At ALIO Industries, we take pride in designing and manufacturing linear motion products that offer unmatched performance and reliability. Our mechanical bearing stages are known for their unrivalled precision, surpassing the precision of air bearing stages that are commonly used throughout the industry. With a focus on 6-D Nano Precision®, we are committed to staying ahead of the curve by designing products that cater to the most exacting applications and cost sensitivities.

Our linear motion system product families are designed to exhibit world-class performance, with component choices based on the demands of the specific application.

At ALIO, we use unique manufacturing techniques and leading-edge components that are tested to NIST traceable nanometer results, ensuring superior performance and unmatched precision. Our products have found applications across a range of industries, including semiconductor, metrology, photonics, and life sciences. When it comes to high-performance and reliable linear motion products, ALIO Industries is the name to trust.

ALIO Industries’ linear X stages are the ideal choice for precision applications, as they are commonly used in the precision industry due to their reliability and performance. The family of stages offers a wide range of travel options from 30mm to 300mm by utilizing two types of linear direct drives: the “LM” and the “CM” series.

The “LM” series provides greater force, higher acceleration, greater speed, and supports payloads of up to 50kg, while the “CM” series offers a low-profile design for tools and applications with space constraints, without compromising precision. ALIO’s linear motion systems and linear X stages are the perfect choice for applications that require precision and reliability.

For more information please download and analyze the following datasheets:

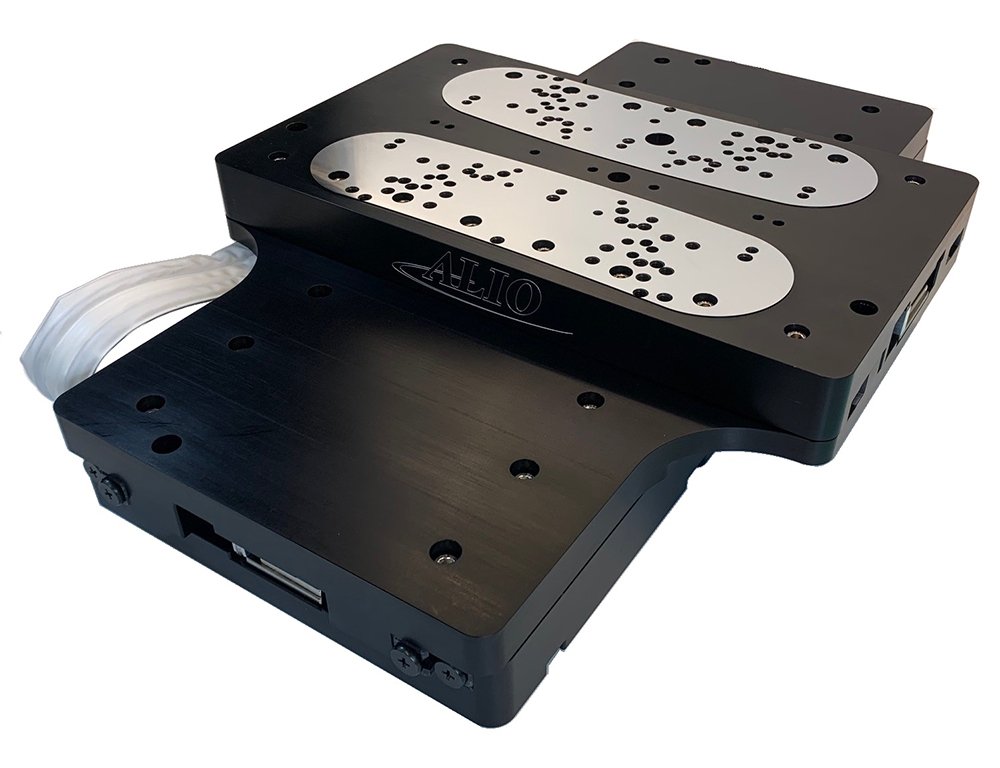

ALIO Industries offers enclosed, monolithic XY stages that are suitable for ultra-precise applications. These stages feature direct linear drives and high-precision crossed roller bearings built into a compact 3-plate system. With nanometer straightness and flatness, as well as optimized orthogonality, the point precision is True Nano®. Standard travel ranges are from 30mm up to 400mm, and stages can be built for high vacuum or clean room applications if needed.

