ALIO Industries offers a range of precision rotary stages that are designed to meet the most demanding applications. Our standard rotary stage family uses crossed roller bearings and frameless torque motors to provide extreme throughput, acceleration, and mass capabilities while maintaining nanometer-level precision. These rotary stages are also highly stiff and can handle offset loads with ease.

Our crossed roller bearing rotary stages have +/-0.2 arc-second repeatability and are rated at 13 to 20 microns of radial and axial run-out. Some models even offer run-outs below 5 microns. We also offer mechanical bearing rotary stages in different sizes to meet varying duty cycles, mass, and acceleration needs, ranging from 80 mm to 300 mm in diameter. For mounting a vacuum chuck, vacuum rotary union options are available on the inner diameter.

Explore ALIO’s range of crossed roller bearing and mechanical bearing rotary stages to find the perfect solution for your rotary motion system needs.

Need more details?

ALIO Industries offers mechanical bearing rotary stages with angular contact bearings to meet the requirements of applications that demand a compact and flat rotary stage with a decent aperture size. With torque motors, these stages enable a smooth continuous movement or a step-and-settle process over the full 360 degrees, without compromising precision or throughput. The stages are highly versatile and suitable for various industries and applications.

To know more about this family of stages, check out the spec sheet.

360 degree Angular Contact Bearing Stages: AI-TM-(DIAMETER)RA

ALIO Industries offers a line of air bearing rotary stages for manufacturers that require the highest rotational precision. These stages move without mechanical contact, resulting in frictionless and wear-free movement. ALIO’s air bearing rotary stages can minimize errors such as wobble, eccentricity, or runout to achieve near-perfect, smooth 360-degree movement even at high speeds or when mounted vertically. Equipped with powerful torque motors, these stages can perform both constant continuous rotation and step-and-settle processes with equal precision and reliability.

It’s no wonder that ALIO’s air bearing rotary stages are commonly used in highly precise applications within the semiconductor, metrology, and photonics industries. For detailed specifications, download the following spec sheets:

ALIO Industries offers industry-leading torque ratings with its two-axis gimbal rotary systems, delivering high rotational speeds without sacrificing precision. The systems can be customized for each customer’s mass, with variable counterbalance, cable guidance, and cable and air feed-through capabilities. The dual-axis rotary systems allow for +/-110 and +/-170 degrees of rotation on the horizontal axis, while exhibiting angular travel +/-180 degrees for rotation about the vertical axis. An air purge is incorporated to protect against contamination and maximize lifespan.

ALIO’s 2-axis gimbal rotary systems have been utilized in a range of industries, including metrology, laser processing, and additive manufacturing. For more detailed specifications, please refer to the spec sheet.

ALIO Industries’ open-center rotary stages utilize tangential linear direct drives with angular contact bearings for up to +/-7.5 degrees of angular movement and an extreme aperture. These stages are ideal for high-precision applications, including the semiconductor, metrology, and life science industries. With rigid bearings and a powerful linear direct motor, they are designed to meet the high-throughput needs of the high-precision market.

Download our product spec sheet for more details.

