The world of pathology is undergoing a seismic shift. Traditionally, pathologists have relied on physical glass slides, manually inspecting tissue samples under a microscope — a process that is time-intensive, highly specialized, and geographically limited. However, digital pathology is changing the game. By digitizing tissue samples, pathologists can now capture high-resolution images, analyze them using AI-powered tools, and share them globally in real time.

This transformation is more than just a convenience, it is a necessity. As healthcare systems face rising patient loads and shortages of expert pathologists, digital pathology provides an efficient, scalable, and collaborative solution. It enhances diagnostic accuracy, enables remote consultation, and accelerates research into complex diseases. From early cancer detection to AI-driven histopathology, digital pathology is paving the way for a more data-driven, efficient, and patient-focused healthcare system.

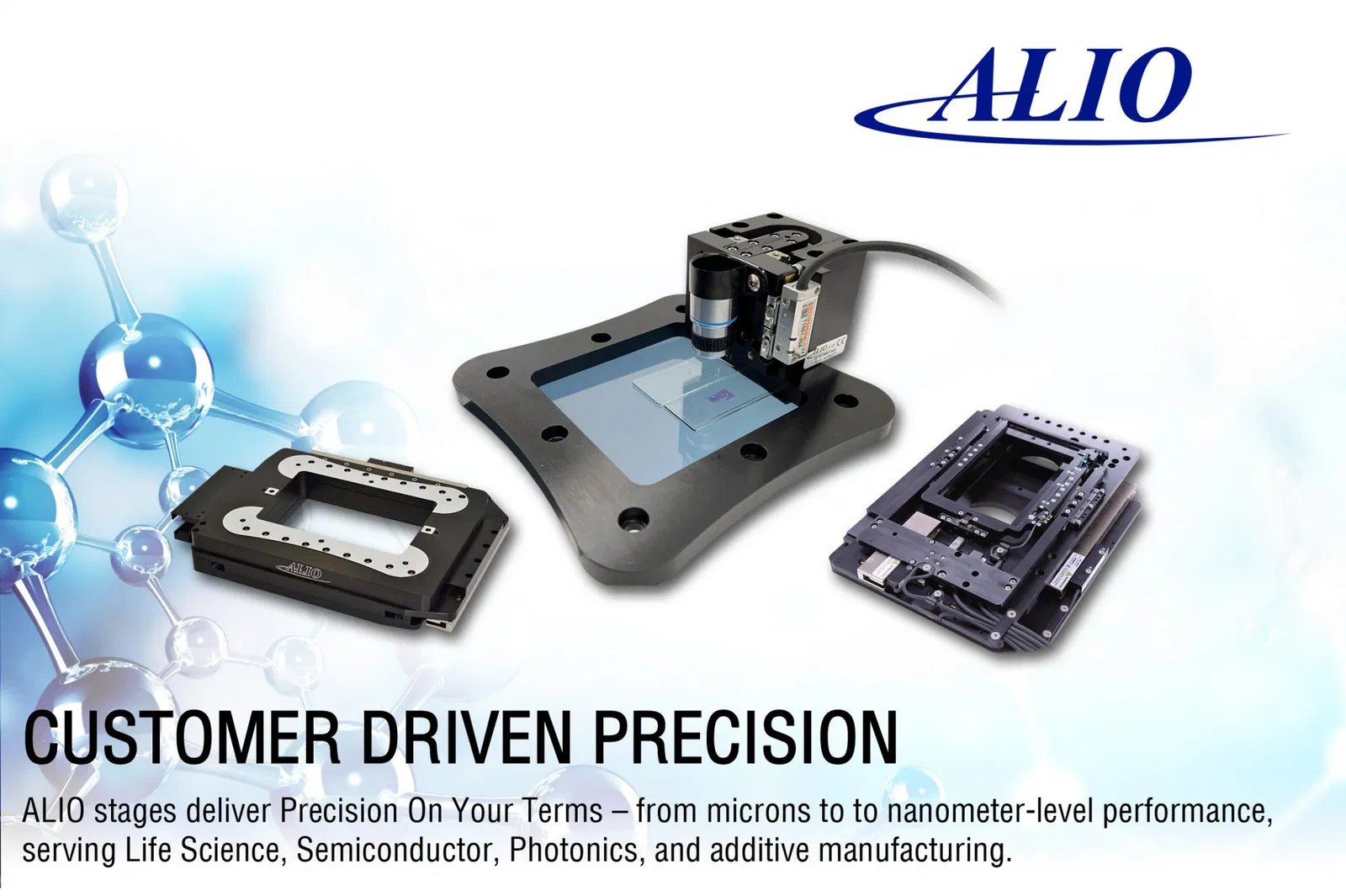

Yet, despite its promise, the technology is only as good as the systems that power it. Achieving precision in specimen positioning, imaging, and automation is essential for ensuring accurate diagnostics and reproducible results. This is where ALIO Industries steps in, providing motion control solutions that deliver unparalleled accuracy, repeatability, and efficiency in digital pathology applications.

