In high-precision motion systems, specifications like Minimum Step Size are often used to differentiate product capabilities. But dig deeper, and you’ll find that this single metric is frequently misunderstood, and sometimes misrepresented. Why does this matter? Because if you’re selecting or specifying motion systems for critical applications such as semiconductor inspection, photonics alignment, or high-precision metrology, misunderstanding this concept could result in real-world performance falling well short of expectations.

Let’s unpack what Minimum Step Size really means, why it varies depending on measurement location, and how factors like sensor placement, mechanical design, and control strategy influence the result.

LOAD POINT VS. ACTUATION POINT

Most motion control datasheets refer to Minimum Step Size without indicating where it was measured. That’s a major omission. There’s a fundamental difference between the actuation point (where force is applied and feedback is often taken) and the load point (where the actual application-critical work occurs, such as part positioning or laser alignment).

The catch? A system might achieve ultra-fine steps at the actuation point, but that doesn’t guarantee the same performance at the load point, particularly when there’s compliance, backlash, or mechanical offsets in the system.

This raises an essential question. If Minimum Step Size isn’t specified at the point where it actually matters, is it even useful?

UNDERSTANDING THE TERMS

To frame this discussion, let’s clarify a few key concepts:

WHAT INFLUENCES MINIMUM STEP SIZE?

1. Sensor Location

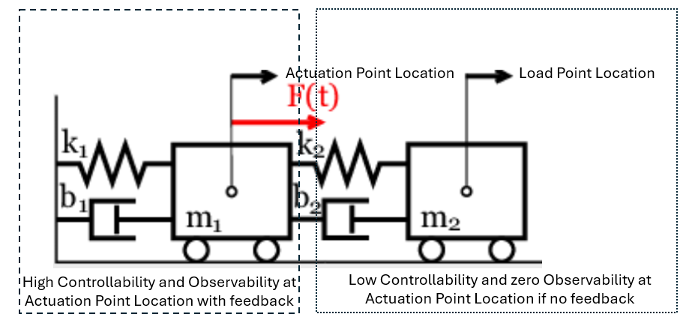

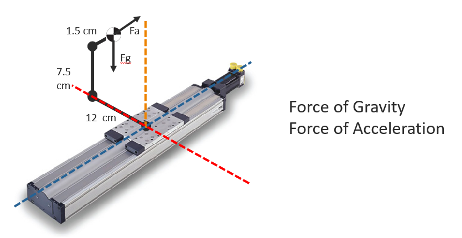

As shown in Figure 1, the placement of the feedback sensor plays a dominant role. Systems with sensors only at the actuation point lack observability at the load point, meaning you can’t measure what the load is actually doing. Even if the controller executes a tiny step, the system can’t confirm whether that step translated to load point motion.

Figure 1.

Designs with sensors at or near the load point offer superior controllability and allow for accurate characterization of Minimum Step Size at the location that truly matters.

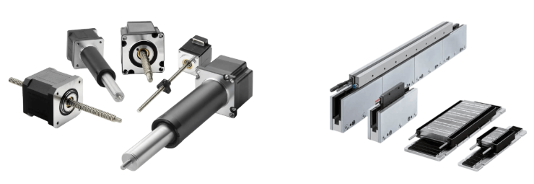

2. Force Delivery Mechanism

Whether your system uses a ball screw or direct drive impacts minimum step size significantly (Figure 2). Ball screws introduce backlash and compliance, particularly problematic during direction changes. In contrast, direct-drive motors eliminate mechanical hysteresis and allow for smoother, smaller, and more repeatable steps.

Figure 2.

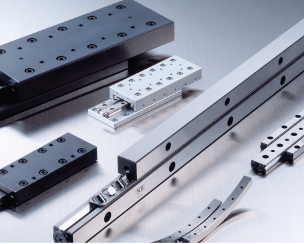

3. Bearing Type and Friction

Bearings aren’t just passive components, they actively influence motion behavior. Figure 3 highlights how air bearings offer minimal stiction and near-frictionless movement, enabling finer and more consistent steps. Mechanical options like cross-roller or truck-and-rail bearings exhibit internal stresses that cause unpredictable behavior, increasing Minimum Step Size at the load point.

