Bill Hennessey, President, ALIO Industries

Vertical integration is a strategy where a company expands its business operations into different stages along its production path, effectively controlling the key steps from design to marketing a final product. It’s a powerful approach that allows for enhanced quality control, streamlined processes, and greater market dominance.

Vertical integration plays a crucial role in the manufacturing of ultra-precise motion control systems, primarily due to the stringent quality and performance standards these systems must meet. Firstly, vertical integration allows manufacturers to maintain strict control over the quality of each component. In ultra-precise motion control systems, even the smallest imperfections or variations in components can lead to significant deviations in performance. By controlling the entire production process, with design, machining, metrology, manufacturing, and assembly teams all working together under one roof, cross-company collaboration can be nurtured every day. This allows flexiblity and agility in the manufacture of high quality ultra-precise solutions, and ensures that each part meets exacting standards. This level of control is vital for maintaining the reliability and precision these systems require. Furthermore, vertical integration enables manufacturers to implement consistent quality control processes throughout the production cycle, leading to fewer defects and higher reliability.

Vertical integration also enhances the ability of manufacturers to innovate and tailor solutions to specific customer needs. In the field of ultra-precise motion control, customer requirements can be highly specialized, demanding custom solutions. By overseeing every stage of the manufacturing process, companies can more effectively integrate research and development efforts into production. This integration fosters a seamless feedback loop between design, testing, and manufacturing teams, allowing for rapid iteration and improvement of products. Additionally, vertical integration reduces dependence on external suppliers, which can be critical in managing supply chain risks and ensuring timely delivery of products.

PROBLEMS WITHOUT VERTICAL INTEGRATION

When a motion control system manufacturer is not vertically integrated, several problems can arise, significantly impacting the quality and efficiency of production. The most prominent issue is the potential for inconsistencies in component quality. Without direct control over the entire manufacturing process, a company relies on external suppliers for key components and services. This reliance can lead to variations in quality, as different suppliers may have differing standards or use various materials and processes. For ultra-precise motion control systems, where even minor discrepancies in component quality can lead to substantial performance issues, this inconsistency can be detrimental. It can result in increased rates of system failure or the need for more frequent maintenance and recalibration, undermining the reliability and precision of the systems.

Another major challenge faced by non-vertically integrated manufacturers is the potential for supply chain disruptions. Depending on external suppliers exposes manufacturers to risks such as delays, increased lead times, and fluctuating costs, which are beyond their direct control. These disruptions can hinder the manufacturer’s ability to deliver products on time, impacting customer satisfaction and business reputation. Furthermore, the lack of direct control over the supply chain makes it challenging to implement rapid changes or improvements in response to evolving market demands or technological advancements. This situation can stifle innovation, as manufacturers may find it difficult to coordinate and implement new designs or modifications quickly when they are dependent on external entities for critical components. Overall, the absence of vertical integration can lead to reduced agility and competitiveness in the fast-paced and technologically advanced field of motion control systems.

QUESTIONS TO ASK

When customers are seeking a motion control system supplier and wish to ensure that their chosen supplier is truly vertically integrated, they should consider asking a series of detailed questions. These questions can help them ascertain the extent of the supplier’s integration across various stages of the production process, from raw material sourcing to final assembly and after-sales support.

Design and Engineering

In the highly specialized field of ultra-precise motion control system manufacturing, the seamless integration of design and engineering is critical. A robust in-house engineering team, intimately involved with both design and development, is often a hallmark of a supplier’s commitment to excellence and innovation. Their hands-on role in the manufacturing process ensures that the intricate specifications required for such precision instruments are met with meticulous attention to detail.

The constant interaction and feedback between the engineers and the production line are instrumental in facilitating a dynamic environment where design iterations are swiftly translated into tangible products. Moreover, this close collaboration is typically indicative of a deeply integrated supplier, where systematic processes are in place to ensure that engineering breakthroughs are not only conceptualized but also effectively implemented, leading to superior product outcomes and enhanced reliability that align with the complex demands of modern applications. Customers, therefore, should actively seek insights into these collaborative processes, including the regularity of communications, project management tools, and quality assurance methodologies, to gauge the supplier’s capability to deliver cutting-edge, reliable motion control systems in a timely manner.

Quality Control Procedures

When looking at ultra-precise motion control systems, the integrity and reliability of the final product are directly tied to the supplier’s quality control rigor. Customers must examine the depth and breadth of quality assurance protocols that span the entire manufacturing spectrum, ensuring these systems are not just compliant but exemplary in their performance. Detailed queries into a supplier’s specific quality control strategies — including statistical process control, equipment calibration, material traceability, and staff expertise — are fundamental. Additionally, understanding how these measures are documented, audited, and evolved is pivotal to gauging the supplier’s dedication to excellence. The process doesn’t end at manufacturing; it extends to comprehensive testing and a robust corrective action system for any deviations, underscored by adherence to global quality standards like ISO certifications. This comprehensive approach to quality control, from inception to delivery, signifies a supplier’s readiness to meet and surpass the stringent demands of the motion control industry.

Supply Chain Management

Grasping how a supplier manages its supply chain, particularly for components not manufactured in-house, is critical for customers aiming to gauge the supplier’s resilience against external disruptions and risk management acumen. It’s imperative for customers to inquire about the strategies and practices in place to secure a reliable stream of externally sourced components, as this reflects the supplier’s capability to uphold production consistency and quality, ensuring an uninterrupted supply of high-precision motion control systems.

Production Flexibility and Scalability

In the field of manufacturing, particularly for specialized equipment such as ultra-precise motion control systems, a supplier’s ability to adapt to fluctuating demands and design alterations is vital. By questioning a supplier’s agility in modifying production processes and their capacity for scaling operations to match market demands, customers gain valuable insights into the supplier’s operational resilience and flexibility. This adaptability not only speaks to the supplier’s readiness to cater to bespoke customer requirements but also reflects their robustness in the face of volatile market conditions, ensuring continuous supply and service excellence.

Lead Times and Delivery

Evaluating a supplier’s lead times and their approach to delivery schedules is a critical aspect of the supplier selection process, especially in industries reliant on ultra-precise motion control systems where timing can be as critical as the technology itself. A detailed understanding of the supplier’s typical lead times from order placement to delivery, along with their protocols for mitigating and managing unforeseen production or delivery delays, offers a clear picture of their operational efficiency and dependability. This insight is pivotal for customers whose operations hinge on the timely integration of these sophisticated systems, ensuring that the supplier’s time management aligns with their strategic and operational objectives.

