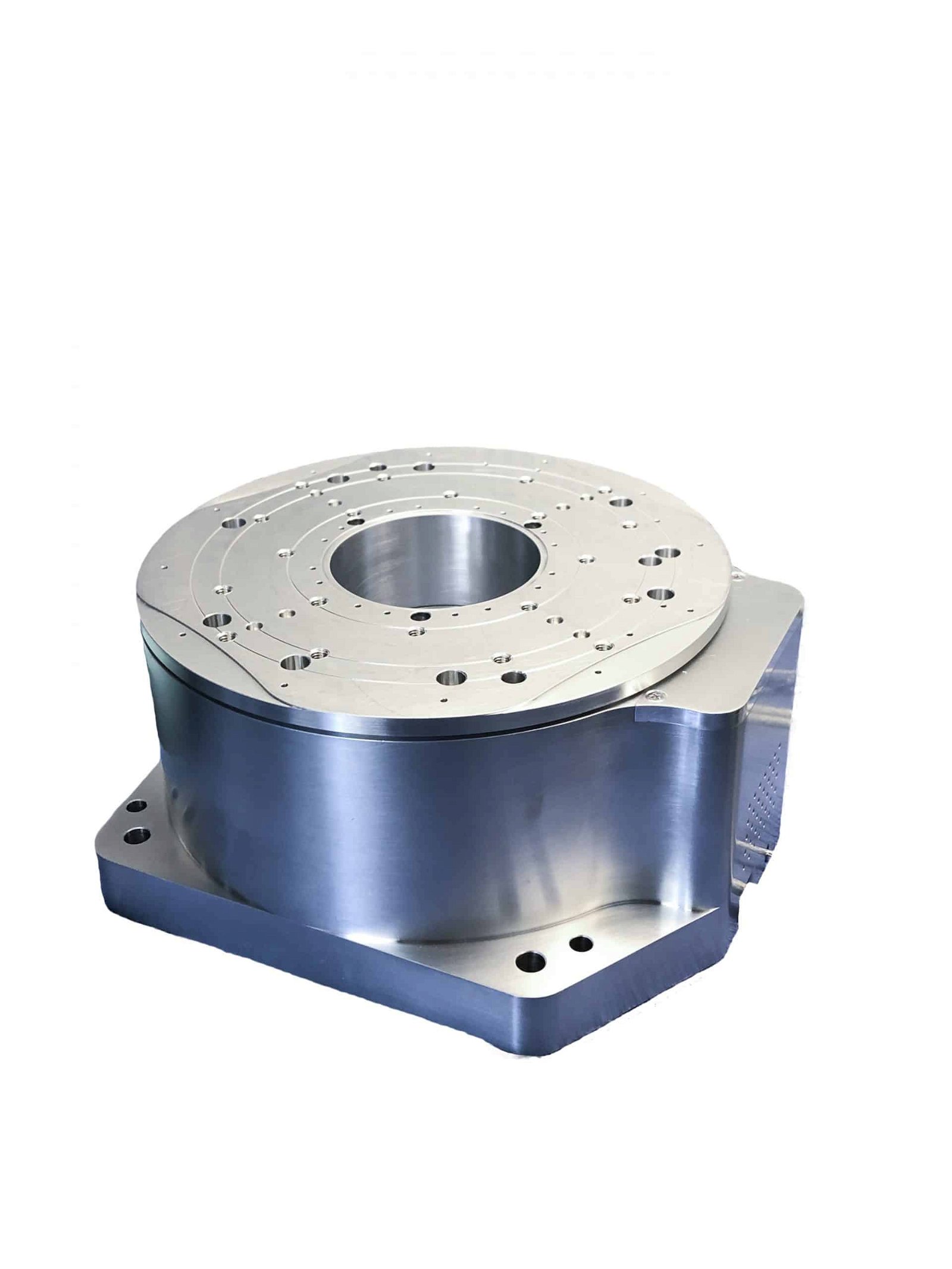

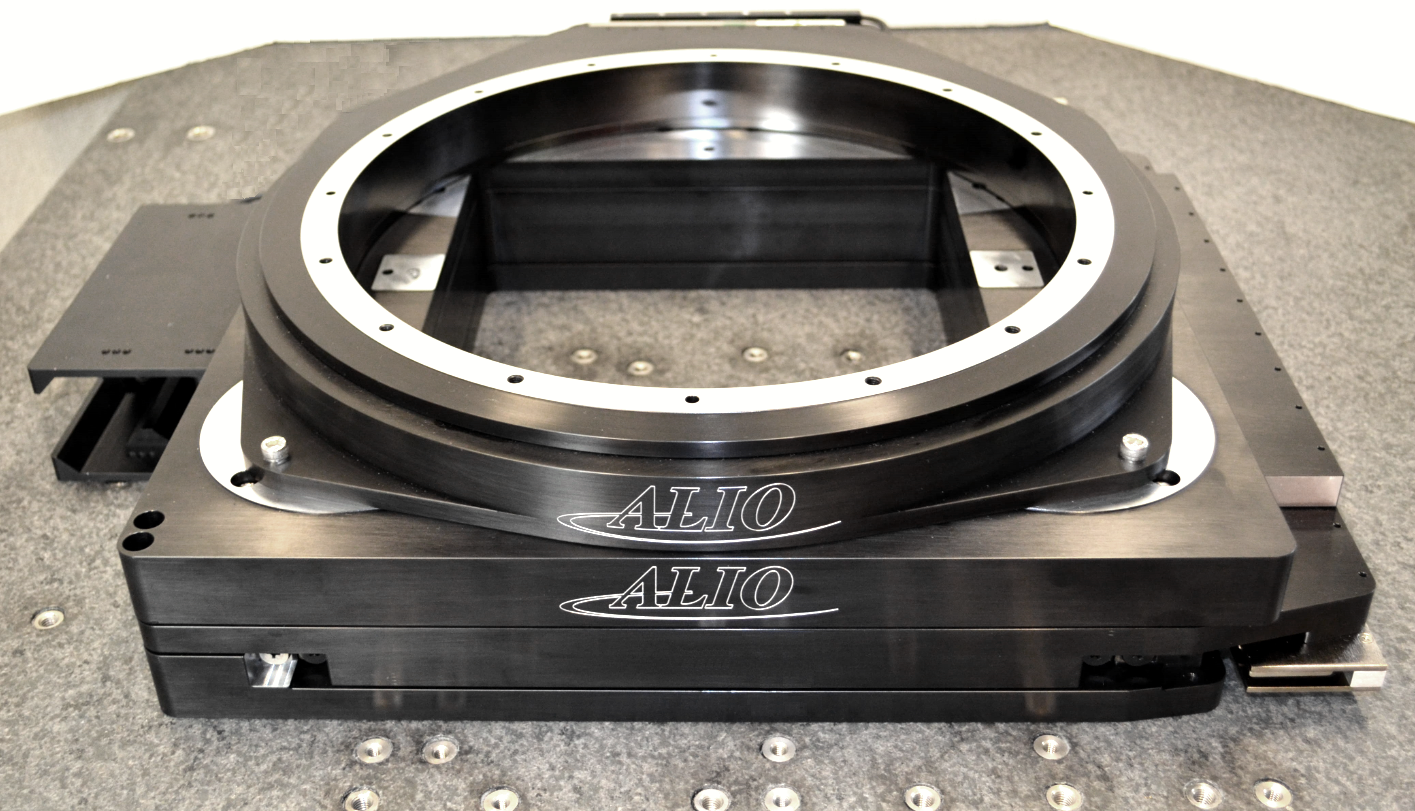

When the highest rotational precision is required, manufacturers can choose from ALIO’s line of air bearing rotary stages. Air bearings allow the stage to move without mechanical contact and therefore movement is frictionless and without wear. Errors like wobble, eccentricity, or runout can be minimized to get close to a perfect, smooth 360 degree movement even at high speeds or when the rotational stage is mounted vertically. Thanks to powerful torque motors, both constant continuous rotation as well as step-and-settle processes can be performed in an equally precise and reliable way.

It is no surprise that ALIO’s rotational air bearing stages can therefore be found in the most precise applications within the semiconductor, metrology, and photonics industries.

For detailed specifications please download the following spec sheets:

NANO Z® patented Z-lift air bearing stages overcome the legacy design issues associated with z-wedges and other vertical stages. They use a novel combination of air-bearings plus two voice coil motors in a compact footprint with up to 50mm travel.

Using air bearings means negligible friction which enables unparalleled accuracy and repeatability down to low double-digit nanometers. Variable counterbalancing easily handles heavy weights like wafer chucks, while still achieving nano-level precision over the full travel range.

The Nano Z® design places vertical force in line with the payload, and this makes it possible to place the stage directly below the payload instead of beside it, avoiding inevitable cantilever inaccuracies and nearly eliminating pitch, yaw and roll.

Dimensions and specification can be found in following data sheet:

ALIO’s GeoSymmetric™ Vertical Positioning Stages use voice coil or linear direct drives, high precision crossed roller bearings, and various counterbalance options within a unique and innovative design concept.

Unique geometric shapes provide mounting surfaces on multiple faces of the stage for flexible installation options. Being able to mount the payload directly to the face or top surface of the stage helps to eliminate weakness and resonant frequency issues associated with additional brackets.

The “Symmetric” part of the family’s name originates from the arrangement of the components used. The counterbalance, motor, bearings, and encoder are all placed on an approximate centerline of the stage, i.e. they are integrated in a way that their masses are symmetrically distributed over the stage.

This series of stages has been built for precision with application dependent counterbalances, and has been structurally designed to exceed application performance demands (with bidirectional repeatability down to +/-45nm, travels from 6 to 70mm, and load capacities of up to 30kg). Being 4x to 10x more precise than Z-wedge stages makes ALIO’s GeoSymmetric™ Vertical Positioning Stages great for any application within the semiconductor industry, microscopes for life and health science, or numerous metrology applications.

Explore our many options with a closer look at the relevant data sheets:

Pneumatic Counterbalanced Z: AI-(MOTOR)-(TRAVEL)00-(FORCE)-Z-CB

High-Force Pneumatic Counterbalanced Z: AI-(MOTOR)-(TRAVEL)00-(FORCE)N-Z-CB

Magnetic Spring Counterbalanced Z, Voice Coil: AI-(MOTOR)-(TRAVEL)00-(PAYLOAD)-Z-MCB-(ORIENTATION)

Mini Z with user-swappable Spring Counterbalanced Z: AI-(MOTOR)-(TRAVEL)00-Z-SCB

ALIO’s family of linear motor driven, vertical Z-lift stages are characterized by their low profile and extremely long travel ranges. Using high precision crossed roller bearings and linear encoders, the stages are equipped with magnetic spring counterbalances or a frictionless air bearing pneumatic cylinder. Similar to the GeoSymmetric series of stages, these long travel Z stages have counterbalance, motor, bearings, and encoder all placed on an approximate centerline of the stage. Payloads may be mounted directly to the face of the stage.

The Z-MCB versions with magnetic spring counterbalances allow travel between 25 and 170mm, while the Z-ABCB — with its frictionless air bearing pneumatic cylinder counterbalance — can carry payloads of up to 25kg over 200mm or more.