The bi-directional repeatability of these stages is only +/- 30nm, making them suitable for scanning applications requiring a smooth, continuous movement, or for fast step and settle processes when high output is required. The enclosed, monolithic XY stages are available in two series – the standard LM-series and the low-profile CM-series.

For more information, download the datasheets available on our website.

To download datasheets, look for:

ALIO Industries produces open-centered, monolithic XY stages with large apertures for accessibility from all sides. These stages use powerful direct linear drives and high-precision crossed roller bearings in a 3-plate system to achieve outstanding precision. With a bi-directional repeatability of just +/- 50nm, superior straightness and flatness, and optimized orthogonality, ALIO’s open-centered XY stages offer Nano Precision® with travel ranges of 30mm to 400mm. The stages are perfect for scanning applications requiring smooth, continuous movement and fast step and settle processes, and increase throughput substantially. They can be built for high vacuum or clean room applications. ALIO’s open-centered XY stages are available in standard LM-series or the more compact CM-Series. Download datasheets on our website.

Open-Centered Monolithic XY: AI-LM-(TRAVEL)00-(THRU)E-XY

Low-profile Open-Centered Monolithic XY: AI-CM-(TRAVEL)00E-(THRU)-XY

If you need a low-profile solution to avoid space constraints, require different travels in X and Y, and can’t compromise on performance and precision, there are hardly any off-the-shelf products on the market. ALIO’s asymmetrical, monolithic XY stages are unique in the market and can help solve this complex combination of motion requirements.

With linear direct drives, ultra-precise crossed roller bearings, and our 3-plate system, we guarantee highly precise and powerful motion, as well as perfect orthogonality of the X and Y axes in respect to each other.

“Asymmetrical” in this design concept refers to the two different travel ranges of these two stages that are usually achieved by mounting different linear X stages on top of each other.

For further information, contact us or download the following specification sheets:

Asymmetrical, Monolithic XY: AI-LM-(TRAVEL_X)x(TRAVEL_Y)-XY

Asymmetrical, Monolithic XY: AI-SLM-(TRAVEL_X)x(TRAVEL_Y)-XY

ALIO’s precision ball-screw driven X stages are perfect for applications that require precision despite electrical noise. These stages are driven by a torque motor that moves a precision ball screw with an anti-backlash nut, and they can be equipped with pneumatic or electric solenoid brakes if necessary.

Thanks to ALIO’s unique design and manufacturing principles, these stages achieve a bi-directional repeatability of only +/- 100nm, with straightness and flatness well below 5µm (and on request even 1µm can be maintained).

Off-the-shelf versions are available for travels of 30mm, 100mm, 150mm, and 200mm, and can be realized for ambient, high vacuum, and clean room conditions.

For more information on these stages, please refer to the following datasheet:

Linear X with Precision Ball Screw:_AI-VBS-(TRAVEL)00-(BRAKE OPTION)

ALIO has introduced the Micron 2 (µII) motion systems family to compete in the micron-level motion control market. These systems are designed to offer low-cost, mid-precision, reliable, and long-travel stages. As with all ALIO’s products, the Micron 2 (µII) systems are designed with the company’s “quality first” standards, ensuring long-term reliable operation.

The Micron 2 (µII) recirculating ball rail bearing stages come in standard sizes of 100mm up to 2 meters, making them suitable for a wide variety of applications. This family of motion systems is robust and powerful, designed for use either as a stand-alone unit or as a top axis of an integrated solution.

For more details, visit the dedicated Micron 2 (µII) motion systems page.

Find the right stage for your application using our intuitive product configurator.

Get in touch with ALIO: Expert solutions for your precision motion control needs