Research and Development

Understanding the role of R&D within a supplier’s operations is a vital measure of their capacity for innovation and their commitment to advancing their products. Detailed inquiries into how the R&D team influences product development, along with the mechanisms for translating R&D breakthroughs into production-ready solutions, provide critical insights into the supplier’s ability to stay at the forefront of technology and respond proactively to evolving market demands. This exploration helps to ensure that the supplier is not only current with technological trends but is also actively shaping the future of motion control systems through continuous improvement and innovation.

After-sales Support and Services

In the context of supplying complex ultra-precise motion control systems, the scope and quality of after-sales support services are as critical as the product itself. Probing into the nature and extent of the supplier’s after-sales support, including the availability of technical assistance, maintenance services, and the prompt provision of spare parts, is imperative. These elements are indicative of the supplier’s dedication to customer satisfaction and their understanding of the operational continuity needs of their clients. Reliable after-sales service ensures that any potential issues can be addressed swiftly, minimizing downtime and extending the lifespan of the systems, which in turn reflects the supplier’s commitment to a partnership that extends beyond the initial sale.

Environmental and Ethical Practices

Customers committed to responsible sourcing should thoroughly investigate a supplier’s environmental stewardship and ethical labour practices. Inquiring about the supplier’s strategies for minimizing environmental impact during production and their adherence to ethical labour standards is essential. Such questions not only reflect the customer’s values but are also becoming increasingly significant in a global market that prioritizes sustainability and social responsibility. A supplier’s proactive approach to these issues can be a strong indicator of their overall corporate integrity and the long-term viability of partnering with them, ensuring that the products being sourced are not only technically advanced but also responsibly produced.

SUMMARY

Throughout this artilce, we’ve emphasized the critical role of vertical integration in manufacturing ultra-precise motion control systems, focusing on the necessity of in-house capabilities in design and engineering to ensure precision and innovation. We’ve underscored the importance of stringent quality control measures that span the entire manufacturing process, the management of external supply chains, and the adaptability of production to meet shifting demands.

The significance of thorough R&D practices has been highlighted as a driver of technological advancement, while robust after-sales support and services have been pointed out as key to maintaining system integrity post-purchase. Finally, the imperative of environmental and ethical responsibility in a supplier’s operations has been outlined as crucial for customers with corporate responsibility values. Collectively, these aspects form the backbone of a trustworthy and competent supplier in the high-stakes industry of motion control systems.

ALIO Industries’ ultra-precise motion control systems are indispensable in a variety of health and life science applications due to their unparalleled accuracy, reliability, and repeatability. These systems enable ground-breaking advancements by ensuring meticulous manipulation and positioning, vital for the success of genome sequencing, the manufacture of medical and clinical devices, and digital pathology.

Genome Sequencing. For genome sequencing — where even minor variations in the stage velocity or drift of the trigger clock can cause poor imaging — ALIO is renowned for providing market-leading motion control solutions. The company promotes increased throughput, reduced run time, and lower costs per run coupled with high quality and repeatable imaging by creating a smoother, continuous scan process using a monolithic XY stage and a low friction vertical Z-stage for focusing. Z focusing can compensate for both variation in the sample and the flatness variation of the XY stage. The ideal technology for achieving the optimum move and settle time is a linear motor stage with a magnetic counterbalance. The linear motor allows for maximum acceleration and deceleration and provides exceptional position stability.

Manufacture of Medical and Clinical Devices. Accurate motion control is also crucial in manufacturing medical and clinical devices like diagnostic imaging machines and video endoscopes. For such exacting applications, ALIO provides the AngularesTM Hybrid Hexapod®, which features precision crossed roller bearing guides, optical incremental or absolute encoder feedback on all axes, linear motor and/or servo ball screw drives, unlimited programmable tool center point locations and coordinate offsets, and zero backlash on all axes. This makes the AngularesTM capable of unlimited XY travel, Z travel of 62 mm (which can be increased to 208 mm using other tripod models); tip/tilt travel of 60 degrees (+/- 30 degrees) with continuous 360 degree Theta-Z; XYZ bidirectional repeatability of less than +/- 100nm; velocity up to 100 mm/second XY and Z; and less than 10 nanometers linear and 0.1 arc-seconds angular minimum incremental motion.

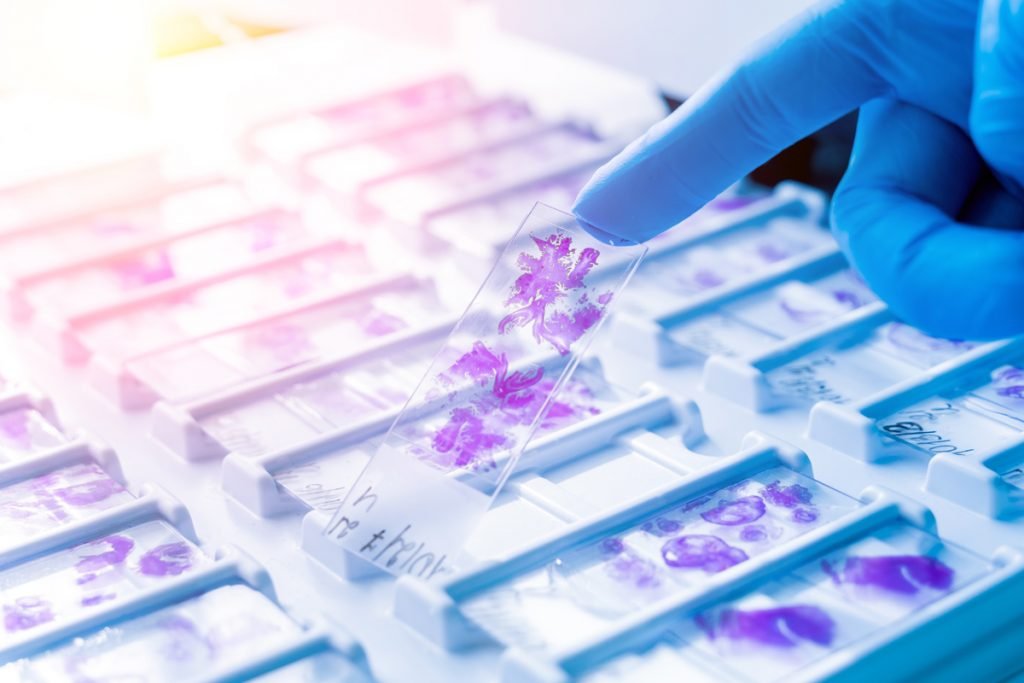

Digital Pathology. ALIO also has a wealth of experience in the area of digital pathology, where the ability to manipulate specimens and imaging devices with unparalleled precision is essential.