Details:

Magnetic Spring Counterbalanced Z, Linear Drive; AI-LM-(TRAVEL)00-Z-MCB-(MAX PAYLOAD)

A broad field of applications from industrial automation to large measurement or metrology tools demand enormous lift capabilities while still achieving nanometer precision. For such applications, ALIO offers vertical Z stages with precision ball screws driven by a frameless torque motor that is equipped with pneumatic release spring engage brakes that lift 20kg without additional counterbalance. For even higher loads, this series offers the so-called “pneumatic boost” option which uses a frictionless pneumatic counterbalance to boost the payload capability to 50kg.

Even with such high loads, these stages can achieve +/- 100 nm bi-directional repeatability over ranges of up to 50mm. This makes it the ideal stage for applications requiring high loads and long travel ranges without compromising precision.

More information on precision, accuracy and motion profile specifications:

When looking at most imaging applications, optimal focus of the image can only be achieved if the distance between the sample and the optics is adjustable. Typically, a Z-axis focusing stage would be used for such applications with either the sample or the optics being moved along the optical axis. The specifics of the application, the optics, and the sample will ultimately determine the range of motion required, with some examples where additional focus travel is needed being:

• For thick or non-planar samples such as tissue samples or cultured cells

• For non-parfocal objectives each of which have a different focus spacing

• Where there are multiple sample types such as microscope slides or microtiter plates

• When it is necessary to retract the optics during a load/unload operation

Some other advanced microscopy applications require that a series of images are acquired, each separated by a small increment along the Z-axis, such advanced focus control being needed to create 3D sample images.

For all such exacting applications, ALIO’s direct drive focus stage technology is up to the challenge:

Z Focusing Stage: AI-VC-600-SCB-ATRAK

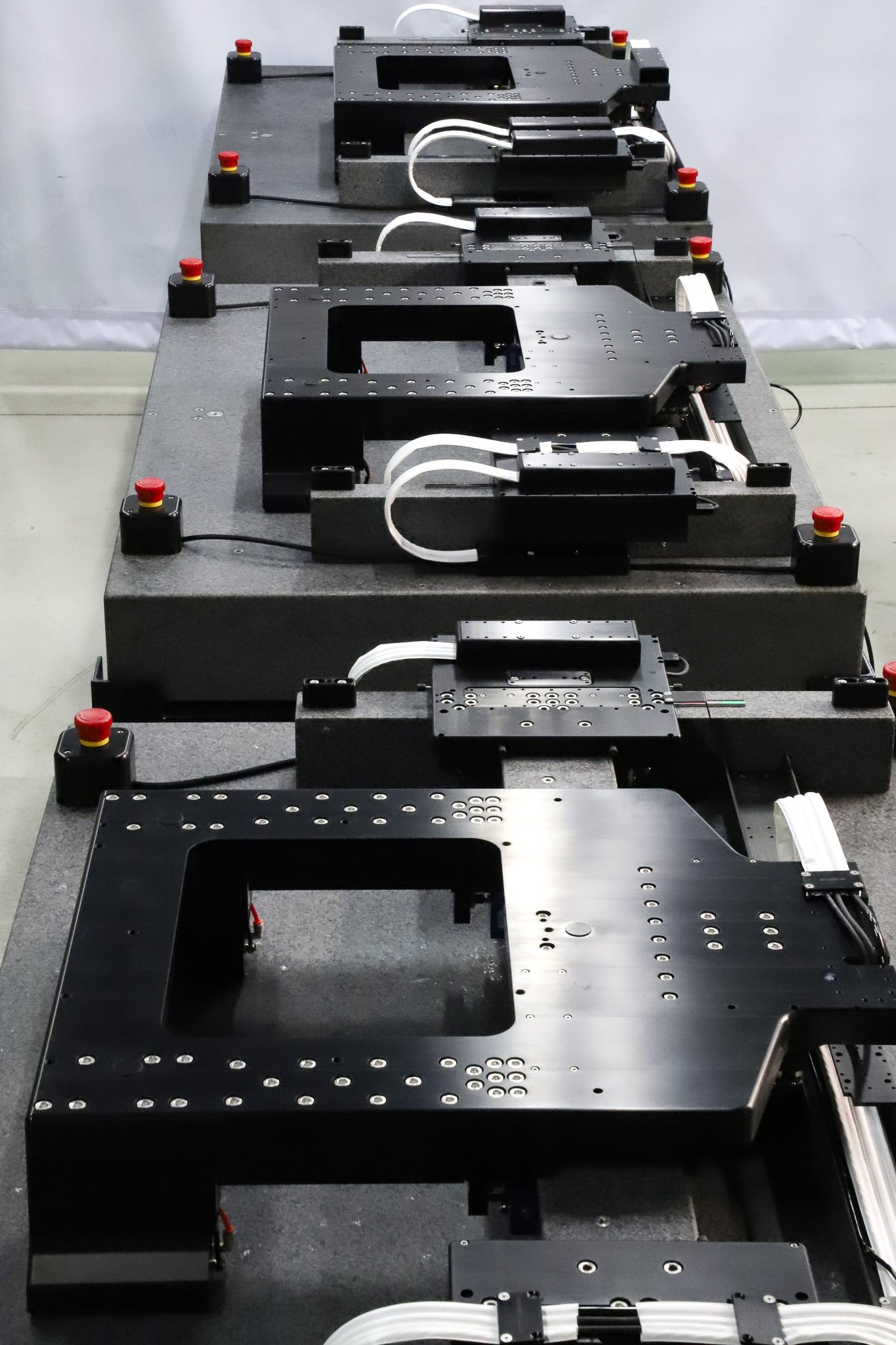

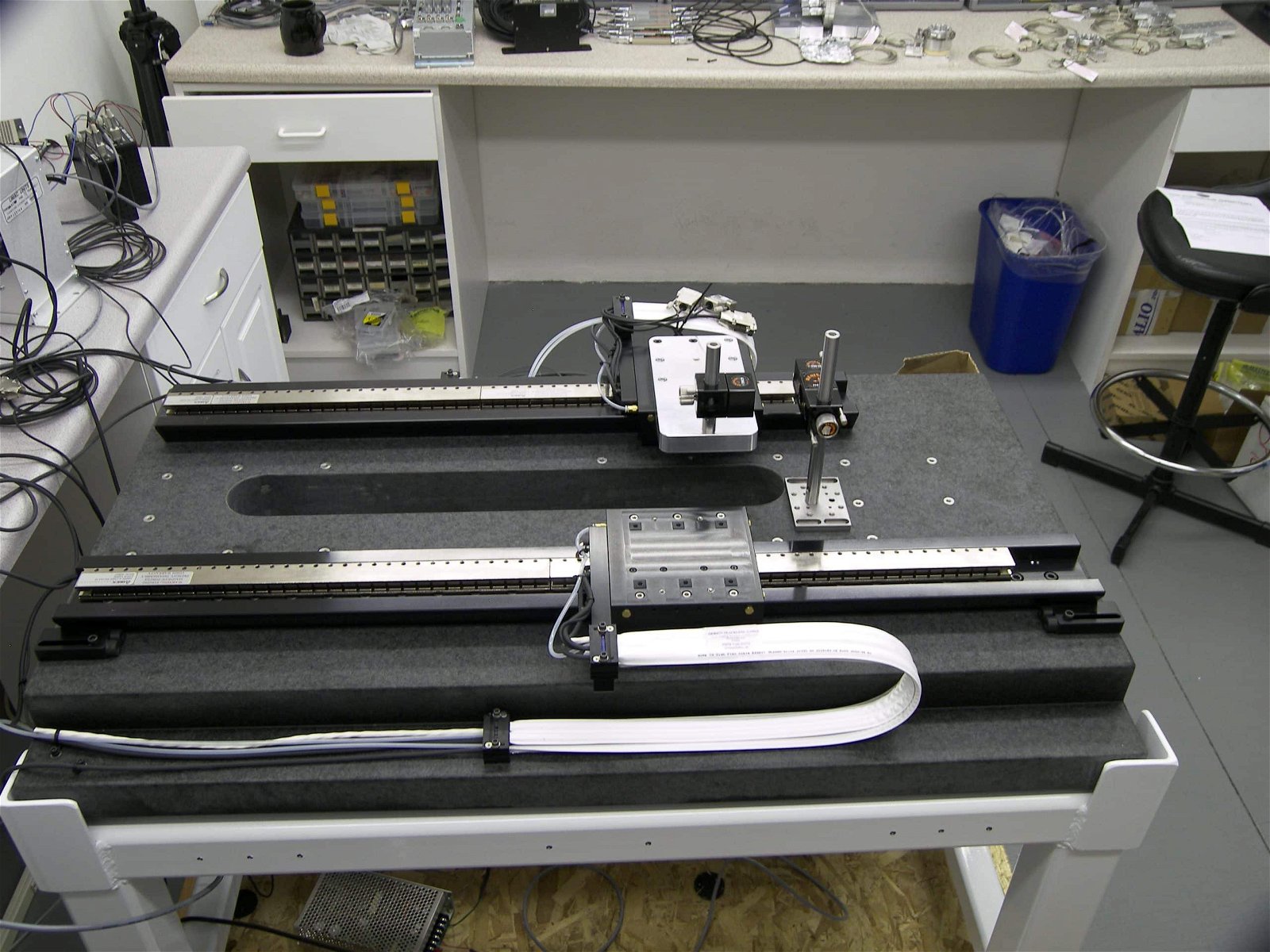

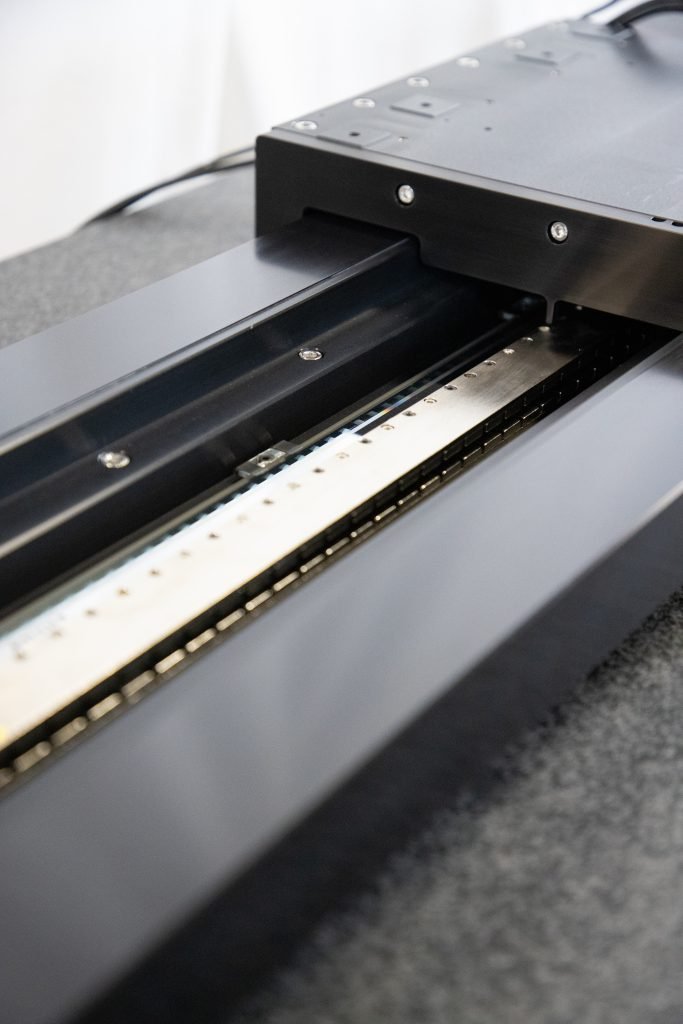

ALIO Industries offers a series of linear motion systems that combine linear direct drives with dual recirculating ball rails, providing precision and flexibility to a wide range of applications. This system architecture allows customers to achieve micron-to-nanometer precision while overcoming budget constraints and exceeding the travel possible using crossed roller bearings.