THE CRITICAL ROLE OF MOTION CONTROL IN DIGITAL PATHOLOGY

At the heart of every digital pathology system lies a highly complex motion control architecture. Whether it is scanning tissue samples at ultra-high resolutions, moving slides into position with sub-micron precision, or ensuring repeatability in robotic automation, motion control is the backbone of digital pathology imaging systems.

The need for extreme precision in digital pathology cannot be overstated. Imaging and scanning tissue slides require motion systems capable of sub-micron or even nanometer-level accuracy. Any deviation can introduce artifacts or distortions, compromising diagnostic accuracy. Additionally, environmental stability is crucial, as vibrations, electromagnetic interference, and mechanical inconsistencies can all degrade image quality. Motion control solutions must be engineered to mitigate these factors, ensuring the reliability of imaging data. Efficiency also plays a significant role in digital pathology. As labs process thousands of slides daily, motion systems must operate with both speed and precision while integrating seamlessly with AI-powered diagnostic tools and robotic sample handlers.

OVERCOMING CHALLENGES

ALIO Industries is setting new standards in digital pathology with ultra-precise, highly repeatable motion control systems. As an industry leader in precision motion solutions, ALIO designs and manufactures cutting-edge stages, gantries, and robotic systems specifically optimized for digital pathology applications.

High-resolution imaging depends on absolute precision, and ALIO ensures this with innovative motion control technologies that eliminate positioning errors and enable flawless imaging. The combination of ultra-high precision cross-roller bearings and linear encoders provides a level of control that guarantees seamless image stitching, whole-slide scanning, and high-throughput microscopy. Linear encoders play a fundamental role in ensuring accurate slide movement and positioning through real-time positional feedback. ALIO’s cross-roller bearing stages deliver exceptional rigidity and ultra-smooth motion while maintaining precision, making them ideal for the demanding requirements of digital pathology. These mechanical bearing systems are carefully installed, tuned, and tested by ALIO’s expert engineers to meet industry-leading accuracy specifications, ensuring optimal performance in pathology labs where precision is paramount.

Digital pathology systems must also combat vibrations and external interference that threaten imaging accuracy. ALIO’s motion control solutions address this issue by eliminating mechanical disturbances and ensuring a stable platform for flawless imaging. Active feedback and real-time correction mechanisms ensure stability and consistency across all scans by compensating for even the slightest micro-movements.

Automation plays a central role in modern digital pathology workflows, and ALIO’s motion control solutions are designed to integrate seamlessly with robotic sample loaders, AI-driven diagnostic tools, and high-speed slide scanners. If required, ALIO can work with customers to customize robotic slide handling systems which ensure specimens are delicately handled, minimizing the risk of damage or contamination. High-speed sample loading further enhances laboratory efficiency, allowing for rapid and precise scanning processes.

TAILORED PRECISION

At ALIO Industries, precision is more than just a specification — it’s a philosophy. The company’s approach, Customer Drive Precision and Tailored Precision, ensures that every motion control solution is designed to meet the specific requirements of digital pathology applications. Unlike off-the-shelf motion systems, ALIO’s solutions are built to integrate seamlessly into highly specialized pathology instruments, delivering superior performance, longevity, and reliability. Whether optimizing motion dynamics for faster scanning, integrating custom-built actuators for higher precision, or ensuring compatibility with AI-powered analytics, ALIO’s expertise is driving innovation across the digital pathology landscape.

THE FUTURE OF DIGITAL PATHOLOGY

As digital pathology continues to evolve, ALIO Industries remains committed to advancing motion control technology to meet the demands of the future. With nanometer-precise systems designed to support pathology labs, research institutions, and medical technology companies, ALIO is enabling the development of next-generation AI-driven diagnostics, real-time telepathology, and fully automated pathology workflows.

The success of digital pathology hinges on flawless motion, seamless automation, and ultra-precise imaging, and ALIO is at the forefront of delivering these critical capabilities. For pathology OEMs looking to revolutionize their imaging systems, ALIO offers not just motion control solutions but a true partnership in precision. With a commitment to “Your Path to Precision” and “Precision Built for You,” ALIO works closely with digital pathology innovators to shape the future of diagnostics, ensuring faster, more accurate, and more reliable healthcare outcomes.

Get in touch with ALIO: Expert solutions for your precision motion control needs