Bill Hennessey, President of ALIO says, “ALIO’s motion control systems enable researchers and pathologists to precisely position specimens and imaging components, ensuring accurate and consistent data acquisition. This level of control is particularly critical in applications such as high-resolution scanning, automated sample handling, and image stitching, where sub-micron accuracy is needed. By eliminating motion-induced errors, ALIO’s systems enhance the quality and reliability of digital pathology data, ultimately leading to more accurate diagnoses and accelerating medical research.”

Digital pathology machines demand precise motion control capabilities due to the need for nanometer-level accuracy in specimen scanning and imaging. These systems must precisely position microscope stages and imaging components to ensure that high-resolution images of tissue samples are acquired without motion-induced distortions or artifacts. Any inaccuracies in motion control can compromise the quality of digital slides, potentially leading to misdiagnosis or reduced research validity. Additionally, in automated digital pathology workflows, such as slide loading and sample handling, precise motion control is essential to avoid specimen damage, contamination, or misalignment.

ALIO boasts a range of ultra-precise motion control systems that can cater for even the most demanding digital pathology application.

(6th November 2023 Arvada, CO, USA) As industries accelerate into an era defined by nanoscale perfection and micron-level accuracy, for many applications the spotlight falls on the sophisticated configuration of gantries to include advanced features that allow the next level of precision within machine motion control systems. These configurations, once reserved for niche applications, have become the backbone of countless manufacturing processes. From the delicate assembly of semiconductor chips to the precision-driven world of medical diagnostics, getting the motion just right is not merely about quality — it’s about ensuring operational efficiency, reducing costly errors, and, in some sectors, guaranteeing safety. In this precision-focused age, ALIO Industries is leading the way, and has an innate understanding of such configurations, and knows that mastering them isn’t a luxury; it’s an imperative for manufacturers aiming to lead the vanguard of innovation.

A gantry configuration in ultra-precise motion control systems refers to a framework used to dynamically move over a relatively large area or workspace with incredible accuracy. This structure typically comprises linear axes that allow movement in multiple directions — often in the X, Y, and Z planes. Within the realm of ultra-precision, gantry systems are meticulously designed to minimize vibrations, thermal expansions, and other disturbances, ensuring that movements are consistent to the scale of microns or even nanometers, making them essential for tasks like micro-assembly or semiconductor fabrication. Additional rotational (yaw) motion pertains to movement around a vertical axis.

Beyond this traditional addition of further axes, ALIO offers a “Yaw Compliance” option that can be used on its configurable gantry robots contributing to their superior precision and +/- 1.5µm accuracy. The Yaw Compliance option is a virtual rotary axis allowing precise compensation for small angular misalignments that also may be used as an actual rotary axis for small intended angular motions.

Bill Hennessey, President at ALIO says, “There is a reason that customers engage with ALIO as they strive to innovate new manufacturing processes and products. Engaging with a motion control systems supplier like ALIO with a deep understanding of motion challenges is vital due to the inherent demand for precision and accuracy in many applications. Whether in manufacturing, or R&D, accurate multi-dimensional movement is crucial. A supplier well-versed in gantry configurations ensures the system offers consistent and reliable motion. Without such specialized knowledge, the risk of motion discrepancies increases, potentially compromising the application’s success. Also, every application has unique motion requirements, making it imperative to avoid a generic, one-size-fits-all approach. Suppliers like ALIO with in-depth expertise can tailor the design of the motion control system to suit specific application demands. This tailored approach not only enhances system performance but can also offer cost savings by eliminating unnecessary features or over-specifications. An optimized system design further benefits the end user by improving the system’s durability and reducing its maintenance needs over its lifetime.

The rapidly evolving nature of many industries means that machinery and equipment such as ALIO’s must also adapt and evolve. The company’s robust understanding of sophisticated configuration of gantries makes it better positioned to anticipate and adapt to future challenges and trends. This adaptability ensures the supplied motion control systems remain relevant and can be updated or modified as demands change, maximizing their usable lifespan and providing a more substantial return on investment for the end user.

In ultra-precise applications, the specifications of gantries are meticulously adapted to suit each task’s unique demands. The scale and reach of the gantry can differ significantly, with some applications necessitating compact, intricate setups, while others might require larger but equally precise systems. Meanwhile, yaw control can vary in its granularity and accuracy. The degree and precision of yaw adjustments needed can be influenced by the intricacies of the task at hand. Tailoring these configurations ensures that every application can meet its distinct precision benchmarks, and ALIO’s Yaw Compliance option contributes greatly to the exacting precision that can be achieved.

Hennessey concludes, “Working with a motion control supplier that lacks a comprehensive understanding of gantries and the addition of further motion axes can lead to significant challenges. Such oversight can result in systems that fail to deliver the required precision and accuracy, potentially causing production inconsistencies or product defects. The inefficiencies introduced might slow down production speeds, leading to operational delays and increased costs. Furthermore, improperly configured systems could face premature wear and tear, necessitating frequent maintenance or replacements. In critical applications, these shortcomings not only translate to financial losses but can also pose serious safety risks and jeopardize mission-critical tasks.”

(October 25th 2023, Arvada, CO, USA) Cartesian gantries are robotic and motion control systems that operate within a defined three-dimensional space based on the orthogonal X, Y, and Z axes of the Cartesian coordinate system. Utilizing linear motors, precision bearings and state-of-the-art geometric error compensation techniques these gantries enable precise movement along each axis, allowing for straight-line paths in any direction within the system’s defined workspace.