The series includes nine standard stages with flexible travel ranges from 100mm to 700mm, and they can be used not only when mounted on a flat horizontal surface, but also when used on vertical surfaces or even inverted. The stages are designed with high-flex cabling, hard stops, high-resolution encoders, optical latching home index, and end-of-travel limits to ensure robust and precise motion.

For more information, take a closer look at the datasheet provided by ALIO Industries.

ALIO Industries offers two lines of “Slim” Micron 2 (µII) motion systems, featuring recirculating ball rail bearings and linear direct drives. These stages are available in compact or “naked” versions and are ideal for use in Cartesian Gantry systems.

With travel ranges of up to 1m and a slim profile of just 72mm width and 57mm height, these stages are an excellent choice when space is limited. Achieving a +/-0.5µm bi-directional repeatability, they offer excellent precision without compromising on size. ALIO’s proprietary design and manufacturing processes ensure superior flatness and straightness.

Check out the datasheets for more information:

Micron 2 Slim Rail Linear X: AI-LM-(TRAVEL)00-uII-S

Micron 2 Slim (Naked) Rail Linear X: AI-LM-(TRAVEL)00-uII-SN

These three series of products are designed for extreme applications. They can carry heavy, large objects, targets, and products and can be used over extra-long ranges. Equipped with dual recirculating bail rail bearings, driven by a linear direct drive, these robust stages can reach lengths of up to 2m on which with carrier plates up to 300mm wide and either 170mm, 270mm or even 306mm long.

It is therefore not surprising that all these stage can carry payloads of up to 100kg and achieve acceleration of 2.0 G -4.0 G.

What is perhaps more surprising, however, is that customers can still expect a bi-directional repeatability of less than +/-0.5µm and 1-digit micron and arc-sec in flatness, straightness, pitch, yaw and roll.

All details can be found on the datasheets:

Micron 2 Wide Dual Rail Linear X: AI-LM-(TRAVEL)00-uII-W

For certain applications, an electromagnetic linear direct drive might not be ideal. This is specifically true for applications that require the ability to hold position (literally no movement on power loss) even during a sudden or necessary power stop or loss. This is often critical when high payloads (but not only high payloads) are involved, or if a stage needs to be mounted other than horizontally.

ALIO has therefore extended its range of stages suitable for these kinds of challenges with further Micron 2 (µII) motion systems. Those stages known as the “SBS” and “XBS” series use a frameless torque motor that drives the carrier with a precision ball screw on dual recirculating ball rail bearings. For further strength, certain stages can be equipped with brake options contributing to the safety of the machines.

Even with this combination of drive and bearings, the stage will successfully accomplish applications requiring a bi-directional repeatability of only +/-1 µm. The ball screws anti-backlash nut ensures any backlash is avoided.

Further information concerning linear displacement accuracy, resolution, flatness, straightness or pitch, yaw, and roll can be found in the specific datasheet available for download:

ALIO’s Micron 2 Rotary Stages utilize frameless torque motors and angular contact, duplex pair bearings. These stages are designed to achieve maximum possible throughput without compromising on precision, regardless of whether the application requires a smooth, continuous movement or a fast step and settle process. Also allowing decent sized apertures, those rotational stages are used in a broad selection of applications and industries such as industrial manufacturing, photonics or semiconductor metrology.

ALIO Industries offers a range of precision rotary stages that are designed to meet the most demanding applications. Our standard rotary stage family uses crossed roller bearings and frameless torque motors to provide extreme throughput, acceleration, and mass capabilities while maintaining nanometer-level precision. These rotary stages are also highly stiff and can handle offset loads with ease.

Our crossed roller bearing rotary stages have +/-0.2 arc-second repeatability and are rated at 13 to 20 microns of radial and axial run-out. Some models even offer run-outs below 5 microns. We also offer mechanical bearing rotary stages in different sizes to meet varying duty cycles, mass, and acceleration needs, ranging from 80 mm to 300 mm in diameter. For mounting a vacuum chuck, vacuum rotary union options are available on the inner diameter.

Explore ALIO’s range of crossed roller bearing and mechanical bearing rotary stages to find the perfect solution for your rotary motion system needs.

Need more details?

ALIO Industries offers mechanical bearing rotary stages with angular contact bearings to meet the requirements of applications that demand a compact and flat rotary stage with a decent aperture size. With torque motors, these stages enable a smooth continuous movement or a step-and-settle process over the full 360 degrees, without compromising precision or throughput. The stages are highly versatile and suitable for various industries and applications.

To know more about this family of stages, check out the spec sheet.

360 degree Angular Contact Bearing Stages: AI-TM-(DIAMETER)RA

ALIO Industries offers a line of air bearing rotary stages for manufacturers that require the highest rotational precision. These stages move without mechanical contact, resulting in frictionless and wear-free movement. ALIO’s air bearing rotary stages can minimize errors such as wobble, eccentricity, or runout to achieve near-perfect, smooth 360-degree movement even at high speeds or when mounted vertically. Equipped with powerful torque motors, these stages can perform both constant continuous rotation and step-and-settle processes with equal precision and reliability.

It’s no wonder that ALIO’s air bearing rotary stages are commonly used in highly precise applications within the semiconductor, metrology, and photonics industries. For detailed specifications, download the following spec sheets:

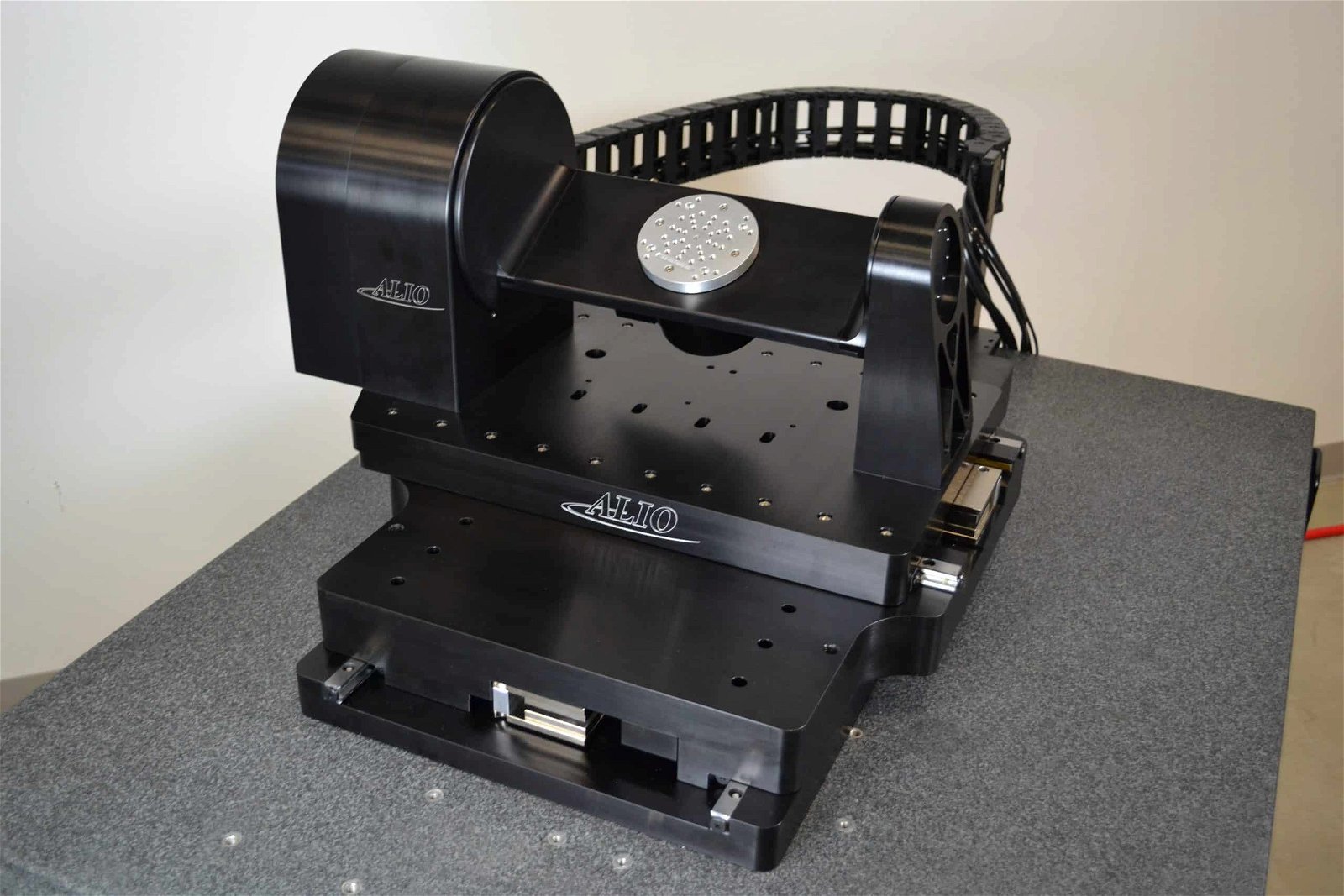

ALIO Industries offers industry-leading torque ratings with its two-axis gimbal rotary systems, delivering high rotational speeds without sacrificing precision. The systems can be customized for each customer’s mass, with variable counterbalance, cable guidance, and cable and air feed-through capabilities. The dual-axis rotary systems allow for +/-110 and +/-170 degrees of rotation on the horizontal axis, while exhibiting angular travel +/-180 degrees for rotation about the vertical axis. An air purge is incorporated to protect against contamination and maximize lifespan.

ALIO’s 2-axis gimbal rotary systems have been utilized in a range of industries, including metrology, laser processing, and additive manufacturing. For more detailed specifications, please refer to the spec sheet.

ALIO Industries’ open-center rotary stages utilize tangential linear direct drives with angular contact bearings for up to +/-7.5 degrees of angular movement and an extreme aperture. These stages are ideal for high-precision applications, including the semiconductor, metrology, and life science industries. With rigid bearings and a powerful linear direct motor, they are designed to meet the high-throughput needs of the high-precision market.

Download our product spec sheet for more details.

ALIO Industries’ linear X stages are the ideal choice for precision applications, as they are commonly used in the precision industry due to their reliability and performance. The family of stages offers a wide range of travel options from 30mm to 300mm by utilizing two types of linear direct drives: the “LM” and the “CM” series.

The “LM” series provides greater force, higher acceleration, greater speed, and supports payloads of up to 50kg, while the “CM” series offers a low-profile design for tools and applications with space constraints, without compromising precision. ALIO’s linear motion systems and linear X stages are the perfect choice for applications that require precision and reliability.

