Nanometer-level motion control is increasingly crucial across various industries as they demand tighter tolerances for their technological solutions. This necessity spans sectors like fiber optics, biomedical engineering, micromachines, electronics, semiconductors, energy, optics, aerospace, and synchrotrons.

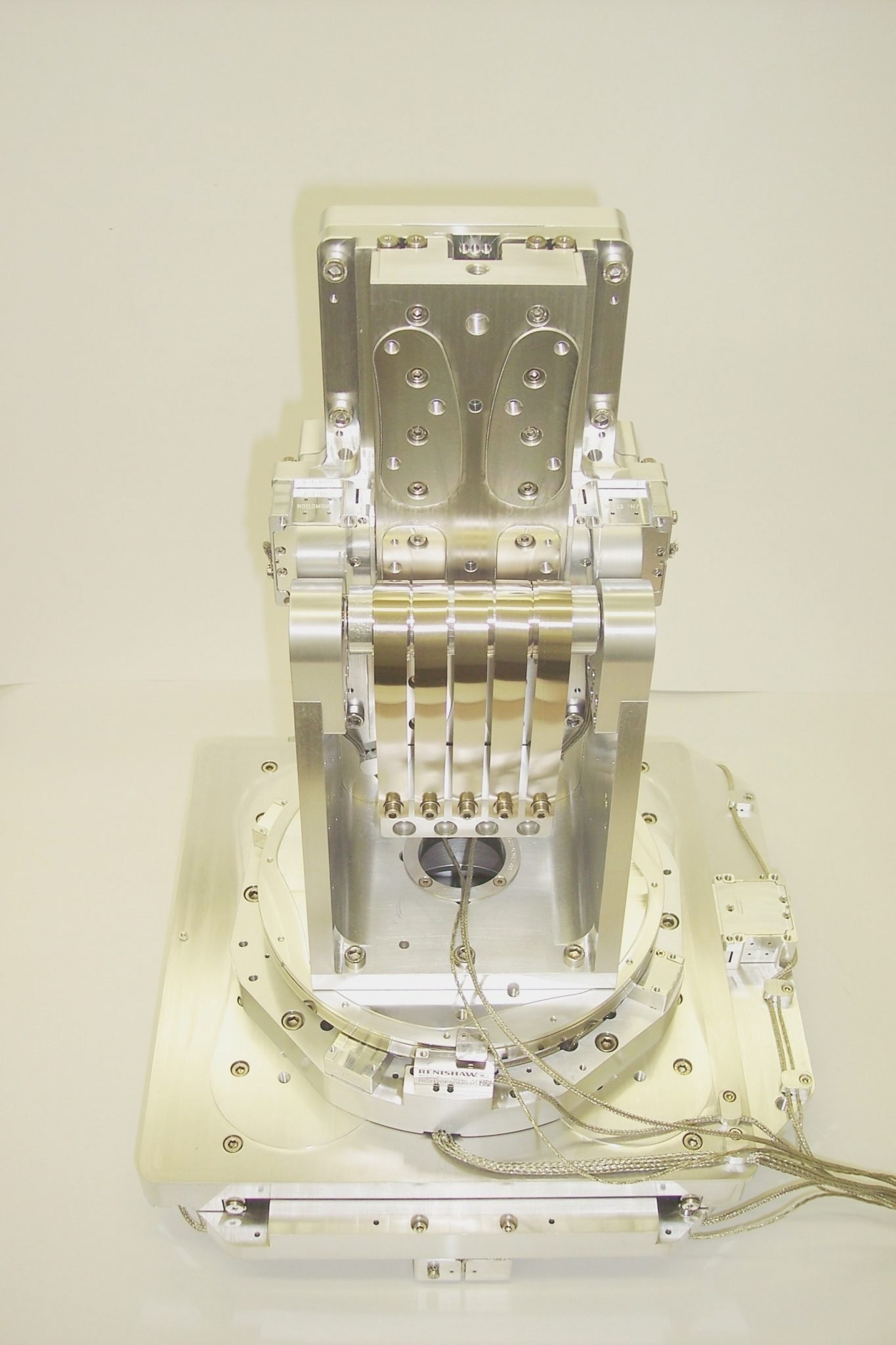

ALIO Industries stands out as a global leader in providing nano-precision vacuum stage and robotic systems. They offer an extensive range of ultra-precise and repeatable motion control solutions, all of which, except their air bearing systems, are compatible with vacuum environments. These include linear, rotary, open center X-Y, hexapods, tripods, and goniometer stages. Available in high vacuum (HV, 10-7 TORR) or ultra-high vacuum (UHV, 10-10 TORR), these systems use materials and components specifically prepared and baked to ensure ultra-low outgassing.

Nano-positioning applications are highly demanding, especially under vacuum conditions or when there is a need for extended travel, higher repeatability, speed, uptime, and lower costs. The design of drive mechanisms, bearings, feedback systems, motion controllers, and the overall kinematic structure is crucial for achieving nanometer precision in both atmospheric and vacuum environments.

Key Design Considerations

Material Selection. The first step in designing a nanometer-level vacuum motion system involves choosing the right materials for the bearings and structure. Typically, vacuum motion systems are made from bare 6061 aluminum or 300/400 series stainless steel. Since precision bearings in vacuum are usually made from 400 stainless steel, using the same material for the motion system is recommended to ensure thermal variations do not affect performance, allowing the bearings to maintain preload.

Precision Bearings:

Suitable mechanical bearings for vacuum applications include recirculating ball rails, linear ball bearings, ceramic linear ball bearings, and crossed roller bearings. ALIO recommends using crossed roller bearings to achieve consistent nanometer-level precision. High-quality bearings, with rollers matched in size, ensure smoother motion, less friction, and minimal straightness deviation.

Position Feedback. Feedback systems in vacuum chambers need special designs to avoid outgassing. ALIO uses optical encoders that read from a tape or glass scale, or directly from a stainless steel ring or a nickel-plated invar spar for higher precision. The invar scale, calibrated using an interferometer, offers near laser precision with excellent repeatability and accuracy, significantly reducing thermal effects.

Drive Mechanism. ALIO employs piezoelectric-driven stages and ceramic linear and rotary servo motors for vacuum motion control. Ceramic servo motors are unique, offering unlimited travel without mechanical hysteresis and maintaining nanometer precision. These motors are robust, with high force and duty cycles, ideal for ultra-high vacuum environments due to minimal outgassing.

Lubrication. The company uses a range of wet to dry vacuum-compatible lubricants, with Krytox being the most common. Krytox works well with mechanical bearings and screw systems but must be applied carefully to avoid causing the bearings to skid and stick. For ultra-high vacuum environments, dry lubricants like Molybdenum Disulfide and Tungsten Disulfide are preferred for their low friction and smooth motion.

Kinematic Structure. For single to four-axis systems, serial kinematics are effective but require precise design and machining to minimize errors. For extreme precision in five or more axes, parallel kinematic solutions are ideal, reducing error quotients and taking up less space. Hexapods with forward and inverse kinematics can enhance motion profiles by minimizing sub-micron errors.

Achieving nanometer precision in motion systems involves meticulously coordinating multiple critical components, especially within a UHV chamber where heat dissipation and outgassing are significant challenges. ALIO Industries invites companies seeking nanometer-level motion control solutions for vacuum applications to collaborate and develop customized, cost-effective systems.

For more information and expert consultation, contact ALIO Industries to explore the possibilities of advanced nano-precision systems.

Get in touch with ALIO: Expert solutions for your precision motion control needs