As industries evolve, there’s a push towards miniaturization, increased product complexity, and higher quality standards. In today’s industrial environment, highly precise Cartesian gantries are crucial due to the ever-increasing demand for accuracy, repeatability, and speed in production and manufacturing processes. Their simplistic and modular design allows for easy scaling, adaptability, and high repeatability, making them a popular choice for ultra-precise motion control.

These precise gantries allow for tight tolerances to be achieved in applications ranging from semiconductor manufacturing, 3D printing, and automated assembly lines, to scientific research equipment and medical devices. Additionally, in an era of automation and Industry 4.0, the integration of these accurate systems facilitates more efficient and flexible production lines, enabling quicker adjustments and responses to market demands. Thus, their importance cannot be understated as they directly contribute to increased productivity, reduced waste, and enhanced product quality, solidifying their role in the competitive industrial landscape.

ALIO Industries’ Cartesian gantries offer large work areas and superior positioning, ideal for a range of pick and place applications. The company’s Cartesian robots are built with precision linear guide rails or air bearings for movement across a horizontal plane, programming is simple, and they are adaptable to limited floor space constraints.

Bill Hennessey, President of ALIO Industry says, “In pick and place applications, the large work areas offered by ALIO’s Cartesian gantries offers a significant advantage by enhancing operational flexibility and efficiency. Such an expansive workspace allows the system to access and manipulate a broader array of components simultaneously, streamlining batch processes and enabling faster production cycles. Moreover, it accommodates the handling of larger products or the simultaneous processing of multiple smaller items, effectively increasing throughput. This spatial flexibility also means that the system can be easily reconfigured or adapted to handle diverse product sizes or types without substantial modifications, catering to the ever-changing demands of modern production lines. In essence, a larger work area not only boosts productivity but also ensures that the gantry remains versatile and adaptable to various pick and place requirements.”

ALIO’s combination of components and motion knowhow is the key to its production of Cartesian gantries that fulfil complex customer requirements. These include high performance motors capable of precision movement even with high payloads and mechanisms that avoid crashes (like having the z stage moving upwards/away from the product instead of falling down in cases of power loss). The structure of the machined parts of such a system must offer outstanding stiffness and be rigid to reduce vibrations and guarantee short settling times (again important for precision and overall throughput improving system efficiency).

Hennessey concludes, “ALIO’s Cartesian gantries are also ingeniously engineered to overcome traditional floor space constraints, ensuring optimal performance even in limited areas. A significant attribute of our design philosophy is modularity and efficient use of space. Furthermore, our commitment to precision ensures that every component and subsystem is optimized for compactness while retaining unparalleled accuracy. This means that even in constrained spaces our Cartesian systems can deliver the expected precision and repeatability. This makes them a preferred choice for industries where floor space is at a premium but high-performance motion control is non-negotiable.”

(October 11th 2023, Arvada, CO, USA) ALIO Industries (a Part of Allient) recognises that in the world of medicine and diagnostics, the immediate relevance of digital pathology is indisputable today. As healthcare systems worldwide face increasing demands and challenges, the need for more accurate and efficient diagnostic tools has never been more pressing.

Digital pathology, which involves the digitisation of tissue samples and the application of advanced imaging and analytical techniques, offers a transformative solution. This technology allows pathologists to remotely examine and analyse specimens with unprecedented precision, speeding up diagnosis and facilitating collaboration among experts across the globe. However, to harness the full potential of digital pathology, ultra-precise motion control systems are imperative, and companies like ALIO Industries are at the forefront of providing these critical components.

Bill Hennessey, President of ALIO Industries says, “Digital pathology applications demand ultra-precise motion control systems for several compelling reasons. First and foremost, the microscopic examination of tissue samples requires movements that are accurate down to the sub-micron level. The slightest deviation in motion can compromise image quality and diagnostic accuracy, making ultra-precision an absolute necessity. ALIO’s motion control systems excel in delivering sub-micron precision and repeatability, ensuring that imaging devices can precisely position and capture microscopic details. Furthermore, in the field of digital pathology, environmental factors like vibration and electromagnetic interference can be detrimental to image quality. Motion systems must, therefore, be designed to minimize these disturbances, guaranteeing the clarity and reliability of the images produced.”

The characteristics of successful motion control systems in digital pathology applications go beyond precision. They must be seamlessly integrated into the compact space and workflows pre-determined by the complex imaging system of the instrument. Moreover, durability is paramount, as these systems need to withstand continuous use in demanding laboratory environments. ALIO Industries not only provide ultra-precise motion control but also prioritise these additional features, ensuring their systems enhance the overall efficiency and reliability of digital pathology solutions.

Partnering with a motion control supplier like ALIO Industries is crucial for companies providing instruments for the digital pathology market. The expertise of specialised motion control suppliers can significantly expedite product development cycles while ensuring the highest level of precision and reliability. By collaborating with suppliers that have a proven track record in delivering accurate and repeatable motion systems, digital pathology OEMs can focus their resources on developing cutting-edge imaging and analysis technologies, confident that the critical motion control aspect is in capable hands. This collaborative approach is pivotal in driving innovation and advancing the field of digital pathology, ultimately benefiting patients, clinicians, and researchers by providing faster, more accurate, and reliable diagnostic tools for today’s healthcare challenges.

Hennessey concludes, “In digital pathology applications, achieving precise motion control often entails the utilization of advanced motorized platforms, which are equipped with either linear encoders or piezoelectric actuators. Linear encoders play a pivotal role by providing real-time feedback on position, ensuring the exact movement of specimens and slides. Meanwhile, piezoelectric actuators excel in offering exceptionally fine control, particularly when it comes to focusing and scanning tasks. Additionally, air-bearing stages find widespread use to minimize both friction and vibrations, which are critical factors for maintaining high-quality imaging standards. To further streamline the automation process, motion control solutions in the realm of digital pathology may incorporate robotic arms or loaders for the delicate handling of samples. ALIO’s robotic systems are meticulously engineered to handle specimens and slides with care, minimizing the potential risks of damage or contamination. Furthermore, these comprehensive solutions often seamlessly integrate with imaging devices and software, enabling efficient coordination and facilitating rapid scanning and image acquisition.”

As a proud member of the Digital Pathology Association, ALIO will be present during this year’s Pathology Visions in Orlando, FL from October 29th to October 31st. The company welcomes all attendees to come and discuss any digital pathology applications.