For more information please download and analyze the following datasheets:

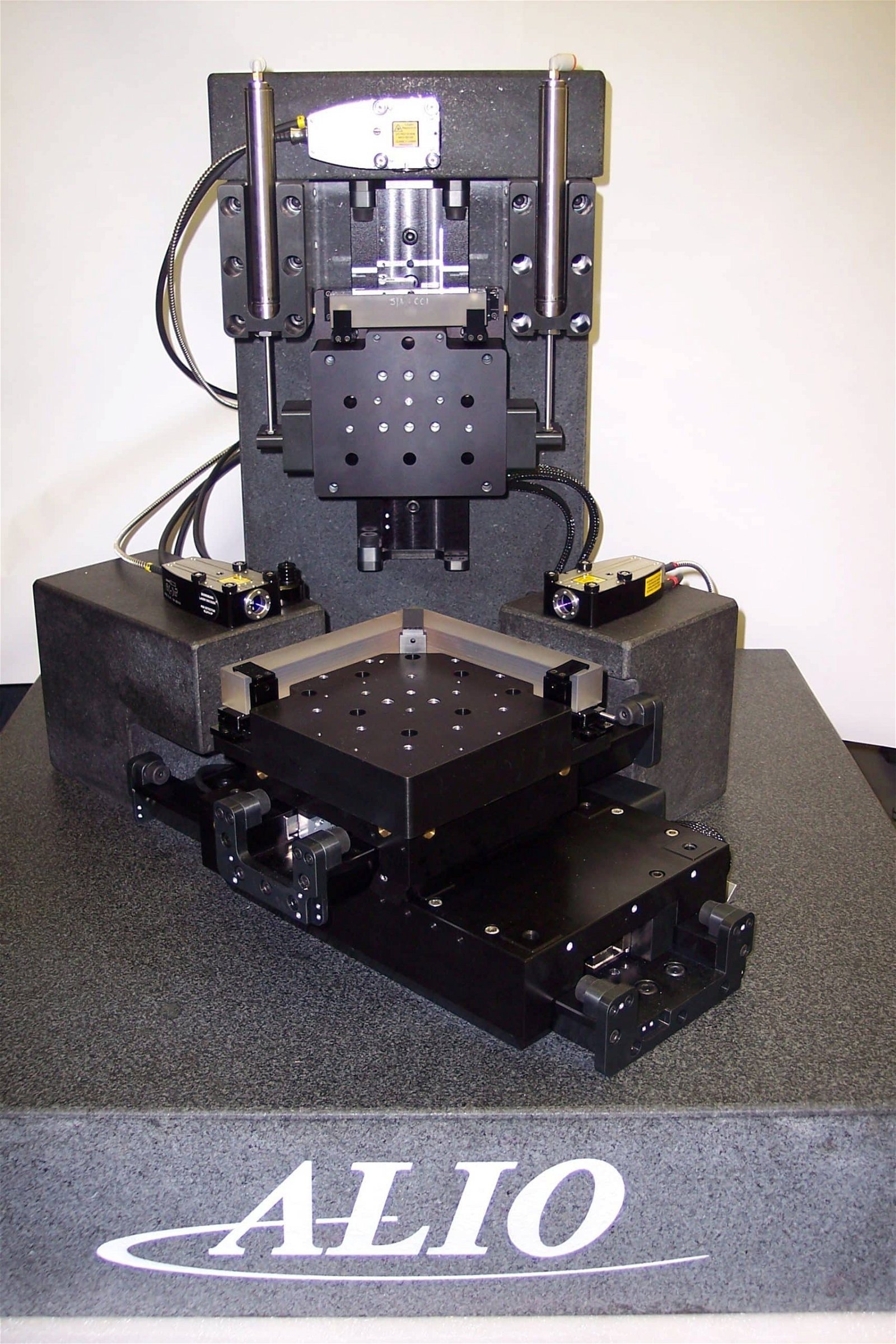

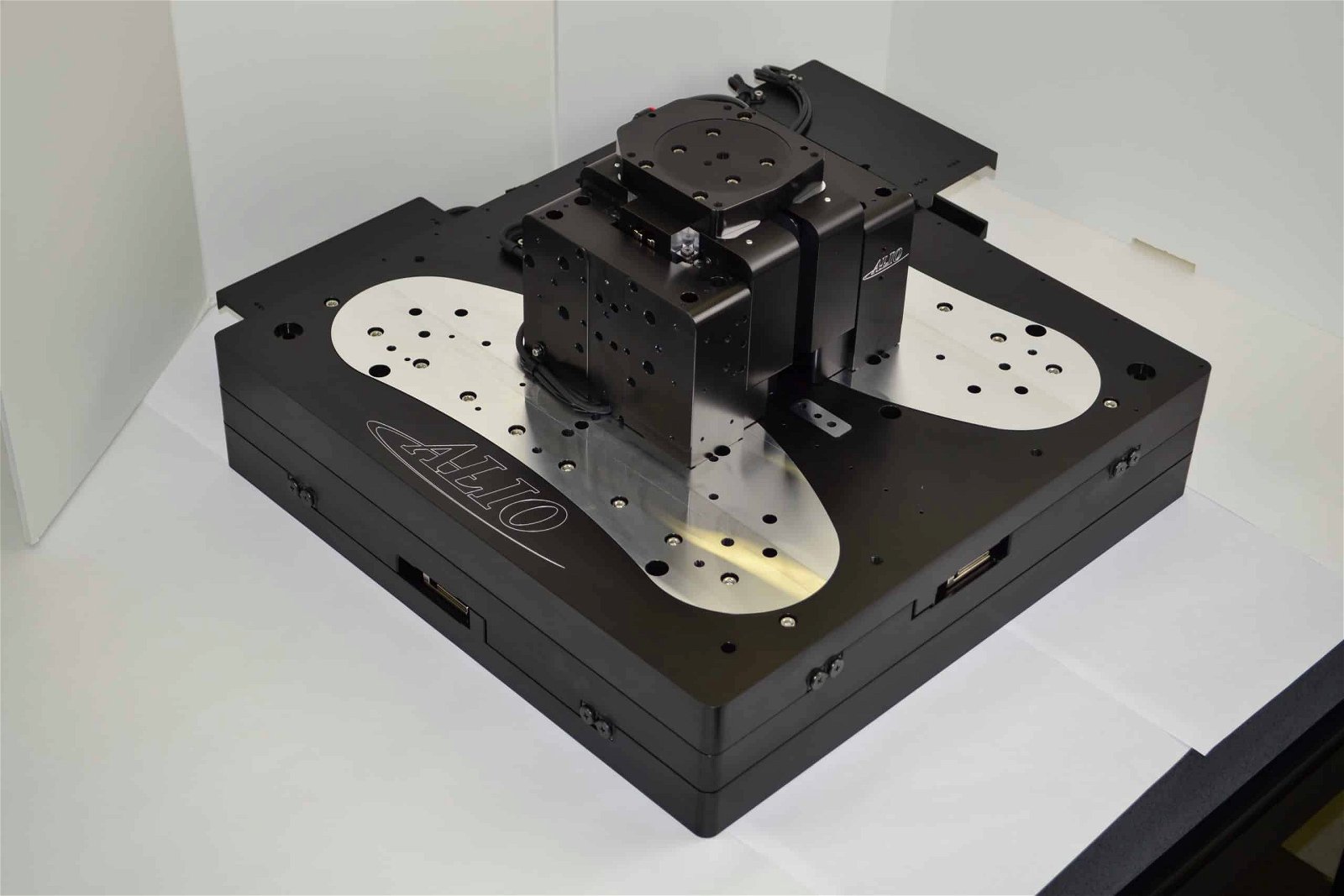

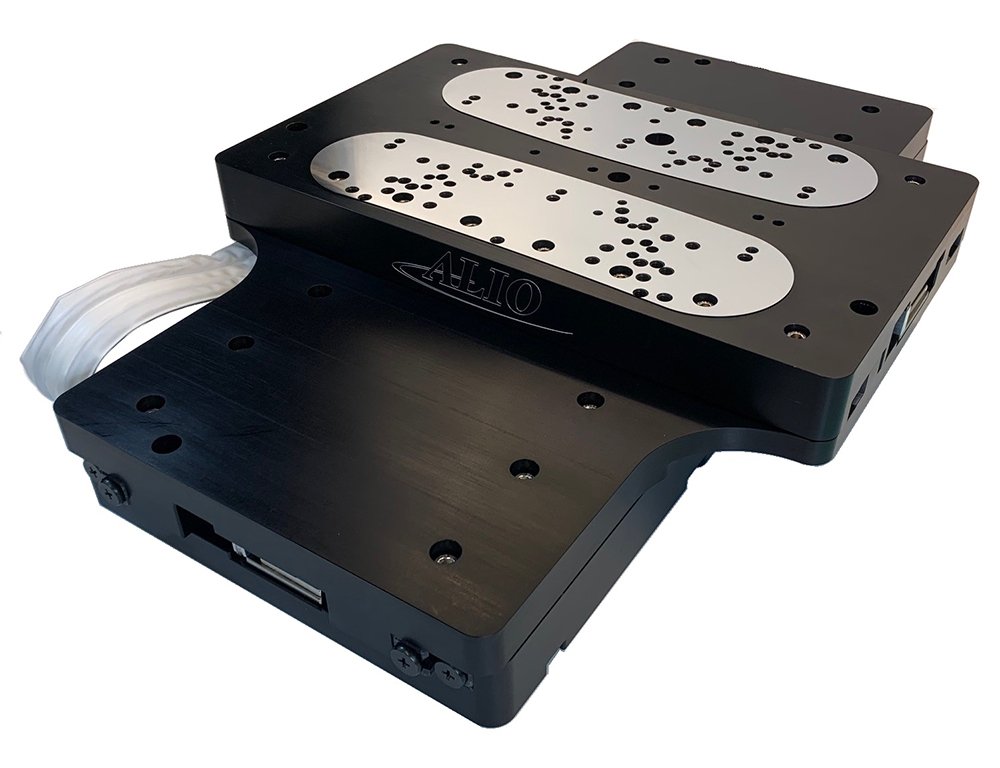

ALIO Industries offers enclosed, monolithic XY stages that are suitable for ultra-precise applications. These stages feature direct linear drives and high-precision crossed roller bearings built into a compact 3-plate system. With nanometer straightness and flatness, as well as optimized orthogonality, the point precision is True Nano®. Standard travel ranges are from 30mm up to 400mm, and stages can be built for high vacuum or clean room applications if needed.

The bi-directional repeatability of these stages is only +/- 30nm, making them suitable for scanning applications requiring a smooth, continuous movement, or for fast step and settle processes when high output is required. The enclosed, monolithic XY stages are available in two series – the standard LM-series and the low-profile CM-series.

For more information, download the datasheets available on our website.

To download datasheets, look for:

ALIO Industries produces open-centered, monolithic XY stages with large apertures for accessibility from all sides. These stages use powerful direct linear drives and high-precision crossed roller bearings in a 3-plate system to achieve outstanding precision. With a bi-directional repeatability of just +/- 50nm, superior straightness and flatness, and optimized orthogonality, ALIO’s open-centered XY stages offer Nano Precision® with travel ranges of 30mm to 400mm. The stages are perfect for scanning applications requiring smooth, continuous movement and fast step and settle processes, and increase throughput substantially. They can be built for high vacuum or clean room applications. ALIO’s open-centered XY stages are available in standard LM-series or the more compact CM-Series. Download datasheets on our website.