Figure 3.

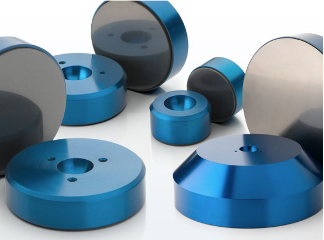

4. Load Point Offset

The greater the distance between the load point and the system’s support structures, the more likely it is that mechanical deflection and Abbe error will degrade step accuracy (Figure 4). These small angular shifts become significant at the nanometer scale.

Figure 4.

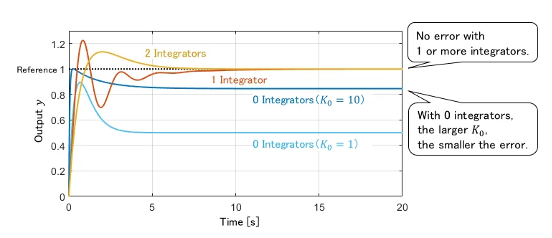

5. Control Strategy

Even the most precise mechanics need a matching control strategy. The presence of an integrator in the loop, which provides zero steady-state error, is key. However, in systems with stiction or backlash, a common workaround is a deadband control algorithm (Figure 5). This intentionally avoids overcorrecting for small errors, but at the cost of sacrificing Minimum Step Size, since no effort is made to move until the error exceeds a threshold.

Figure 5.

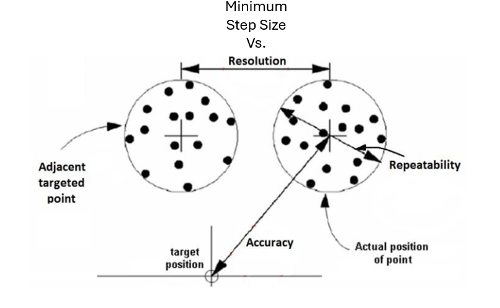

WHEN MINIMUM STEP SIZE BECOMES MARKETING OVER FUNCTION

Here’s a real-world issue. Sometimes, vendors list encoder resolution as the system’s Minimum Step Size. But this is misleading. As Figure 6 shows, repeatability and accuracy are typically an order of magnitude worse than the encoder resolution. So even if your encoder resolves 5 nm, you might only achieve 50 nm repeatability, making the effective Minimum Step Size much larger.

Figure 6.

The takeaway? Resolution is just a piece of the puzzle. Without context (especially repeatability and measurement location) it doesn’t guarantee meaningful performance.

MEASURING MINIMUM STEP SIZE CORRECTLY

To truly understand Minimum Step Size, you need to measure at the load point using high-precision tools like laser interferometers or capacitance probes (Figure 7). These tools help overcome the limitation of embedded encoders by capturing real-world outcomes at the point of use.

Figure 7.

Still, jitter and air disturbances introduce noise into raw measurements, making averaging techniques valuable. As illustrated in Figure 8, filtering data with moving averages can reveal underlying step behavior, but care must be taken. Over-averaging distorts real motion and introduces delays, especially harmful if the same data is used in closed-loop feedback.

Figure 8.

SO WHAT?

Why does any of this matter?

Because whether you’re aligning an optical fiber or positioning a semiconductor wafer, the smallest possible, repeatable motion at the point of interest can define the success of your application. A misunderstanding or misuse of the Minimum Step Size spec can mean overspending on a system that doesn’t deliver, or worse, underperforming in a high-stakes process.

Always ask “where was the Minimum Step Size measured, and under what conditions?” If it’s not at the load point, it may not matter.

If you’d like to understand how to characterize or improve Minimum Step Size in your system, or how your system architecture might be limiting your real-world resolution, get in touch with our team at ALIO. We’re happy to help make “precision” more than just a marketing term.

Click here to read the full white paper – https://alioindustries.com/whitepapers/minimum-step-size/

Get in touch with ALIO: Expert solutions for your precision motion control needs