Digital pathology is in the news again today as it continues to drive diagnostic accuracy and facilitates global collaboration among pathologists, ultimately enhancing patient care and advancing medical research as it allows for the digitization of tissue samples. It does this by making it easier to store, share, and analyse medical data remotely. Additionally, it addresses the challenges of workforce shortages and provides opportunities for implementing artificial intelligence algorithms for more efficient and precise disease detection and classification. ALIO Industries is central to innovation in the digital pathology field providing an array of ultra-precise motion control systems that allow companies to continually innovate in this dynamic field.

Ultra-precise motion control systems are pivotal in digital pathology applications, where nanometer-level accuracy is essential for precise specimen manipulation and high-resolution imaging. This accuracy reduces motion-induced artifacts, resulting in higher-quality images critical for accurate diagnosis. Moreover, ultra-precise motion control systems support automation, streamlining workflows, and improving efficiency in digital pathology labs.

Bill Hennessey, President of ALIO Industries says, “Digital pathology machines demand precise motion control capabilities due to the need for nanometer-level accuracy in specimen scanning and imaging. These systems must precisely position microscope stages and imaging components to ensure that high-resolution images of tissue samples are acquired without motion-induced distortions or artifacts. Any inaccuracies in motion control can compromise the quality of digital slides, potentially leading to misdiagnosis or reduced research validity. Additionally, in automated digital pathology workflows, such as slide loading and sample handling, precise motion control is essential to avoid specimen damage, contamination, or misalignment.”

The integration of artificial intelligence (AI) algorithms in digital pathology applications relies heavily on precise motion control. The systems must accurately navigate the specimen slide to capture multiple fields of view for analysis, ensuring consistent and repeatable image acquisition. To achieve these requirements, motion control systems should provide real-time feedback and correction mechanisms to compensate for any deviations, maintain stability, and enable rapid, high-throughput scanning. In essence, the precise motion control demands of digital pathology machines are paramount in achieving accurate diagnoses, reliable research outcomes, and the successful implementation of AI-driven pathology workflows.

Hennessey continues, “Motion control solutions in digital pathology applications often involve advanced motorized stages equipped with linear encoders or piezoelectric actuators. Linear encoders provide real-time position feedback, ensuring precise specimen and slide movement, while piezoelectric actuators offer extremely fine control for focusing and scanning. Additionally, air-bearing stages are commonly used to minimize friction and vibration, crucial for high-quality imaging. To facilitate automation, motion control solutions in digital pathology may include robotic arms or loaders for sample handling. These robotic systems are designed to handle specimens and slides delicately, minimizing the risk of damage or contamination. Moreover, these solutions often integrate with imaging devices and software for seamless coordination, enabling rapid, efficient scanning, and image acquisition.”

Overall, motion control solutions in digital pathology such as those supplied by ALIO Industries to leading OEMs across the world are engineered to meet the demanding requirements of specimen manipulation and imaging, ensuring precise and consistent results critical for accurate diagnoses and efficient research.

Additive manufacturing is disrupting the manufacturing paradigm by fundamentally altering the traditional subtractive process of material removal. Instead of cutting, drilling, molding or machining raw materials, additive manufacturing builds objects layer by layer, directly from digital designs. This approach reduces waste, allows for complex geometries impossible with traditional methods, accelerates prototyping, and customizes production, revolutionizing industries by enabling rapid, efficient, and on-demand creation of intricate parts and products.

As additive manufacturing evolves into a production technology, precision and repeatability become increasingly crucial factors. In prototyping, minor deviations might be acceptable, but in production, consistency and accuracy are paramount. Precise layer-by-layer material deposition ensures that complex geometries are faithfully reproduced, meeting stringent design specifications. Moreover, as industries like aerospace, medical devices, and automotive rely on additive manufacturing for end-use parts, components must meet tight tolerances to ensure safety, performance, and compatibility within larger systems.

Repeatability guarantees that each part manufactured is virtually indistinguishable from the next, essential for assembly line integration and quality control. This consistency minimizes errors, reduces waste, and streamlines production processes. As additive manufacturing gains traction in fields with high-volume manufacturing demands, such as consumer goods and electronics, the ability to consistently replicate intricate and intricate structures amplifies the technology’s viability as a reliable alternative to traditional manufacturing methods.

THE ROLE OF MOTION CONTROL

Ultra-precise motion control systems are integral components within additive manufacturing machines, playing a critical role in achieving the high levels of precision required for producing complex and functional end-use parts. These systems govern the movement of print heads, build platforms, and other critical components with microscopic accuracy, ensuring that material deposition is exact and consistent across each layer of the printed object. By tightly controlling movements and positions, these systems minimize deviations and errors that could compromise the final product’s quality.

In additive manufacturing, precision is essential to create intricate structures, maintain fine tolerances, and achieve optimal surface finishes. Ultra-precise motion control systems contribute to precision by facilitating intricate adjustments, enabling rapid changes in direction and speed, and dynamically responding to real-time feedback from sensors. These systems eliminate the potential for vibrations, oscillations, or jitters that might degrade print quality. Furthermore, they enable additive manufacturing machines to compensate for variations in material properties, environmental conditions, and other factors that could impact the outcome of the printing process.

The seamless coordination of ultra-precise motion control systems with other critical components, such as advanced sensors and real-time monitoring, ensures that each layer of material is deposited with exceptional precision, resulting in complex geometries, functional prototypes, and end-use parts that meet the stringent requirements of industries embracing additive manufacturing for production purposes.

THE MOTION CONTROL RELATIONSHIP

An additive manufacturing machine manufacturer relies heavily on their motion control technology supplier to deliver a range of critical components and capabilities. First and foremost, precision is paramount. The supplier must offer motion control systems capable of nanometer-level precision to ensure that intricate layers of material are deposited with impeccable precision, allowing the creation of complex geometries and intricate details that meet exacting design specifications. This precision guarantees the production of high-quality end-use parts.

Additionally, repeatability is essential for consistent results in additive manufacturing. The motion control technology should provide exceptional repeatability, enabling the production of identical parts across different manufacturing runs. This consistency is crucial for industries like aerospace and medical devices, where quality assurance and regulatory compliance are of highest importance. The supplier must also offer advanced closed-loop feedback systems, integrating sensors and real-time monitoring to ensure that any deviations or errors are promptly detected and corrected during the printing process.