Open-Centered Monolithic XY: AI-LM-(TRAVEL)00-(THRU)E-XY

Low-profile Open-Centered Monolithic XY: AI-CM-(TRAVEL)00E-(THRU)-XY

If you need a low-profile solution to avoid space constraints, require different travels in X and Y, and can’t compromise on performance and precision, there are hardly any off-the-shelf products on the market. ALIO’s asymmetrical, monolithic XY stages are unique in the market and can help solve this complex combination of motion requirements.

With linear direct drives, ultra-precise crossed roller bearings, and our 3-plate system, we guarantee highly precise and powerful motion, as well as perfect orthogonality of the X and Y axes in respect to each other.

“Asymmetrical” in this design concept refers to the two different travel ranges of these two stages that are usually achieved by mounting different linear X stages on top of each other.

For further information, contact us or download the following specification sheets:

Asymmetrical, Monolithic XY: AI-LM-(TRAVEL_X)x(TRAVEL_Y)-XY

Asymmetrical, Monolithic XY: AI-SLM-(TRAVEL_X)x(TRAVEL_Y)-XY

ALIO’s precision ball-screw driven X stages are perfect for applications that require precision despite electrical noise. These stages are driven by a torque motor that moves a precision ball screw with an anti-backlash nut, and they can be equipped with pneumatic or electric solenoid brakes if necessary.

Thanks to ALIO’s unique design and manufacturing principles, these stages achieve a bi-directional repeatability of only +/- 100nm, with straightness and flatness well below 5µm (and on request even 1µm can be maintained).

Off-the-shelf versions are available for travels of 30mm, 100mm, 150mm, and 200mm, and can be realized for ambient, high vacuum, and clean room conditions.

For more information on these stages, please refer to the following datasheet:

Linear X with Precision Ball Screw:_AI-VBS-(TRAVEL)00-(BRAKE OPTION)

ALIO has introduced the Micron 2 (µII) motion systems family to compete in the micron-level motion control market. These systems are designed to offer low-cost, mid-precision, reliable, and long-travel stages. As with all ALIO’s products, the Micron 2 (µII) systems are designed with the company’s “quality first” standards, ensuring long-term reliable operation.

The Micron 2 (µII) recirculating ball rail bearing stages come in standard sizes of 100mm up to 2 meters, making them suitable for a wide variety of applications. This family of motion systems is robust and powerful, designed for use either as a stand-alone unit or as a top axis of an integrated solution.

For more details, visit the dedicated Micron 2 (µII) motion systems page.