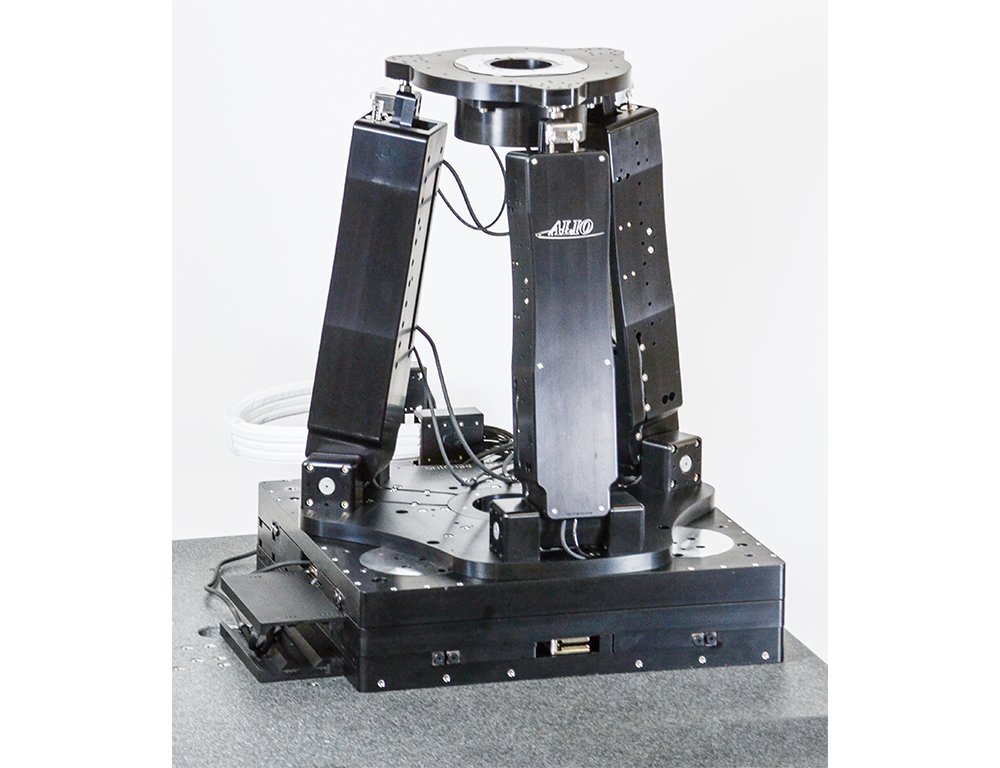

At ALIO Industries, we believe that traditional hexapods will soon become obsolete. That’s why we’ve developed the Hybrid Hexapod®, a patented and revolutionary approach to six-degree-of-freedom (6-DOF) positioning that delivers nanometer-level accuracy at any working point.

Our innovative modular design features a tripod with non-contact linear driven motors and linear encoders, offering any rotary- and Z-motion capabilities on a monolithic XY basis. Unlike traditional hexapods, the Hybrid Hexapod® boasts a unique stiffness, enabling us to avoid common problems associated with screw-driven Stewart platforms, such as pitch errors, backlash, and friction.

With our design, you can move in X or Y with just one axis, tip or tilt with just three legs of the tripod, and rotate around the Z-axis by adding a 360-degree rotary stage in the middle of the tripod. These features, along with many other specific details, make the Hybrid Hexapod® an ideal solution for any application requiring 6-DOF positioning with nanometer/arc-sec levels of incremental motion and repeatability.

If you’re looking for a unique design that can simplify your six-dimensional motion while drastically increasing your working cubic volume, turn to the Hybrid Hexapod® from ALIO Industries. To learn more about our standard configurations and what they can achieve, check out our comprehensive datasheet.

Standard Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)

Looking for a compact yet high-performing solution for your six degrees of freedom (6-DOF) positioning needs? Look no further than the MINI Hybrid Hexapod® from ALIO Industries.

Despite its small size, the MINI Hybrid Hexapod® offers an impressive 54,000 mm2 working volume (60x60x15mm) and can be scaled to match your required working volume with options such as brakes, gear reduction, ball screw drive, and linear motor drive. This flexibility makes it an ideal solution for automated lens alignment or bonding processes, camera array modules, translational OIS, telescopic integrated lenses, and miniature camera products like cell phone cameras and drones.

When you need nanometer/arc-sec levels of incremental motion and repeatability, the MINI Hybrid Hexapod® delivers the performance you need with the compact size you want. To learn more about our detailed specifications, download our comprehensive datasheet today. Choose ALIO Industries for your 6-DOF positioning needs with one of our range of robotic hexapod solutions.

Find out more by downloading the detailed specifications:

Miniature Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)RT-(OPTION)

The AngularesTM Hybrid Hexapod® from ALIO Industries offers the widest angular travel range of any 6-Degree-Of-Freedom (6-DOF) positioner on the market, with 60-degree tip/tilt travel. This new hexapod approach features precision crossed roller bearing guides, optical incremental or absolute encoder feedback on all axes, linear motor and/or servo ball screw drives, unlimited programmable tool center point locations, and zero backlash on all axes.

With unlimited XY travel, Z travel of 62 mm (expandable to 208 mm using other tripod models), and continuous 360 degree Theta-Z, the AngularesTM offers unmatched positioning performance. It delivers XYZ bidirectional repeatability of less than +/- 100nm, velocity up to 100 mm/second XY and Z, and less than 10 nanometers linear and 0.1 arc-seconds angular minimum incremental motion.

The AngularesTM is ideal for various applications such as aspheric and freeform optical metrology, silicon photonics packaging and probing, laser micro processing, wafer metrology, camera module alignment and assembly, and optical element and fiber alignment.

Download data sheets to learn more about the AngularesTM Hybrid Hexapod® from ALIO Industries.

AngularesTM – Extra large Tip/Tilt: AI-HH-30D-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R

ALIO’s modular and versatile Hybrid Hexapod® concept allows various adaptions and customization to align with your application requirements. These can range from applications with several dozens of kg load and high force requirements, to totally novel designs with large apertures. Some requirements have been so commonly requested that we decided to standardize them and make them available to all our customers. See specific details below:

High Torque Hybrid Hexapod: AI-HH-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)RGR

High Load Hybrid Hexapod: AI-6D-(XY TRAVEL)XY-(R DIAMETER)R-(Z TRAVEL)Z-(OPTION)

Ball Screw Driven Hybrid Hexapod: AI-HH-BSD-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)

Stepper-Motor based Hybrid Hexapod: AI-HH-ST14-(XY TRAVEL)XY-(Z TRAVEL)Z-(R DIAMETER)R-(OPTION)