Furthermore, adaptability and scalability are key considerations. The additive manufacturing industry is rapidly evolving, with machines becoming larger, faster, and more sophisticated. The motion control technology supplier must offer solutions that can accommodate various machine sizes and types, seamlessly integrating with evolving printer architectures. This adaptability is essential as manufacturers seek to optimize productivity, reduce downtime, and accommodate new materials and processes. Lastly, collaboration and support are critical aspects. A reliable supplier should offer comprehensive technical support, training, and a partnership mindset, enabling manufacturers to optimize the integration of motion control systems into their additive manufacturing machines, ultimately contributing to the success of their products in the market.

MOTION CONTROL – THE SPECIFICS

Additive manufacturing machines typically employ a combination of linear stages, gantries, rotary stages, and multi-axis systems to control the positioning of print heads, build platforms, and other critical elements.

Linear Stages. High-precision linear stages are a critical component in additive manufacturing machines, facilitating controlled and precise movement along straight paths. These stages employ advanced technologies such as precision linear bearings, ball screws, and linear direct drives to ensure smooth and accurate translation of print heads or build platforms. By maintaining tight tolerances, these stages guide the deposition process with exceptional precision, allowing for consistent layer-by-layer material placement.

In additive manufacturing, accurate layer deposition is vital to achieving the desired object’s geometry and structural integrity. High-precision linear stages play a pivotal role in ensuring that each layer of material is positioned accurately based on the digital design. This level of control minimizes deviations and errors, resulting in printed parts that match the intended specifications. Whether it’s the intricate details of a complex model or the precise alignment of critical features, the capability of high-precision linear stages to enable controlled movement along straight paths significantly contributes to the reliability and quality of additive manufacturing processes.

Gantries. Gantries achieve highly accurate and controlled movements in industrial applications such as additive manufacturing. They serve the critical role of precisely positioning various components, such as print heads, build platforms, or other tools, in a coordinated manner during manufacturing processes. By executing intricate motion paths with minimal deviations, gantries ensures that the deposition of materials or the manipulation of objects follows predetermined trajectories with micron- or sub-micron level precision. This level of control contributes to producing complex and accurate 3D-printed objects, enhancing product quality, dimensional accuracy, and overall manufacturing efficiency.

Rotary Stages. A rotational correction is a common feature within additive manufacturing machines. These stages are designed to rotate objects or components with exceptional accuracy, making them well-suited for applications like continuous 360-degree printing, where cylindrical objects or structures require uniform coverage. Rotary stages allow the print head or material deposition mechanism to apply material around the entire circumference of the object, ensuring even distribution of material and consistent layer deposition.

Furthermore, rotary stages enable precise angular adjustments in additive manufacturing processes. Objects with intricate geometries, overhangs, or complex contours often necessitate controlled rotation to enable the deposition of material at specific angles. Rotary stages provide the necessary flexibility to position the object accurately, allowing the material to be deposited in alignment with the intended design, resulting in high-quality prints with intricate features and precise details. The versatility of rotary stages in enabling both continuous rotation and precise angular adjustments significantly enhances the capabilities of additive manufacturing machines, enabling the production of a wide range of complex parts and components.

Multi-Axis Systems. Multi-axis systems play a pivotal role in enabling complex and intricate movements. These systems involve multiple coordinated axes of motion, allowing for simultaneous control of translation, rotation, and even tilting of components. Multi-axis configurations are particularly important for producing objects with overhangs, undercuts, and complex geometries, as they provide the necessary flexibility to deposit material at various angles and orientations. These systems are crucial in ensuring that the printed structures maintain their integrity and quality throughout the printing process.

Closed Loop Feedback. Closed-loop feedback mechanisms are integral to motion control systems in additive manufacturing machines. These systems incorporate sensors, encoders, and real-time monitoring to continuously measure and correct deviations from the desired positions. By providing immediate feedback to the control system, closed-loop systems minimize errors and inaccuracies, ensuring that the printed objects adhere to precise design specifications. As the additive manufacturing industry advances, motion control systems continue to evolve, integrating advanced technologies such as predictive algorithms, machine learning, and adaptive control strategies to further enhance precision, speed, and overall performance during the printing process.

SUMMARY

Additive manufacturing applications demand ultra-precise motion control solutions like those offered by ALIO Industries due to the intricate layer-by-layer deposition process, necessitating nanometer-level accuracy to ensure high-quality and repeatable results. Moreover, partnership and customization of motion systems are essential for innovating next-generation additive manufacturing machines that push the boundaries of speed, accuracy, and versatility. Collaborative efforts between manufacturers and motion control suppliers enable the integration of tailored solutions, addressing unique challenges and unlocking novel capabilities in 3D printing, ultimately driving the future of the industry and enabling breakthroughs in various sectors.

(29th August 2023, Arvada, CO, USA) ALIO Industries — leading nanometer-level motion control system innovator — is well known for having developed mechanical bearing linear motion systems that can perform at levels that alternative “air” bearing stages struggle to attain. This is down to the company’s focus on 6-D Nano Precision®.

The newly published standard developed by the AMSE (B5.64 standard “Methods for the Performance Evaluation of Single Axis Linear Positioning Systems) seems to finally accept that to accurately characterize the repeatability of such high-end motion systems, a systematic process must be used to characterize the point repeatability of a stage along the entire axis, something ALIO has been advocating for over a decade.

Precision linear motion systems provide highly accurate linear motion along x, y or z axes. They typically consist of a linear guide rail, a carriage or slider, and a drive system. The guide rail provides support and guidance for the carriage, while the drive system creates the force necessary to move the carriage along the rail.

By adding precision ingredients like high resolution encoders, state-of-the-art machining, nano-precise metrology and tuning procedures, these systems can be used in a variety of applications where high accuracy and smooth operation are required, such as in semiconductor manufacturing, precision machining, and optical inspection.