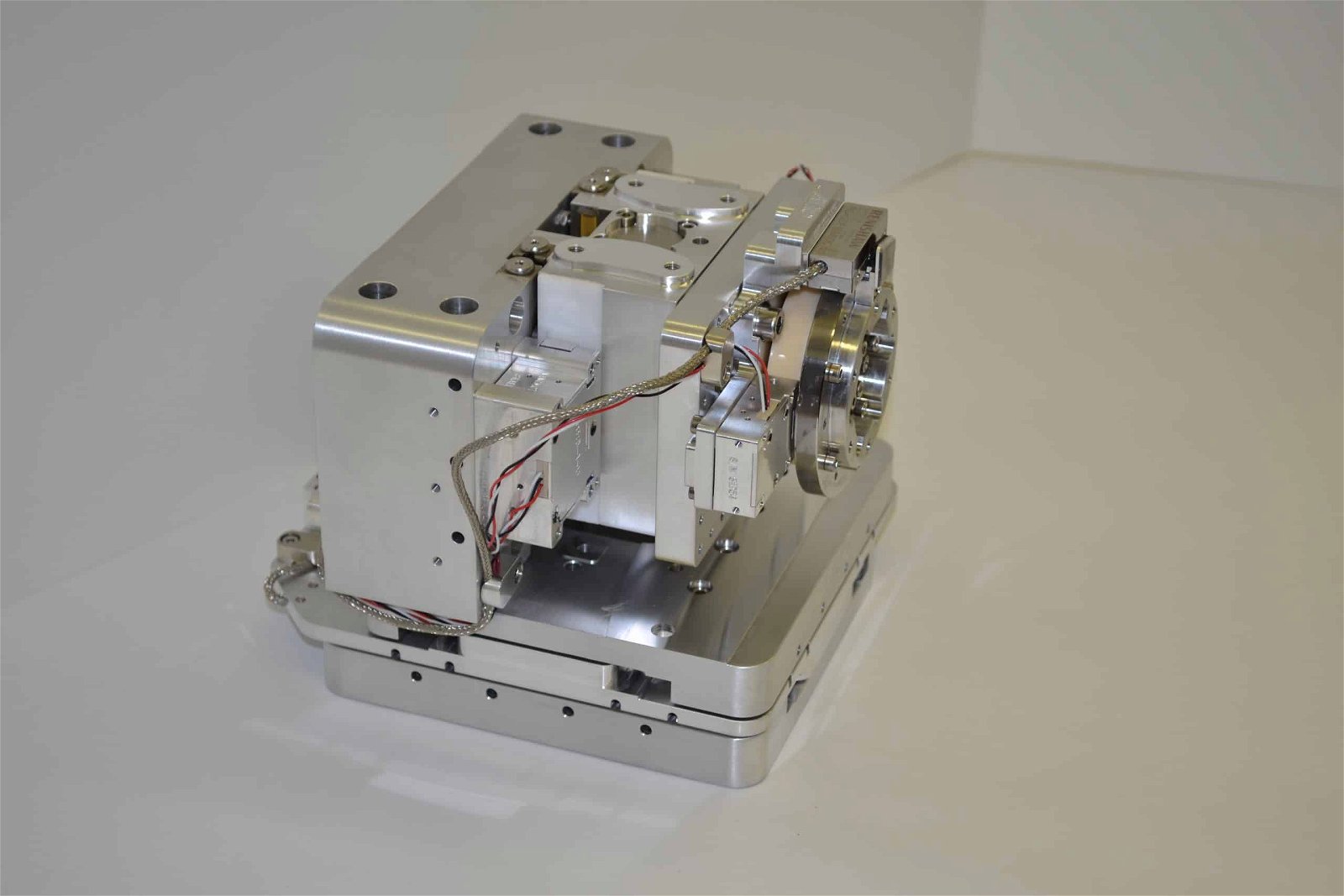

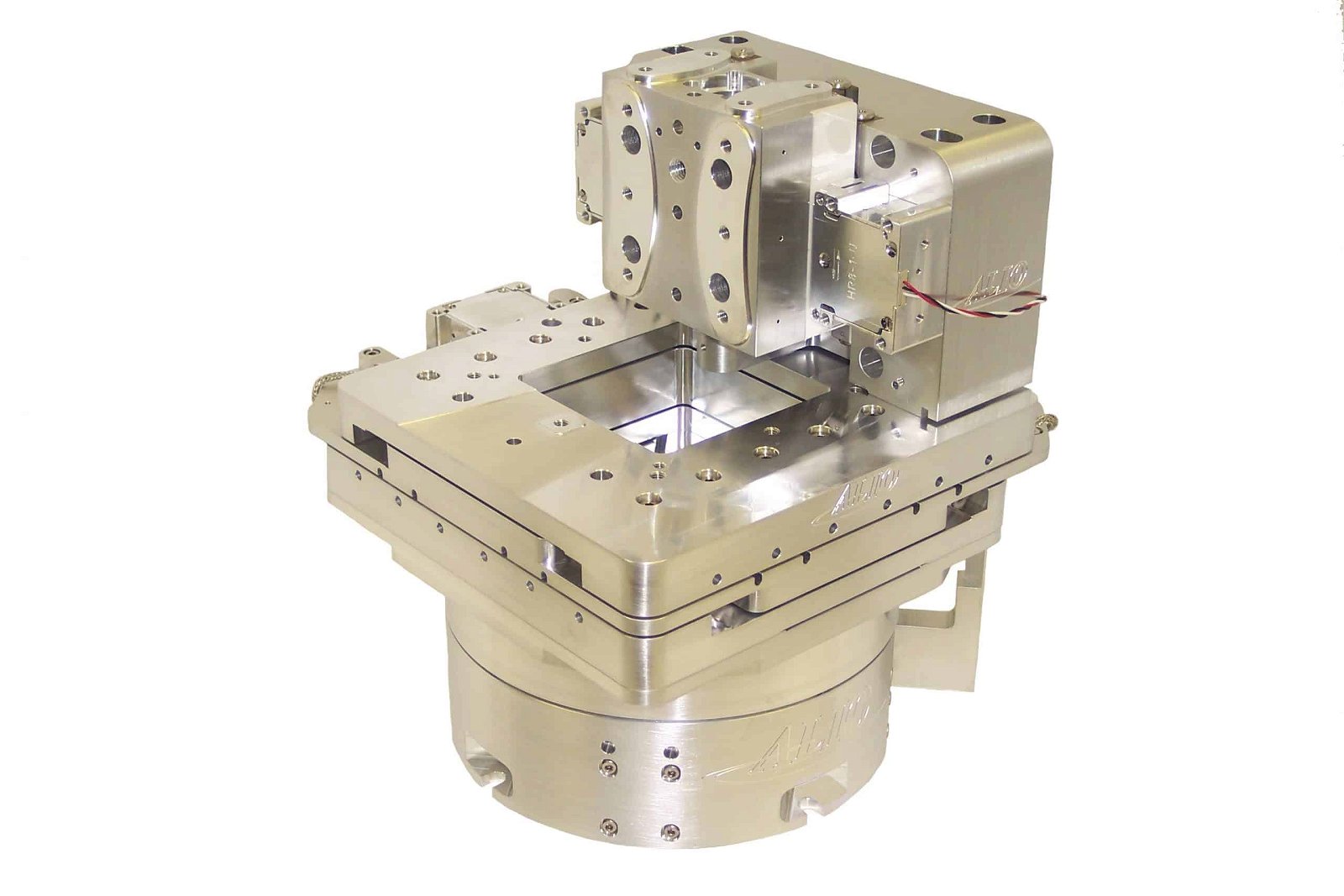

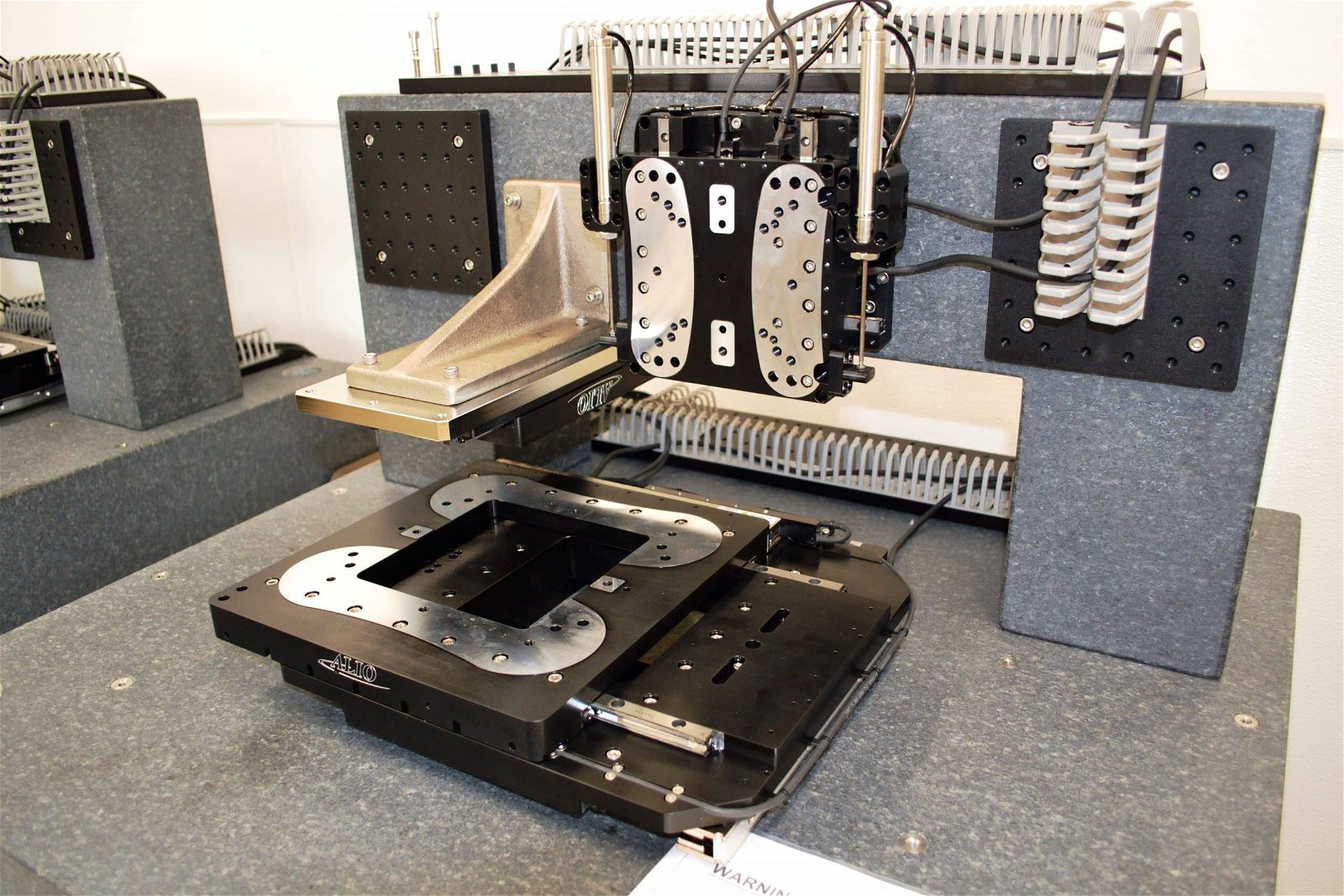

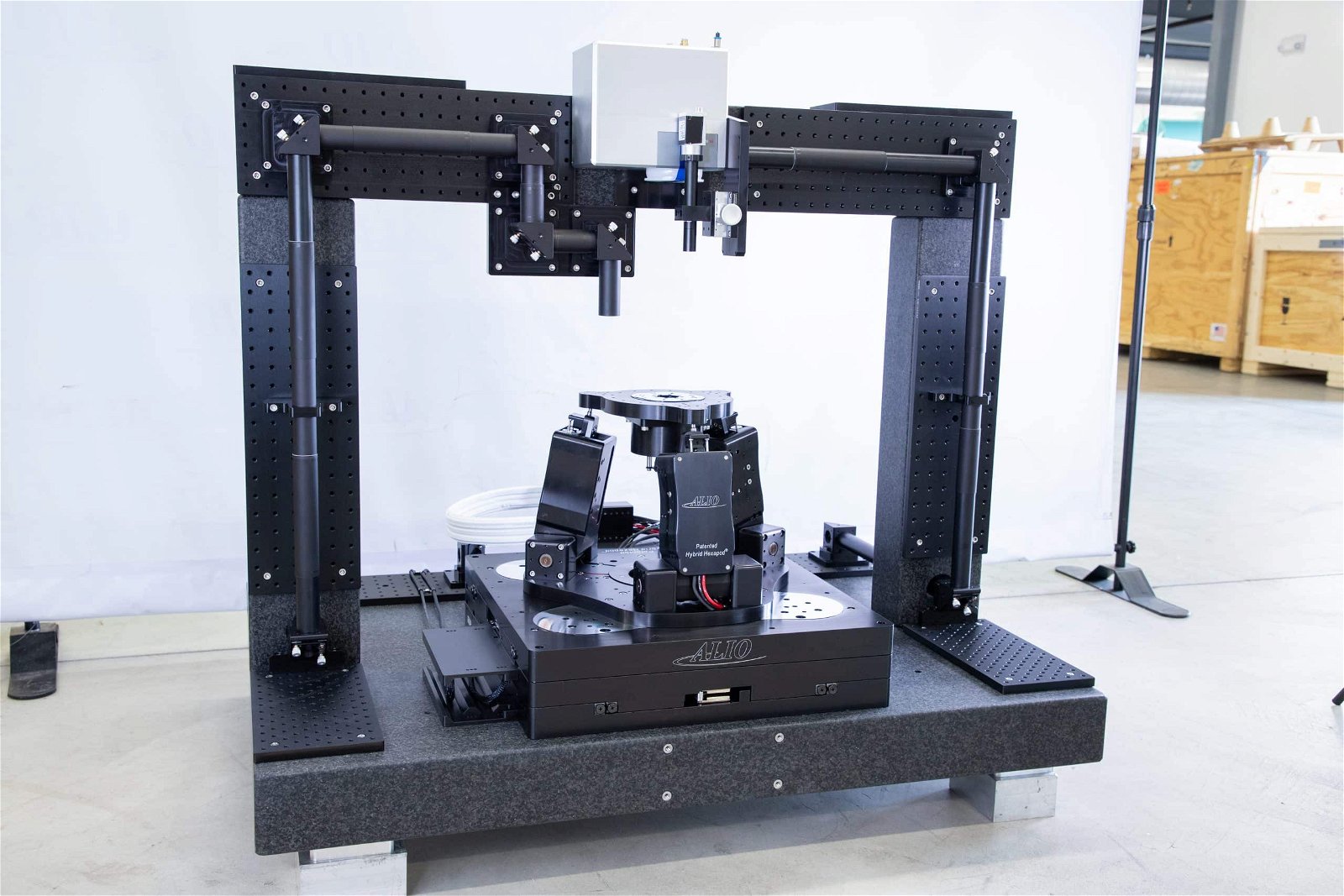

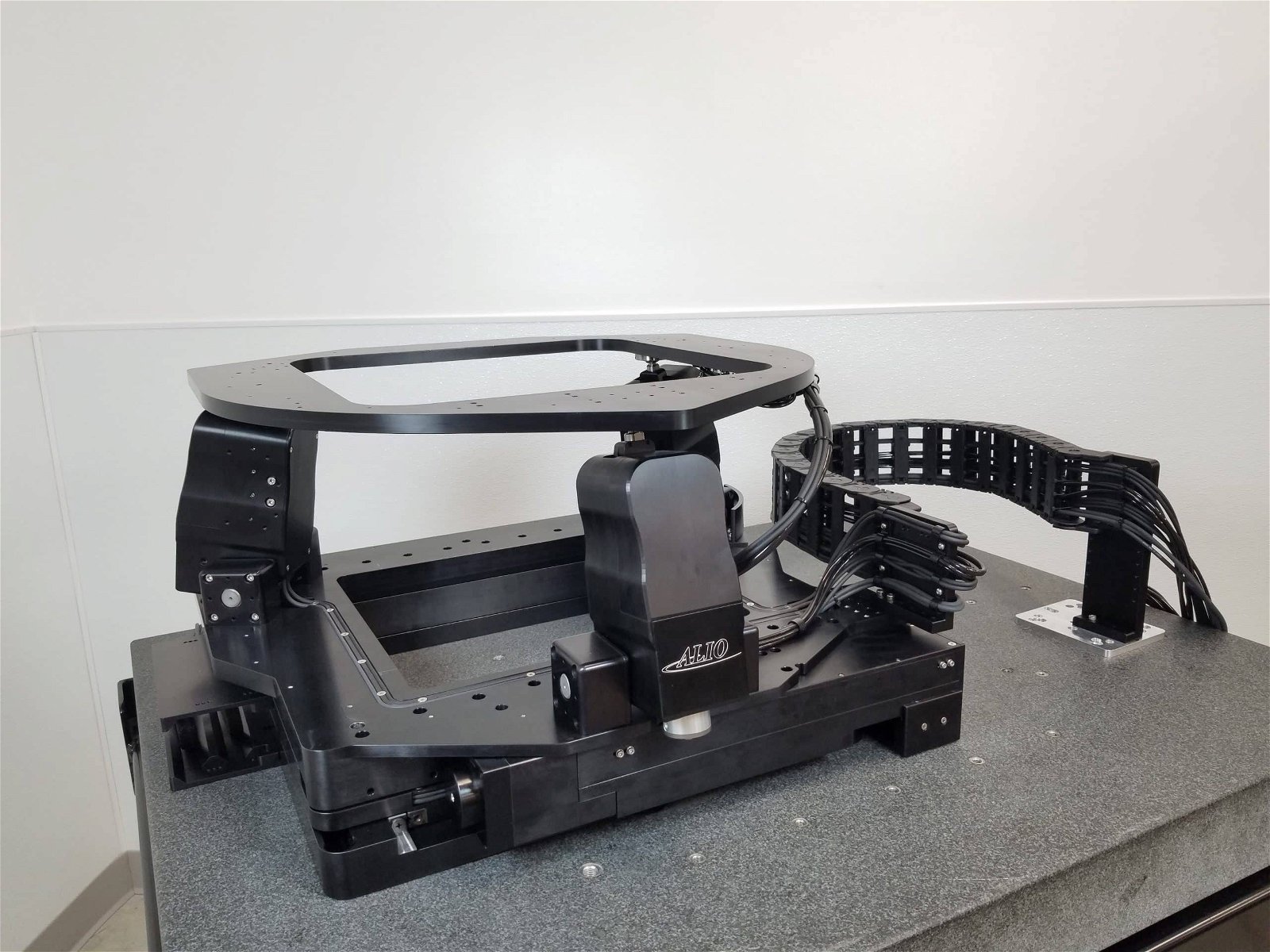

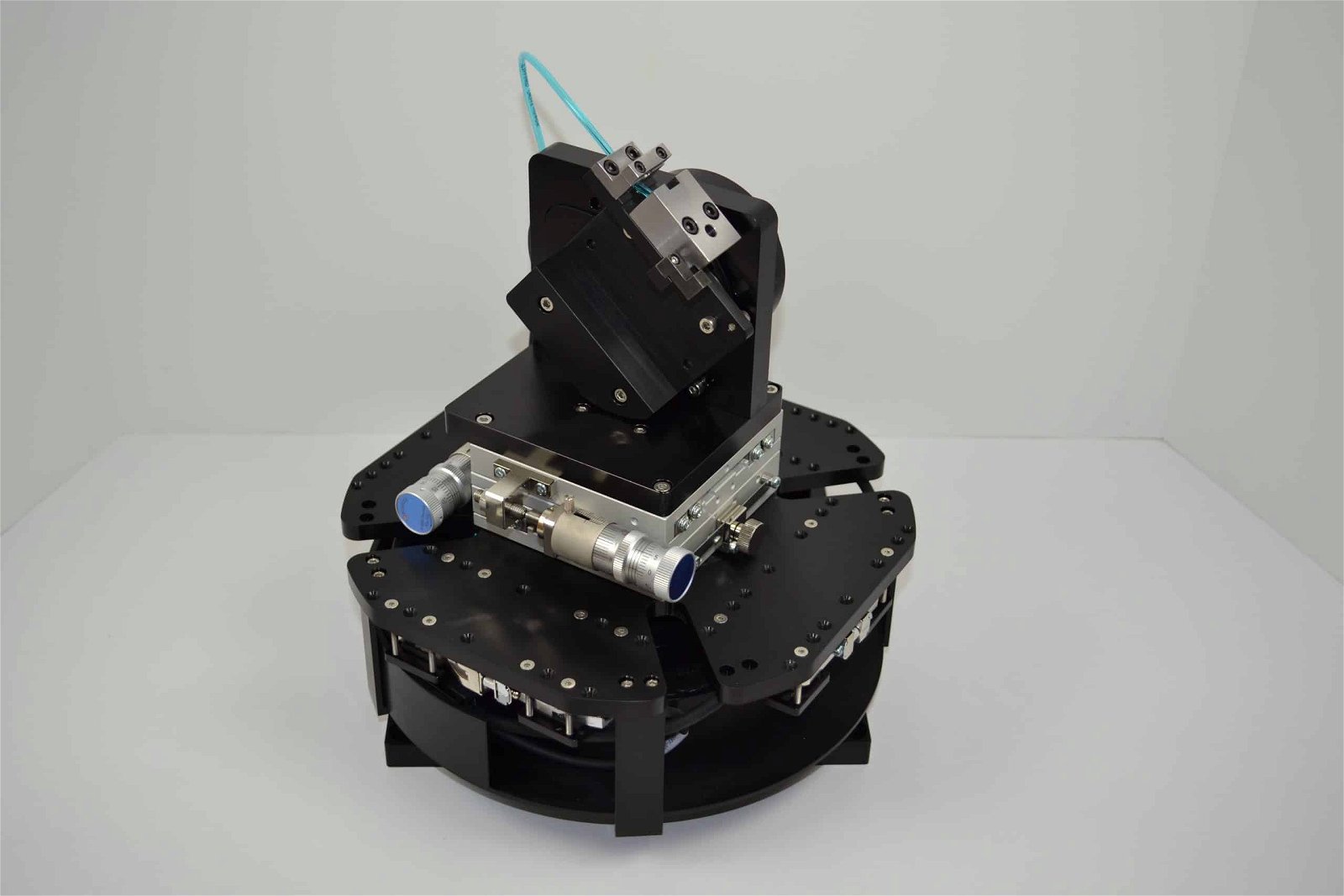

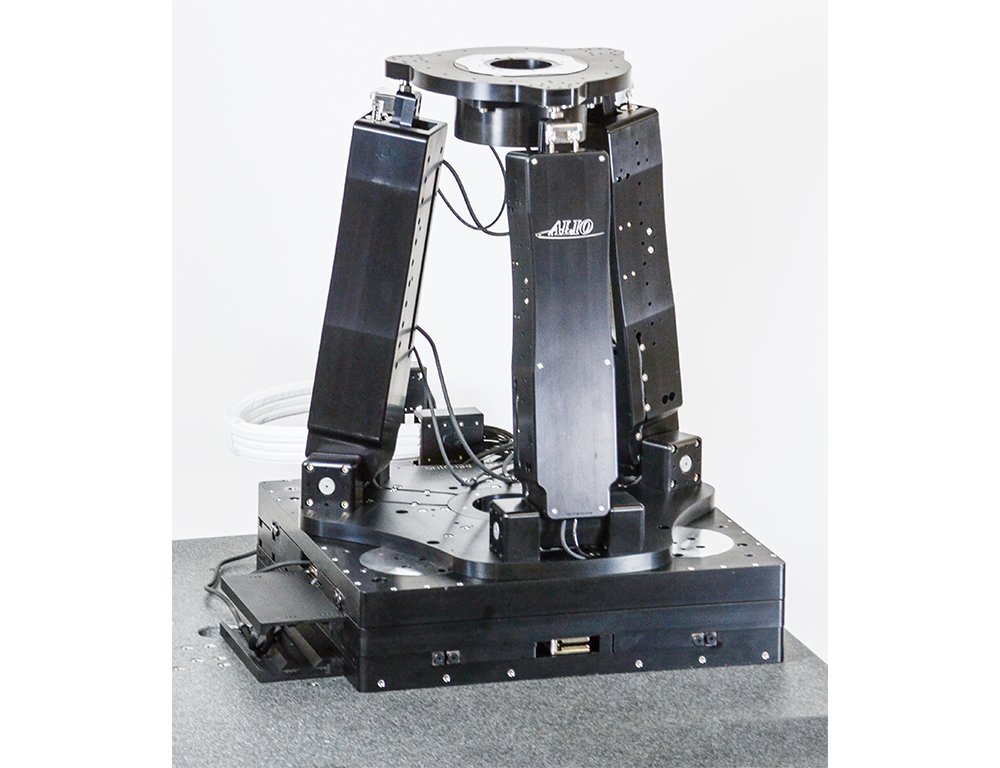

At ALIO Industries, we believe that traditional hexapods will soon become obsolete. That’s why we’ve developed the Hybrid Hexapod®, a patented and revolutionary approach to six-degree-of-freedom (6-DOF) positioning that delivers nanometer-level accuracy at any working point.

Our innovative modular design features a tripod with non-contact linear driven motors and linear encoders, offering any rotary- and Z-motion capabilities on a monolithic XY basis. Unlike traditional hexapods, the Hybrid Hexapod® boasts a unique stiffness, enabling us to avoid common problems associated with screw-driven Stewart platforms, such as pitch errors, backlash, and friction.