Bill Hennessey, President of ALIO Industries says, “Because of the exacting nature of the applications where linear motion systems are used, it is vital that they can achieve ultra-high levels of repeatable accuracy. This is why ALIO’s linear motion products have been designed and manufactured to have no equal in terms of performance and reliability. The ‘6-D’ in 6-D Nano Precision® refers to the 6 dimensions of motion; linear, straightness, flatness, pitch, yaw and roll. Nano Precision refers to documented proof of performance at or below the +/- 450 nm level. 6-D Nano Precision® means the documented proof of performance over all 6 degrees of freedom of a body in motion at the nanometer level of precision. We are delighted that the new ASME standard recognises the importance of this approach, and it helps differentiate our linear motion systems from those designed and built to the 2-D world of planar repeatability and accuracy.”

All motion systems operate in 3-dimensional space and have errors in 6 degrees of freedom (6-DOF). However, motion systems are often only characterized by performance data of a single or subset of these 6-DOF. This practice leaves several error sources unaccounted for in performance data and specifications. ALIO contends that repeatability performance for metrology inspection and manufacturing systems must be analyzed and specified using a “point repeatability” method that accounts for 6D spatial errors in order to provide true representation of nanometer-precision performance. The ASME B5.64 standard for motion metrology shows that today standards organisations also see its importance.

Hennessey concludes, “The increasing precision of linear motion systems in particular and all motion systems in general requires a new language which transcends the use of terms like ‘precision’ and ‘resolution’ without any degree of qualification. ALIO’s use of Point Precision® and 6-D Nano Precision, and now the newly published ASME standard, redefine the way precision motion systems are measured. All such initiatives or activities in this area are ultimately of enormous benefit for end-users who should be able to specify solutions that can truly achieve what they need in respect of precision and repeatability. ALIO does not build legacy products and is acutely aware of the 6-dimensional errors associated with simple linear motion. As such, we design and manufacture our linear motion stages with these issues in sharp focus with unique manufacturing techniques and leading-edge components tested to NIST traceable nano results.”

All of ALIO’s linear stage product families exhibit world class performance, component choice being dictated by the demands of exacting applications and cost sensitivity.

(Arvada, CO, USA, 15th August 2023) ALIO Industries – an Allient Company — acknowledges the publication of the ASME B5.64 standard “Methods for the Performance Evaluation of Single Axis Linear Positioning Systems” last week as a significant step in the redefinition of measurement of precision in motion systems, something that as a company ALIO has been championing for over a decade.

The ASME standard suggests that when it comes to defining the precision of ultra-precise single axis linear motion systems such as those produced by ALIO, companies should move away from conventional planar methodologies, and towards 6D point precision specifications.

Bill Hennessey, President of ALIO picks up the story, “When analyzing motion control solutions that provide sub-micron and nanometer-level accuracy, ALIO has contended for a number of years that a new language is necessary, and new standards are required to indicate the real levels of precision that different motion control solutions can achieve. So saying, nearly 12 years ago, ALIO trademarked the phrases Point Precision® and 6D Point Precision® to protect its position in the market.

All motion systems operate in 3-dimensional space and have errors in 6 degrees of freedom (6-DOF). However, motion systems are often only characterized by performance data of a single or subset of these 6-DOF. This practice leaves several error sources unaccounted for in performance data and specifications. ALIO has contended for a considerable amount of time that repeatability performance for metrology inspection and manufacturing systems must be analyzed and specified using a “point repeatability” method that accounts for 6D spatial errors in order to provide true representation of nanometer-precision performance. The recent publication of ASME B5.64 shows that standards agencies also see the value behind this methodology.

Historically, specifying repeatability as a single number representing the variation in linear displacement along an axis of travel, i.e. plane repeatability was valid as the repeatability specifications were large enough that other error factors were only a small percentage of the total error and could be ignored. However, this test method makes a critical assumption, namely that the plane only moves in one dimension and the axis is perfectly straight. At the nanometer-level, this assumption is not realistic.

The new ASME standard recognises that in nanometer-level precision systems, ‘other’ errors that were previously ignored in less accurate systems often become equal to or greater contributors to the 6D repeatability performance. At the nanometer-level, the axis of travel should actually be shown as bending and twisting through three-dimensional space and thus plane visualization becomes meaningless as it will tip, tilt, and twist as the stage moves along the axis. The stage moves in 6D space, therefore neglecting these additional error sources can result in a misrepresentation of actual stage repeatability performance.

Each linear (or angular) direction the stage moves (or rotates) in results in a positional error in that direction. That motion, which must not be neglected when nanometer-precision is desired, will have an associated repeatability of that error motion. Each point on a stage mounting surface will move in 3D space as of a result of this error motion in 6-DOF. It is the point repeatability of an infinite number of points attached to a stage that must be characterized by testing and specification data. Thus, each point repeatability will result in a spherical repeatability range.

Hennessey concludes, “ALIO applauds the new ASME standard officially published and made available a few days ago. In our view, this is a very important step towards True Nano® Positioning, allowing customers the ability to choose the best motion system for their applications based on a common standard rather than believing misleading, single dimensional specifications that vary from supplier to supplier. Because ALIO has already been applying these newly published measurement procedures for over a decade, our customers find themselves in the lucky position of not having to worry about the true performance of their products. ALIO will continue to be at the forefront of innovation and progress in the precision positioning industry. The new standard methods for the performance evaluation of single-axis positioning systems can only be the beginning though. Today’s motion systems are more complex, usually consisting of not just one linear axis, but combining multiple axis to 2, 3, 4 or 6 or more degrees of freedom. ALIO is ready to drive these next steps with the ASME and all other contributors to the ASME B5.64 to further improve the transparency and creditability of the precision motion world.”

(25th July 2023, Arvada, CO, USA) Precision motion control systems play a vital role in ensuring high quality and consistency in micro-electronic assembly and testing, particularly when it comes to accurate and repeatable positioning of test probes. ALIO Industries (an Allient Company) is at the forefront of innovation in this area, and is able to provide motion systems that meet the incredibly exacting requirements that are common-place in such applications.

In micro-electronic assembly, the components are incredibly small and delicate, requiring precise placement and alignment. Precision motion control systems, equipped with advanced servo motors and encoders, enable micro-electronic manufacturers to position test probes with micron-level accuracy, reducing the risk of misalignment and potential damage to the sensitive components. This accuracy is critical for verifying the functionality of each individual component and ensuring that they work flawlessly within the intricate circuitry of electronic devices.