With our design, you can move in X or Y with just one axis, tip or tilt with just three legs of the tripod, and rotate around the Z-axis by adding a 360-degree rotary stage in the middle of the tripod. These features, along with many other specific details, make the Hybrid Hexapod® an ideal solution for any application requiring 6-DOF positioning with nanometer/arc-sec levels of incremental motion and repeatability.

If you’re looking for a unique design that can simplify your six-dimensional motion while drastically increasing your working cubic volume, turn to the Hybrid Hexapod® from ALIO Industries. To learn more about our standard configurations and what they can achieve, check out our comprehensive datasheet.

Standard Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)

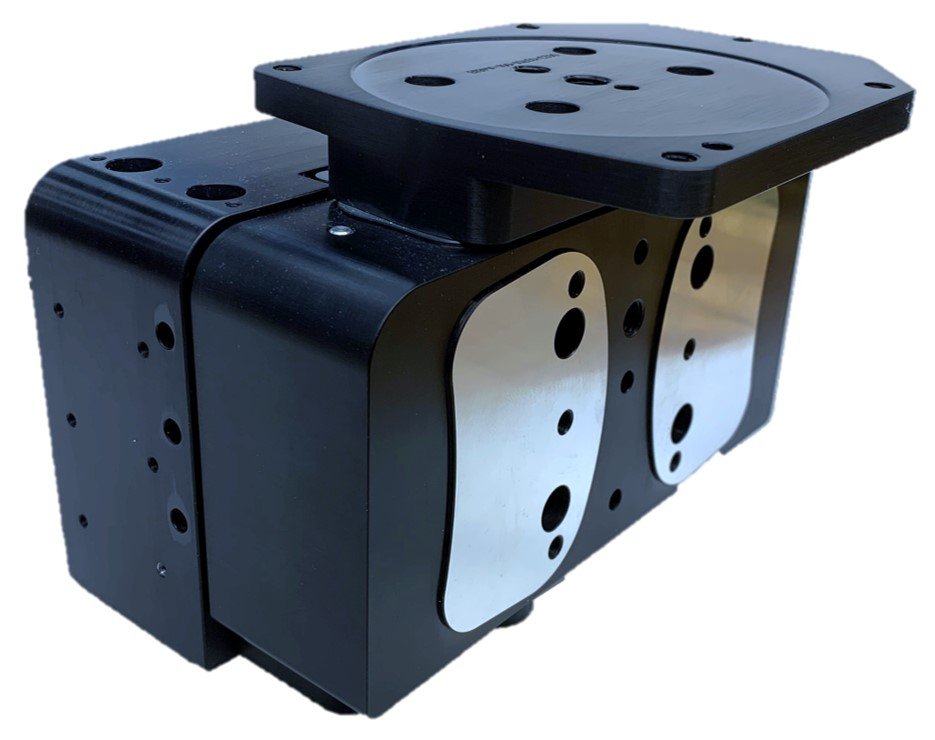

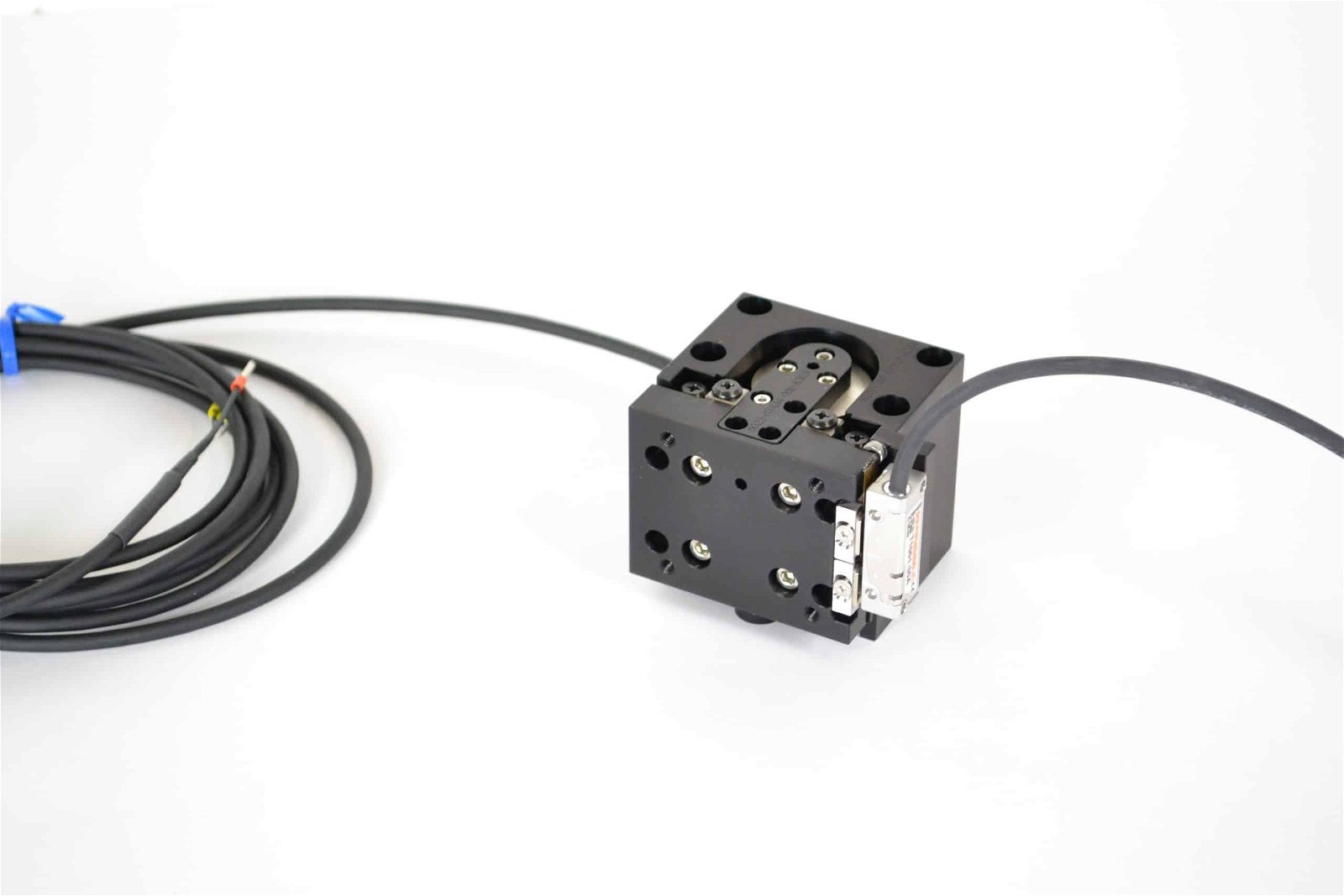

Looking for a compact yet high-performing solution for your six degrees of freedom (6-DOF) positioning needs? Look no further than the MINI Hybrid Hexapod® from ALIO Industries.

Despite its small size, the MINI Hybrid Hexapod® offers an impressive 54,000 mm2 working volume (60x60x15mm) and can be scaled to match your required working volume with options such as brakes, gear reduction, ball screw drive, and linear motor drive. This flexibility makes it an ideal solution for automated lens alignment or bonding processes, camera array modules, translational OIS, telescopic integrated lenses, and miniature camera products like cell phone cameras and drones.

When you need nanometer/arc-sec levels of incremental motion and repeatability, the MINI Hybrid Hexapod® delivers the performance you need with the compact size you want. To learn more about our detailed specifications, download our comprehensive datasheet today. Choose ALIO Industries for your 6-DOF positioning needs with one of our range of robotic hexapod solutions.

Find out more by downloading the detailed specifications:

Miniature Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)RT-(OPTION)

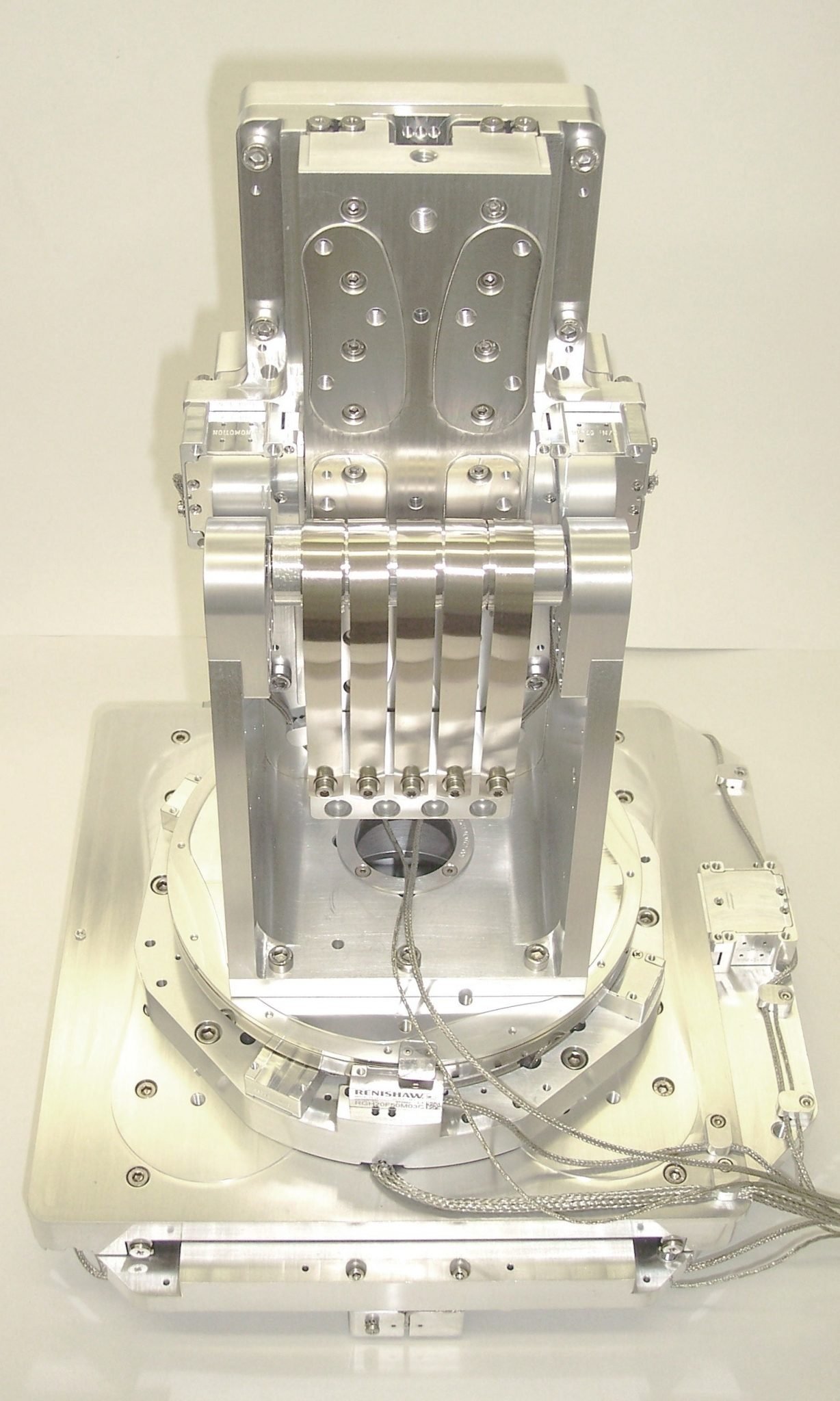

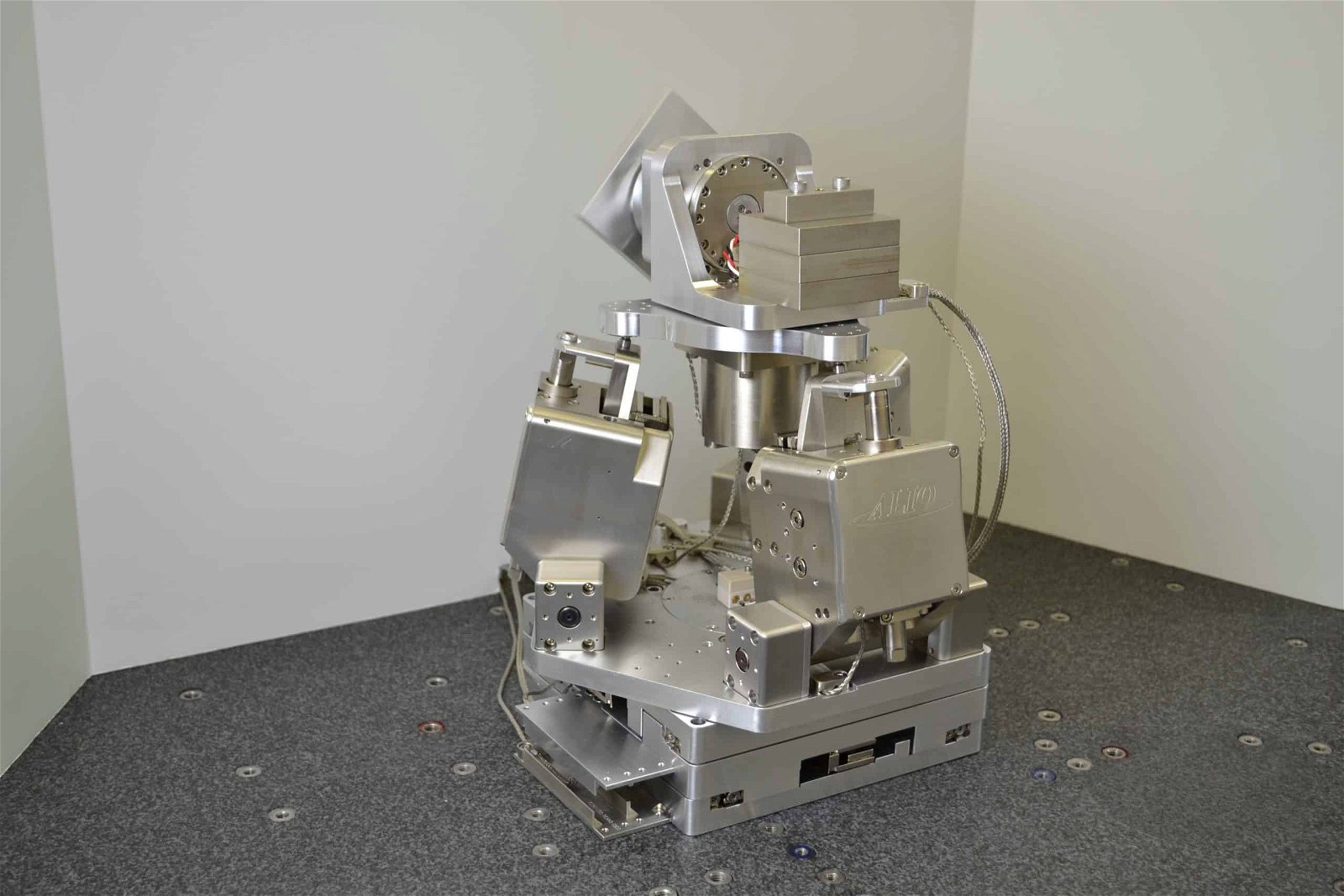

The AngularesTM Hybrid Hexapod® from ALIO Industries offers the widest angular travel range of any 6-Degree-Of-Freedom (6-DOF) positioner on the market, with 60-degree tip/tilt travel. This new hexapod approach features precision crossed roller bearing guides, optical incremental or absolute encoder feedback on all axes, linear motor and/or servo ball screw drives, unlimited programmable tool center point locations, and zero backlash on all axes.

With unlimited XY travel, Z travel of 62 mm (expandable to 208 mm using other tripod models), and continuous 360 degree Theta-Z, the AngularesTM offers unmatched positioning performance. It delivers XYZ bidirectional repeatability of less than +/- 100nm, velocity up to 100 mm/second XY and Z, and less than 10 nanometers linear and 0.1 arc-seconds angular minimum incremental motion.

The AngularesTM is ideal for various applications such as aspheric and freeform optical metrology, silicon photonics packaging and probing, laser micro processing, wafer metrology, camera module alignment and assembly, and optical element and fiber alignment.

Download data sheets to learn more about the AngularesTM Hybrid Hexapod® from ALIO Industries.

AngularesTM – Extra large Tip/Tilt: AI-HH-30D-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R

ALIO’s modular and versatile Hybrid Hexapod® concept allows various adaptions and customization to align with your application requirements. These can range from applications with several dozens of kg load and high force requirements, to totally novel designs with large apertures. Some requirements have been so commonly requested that we decided to standardize them and make them available to all our customers. See specific details below:

High Torque Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)RGR

High Load Hybrid Hexapod: AI-6D-(XY TRAVEL)XY-(R DIAMETER)R-(Z TRAVEL)Z-(OPTION)

Ball Screw Driven Hybrid Hexapod: AI-HH-BSD-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)

Stepper-Motor based Hybrid Hexapod: AI-HH-ST14-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!