In addition, micro-electronic testing demands a high degree of consistency to detect even the slightest defects or variations in performance. Precision motion control systems allow for repeatable positioning of test probes during testing processes, ensuring that each component is examined under identical conditions.

By minimizing positional errors, these systems enable reliable and consistent data collection, reducing the likelihood of false positives or negatives in the testing results. This level of consistency is essential in producing reliable electronic devices, as any deviation or inconsistency in testing could lead to faulty products and costly recalls.

Bill Hennessey, President of ALIO Industries says, “The scale of the components being manipulated when testing and assembling micro electronic devices is regularly on the order of micrometers requiring reliable positioning in the low two-digit nanometers. At such small scales, even the slightest inaccuracies in positioning can lead to faulty connections, misaligned components, or inaccurate test results. At ALIO, we innovate high precision nanometer-level motion solutions that can overcome the challenges of testing and assembling micro-electronic devices by employing advanced technologies and design principles. Our solutions incorporate the most accurate linear motors on the market and high-resolution encoders to achieve nanometer-level positioning accuracy. Ironless linear motors offer precise and fast motion with outstanding responsive control at high bandwidths, ensuring that even the tiniest adjustments are made accurately. High-resolution encoders provide real-time feedback, allowing for closed-loop control and immediate correction of any positioning deviations.”

ALIO’s solutions also integrate sophisticated control algorithms and error compensation techniques to enhance accuracy further. Advanced control algorithms optimize motion trajectories, ensuring smooth and accurate movements. Error compensation techniques identify and correct systematic errors, such as thermal effects or nonlinearities, which can adversely affect positioning accuracy. By combining these technologies, ALIO’s high precision nanometer-level motion solutions can reliably and consistently address the challenges posed by microelectronic assembly and testing at such minuscule scales.

Hennessey continues, “ALIO’s rotary and linear motion systems provide high precision down to the nanometer level; excellent bi-directional repeatability, high levels of precision and accuracy, even after thousands or millions of cycles; fast response time, quickly responding to changes in position requirements, allowing for efficient and rapid testing and assembly processes; and minimal backlash ensuring that positioning remains accurate and consistent, even when changes in direction are required. As such, our precision motion control systems are indispensable tools in micro-electronic assembly and testing, guaranteeing the utmost accuracy and repeatability in positioning test probes and contributing to the overall quality and reliability of electronic products.

ALIO’s team of experts can be contacted today to discuss your specific testing and assembly requirements.

(19th July 2023, Arvada, CO, USA) ALIO Industries (an Allient Company) is at the forefront of innovation in ultra-precise and repeatable motion control systems, and as such is working to address the demands from manufacturers of increasingly complex and smaller and smaller integrated circuits (IC).

As complexity increases and size decreases, IC manufacturers lean more and more heavily on sophisticated metrology tools to validate the quality of finished products. Challenges especially escalate when looking at high volume manufacturing, where metrology tools are indispensable for ensuring quality control, optimizing processes, improving yield rates, enabling real-time monitoring, and keeping pace with technological advancements. They provide comprehensive inspection, precise measurements, and feedback on critical parameters, enabling manufacturers to detect defects, optimize processes, and maintain consistent quality throughout large-scale production. By investing in advanced metrology tools driven by best-in-class motion systems, manufacturers can maximize yield, reduce scrap rates, and proactively address deviations, ultimately ensuring the delivery of high-quality ICs in a competitive market driven by ever-advancing technology.

Bill Hennessey, President of ALIO Industries says, “Manufacturers of production and metrology equipment for small and complex ICs have unique and demanding requirements for ultra-precise motion control. They need motion control systems that offer sub-micron accuracy for precise positioning of tiny components, ensuring proper alignment and connection. High-speed operations are also crucial for efficient production throughput. Multi-axis control is necessary to enable synchronized movements in X, Y, Z, and rotation for accurate placement. These motion control systems must have a compact footprint, be flexible to adapt to different layouts, and provide long-term stability and reliability. Integration with automation is vital to streamline processes and maximize productivity. By meeting these demands, manufacturers can achieve high-quality IC production with improved yields and performance.”

In the fast-paced world of semiconductor manufacturing, metrology tools are part of the secret sauce that ensures perfection, and as such need to be controlled by bleeding edge motion control systems. They measure and inspect critical dimensions, overlay accuracy, and defects in integrated circuits, leaving no room for errors.

Hennessey continues, “With real-time feedback and control, these sophisticated tools empower manufacturers to make precise adjustments on the fly, boosting yields and slashing defects. It’s a game-changer for precision-driven production, where every measurement counts and perfection is the ultimate prize.”

ALIO Industries excels in creating motion control solutions for demanding metrology applications for a number of reasons. Firstly, ALIO’s expertise lies in delivering sub-micron accuracy and precise positioning required for measuring critical dimensions and overlay accuracy in ICs. Secondly, the company’s motion control systems offer multi-axis control and compact designs, catering to the intricate movements and space limitations of complex metrology systems.

Additionally, ALIO’s solutions provide the necessary stability, reliability, and adaptability to optimize processes, improve yields, and seamlessly integrate with automation in high-volume manufacturing environments. The company’s commitment to innovation and its deep understanding of the specific demands of metrology make them a trusted partner in delivering exceptional motion control solutions for these exacting applications, and it has the ability to customize solutions where required.

Hennessey concludes, “One notable example entailed the development of a semiconductor metrology low-profile XY-theta stage featuring a large open aperture. The design challenge involved an open frame stage with a configuration that hindered the implementation of a centered drive mechanism, thereby impeding the attainment of a symmetrical force distribution along the axis. ALIO successfully addressed this issue by creating a 300mm open center XY Nano Metrology stage. This stage exhibits a remarkable performance, characterized by a 3-Sigma, 6-D assessment encompassing parameters such as linear, straightness, flatness, pitch, yaw, and roll. Furthermore, the stage showcases a bi-directional repeatability within the range of less than +/- 250nm.”

ALIO’s team of dedicated engineers remains on hand to discuss your requirements when optimizing in the semiconductor industry.

ALIO Industries, an Allient company, is a leader in producing high-precision motion control systems with ultra-precise point and path positioning performance that is NIST-traceable. The company’s off-the-shelf and customized motion control solutions are the most precise and repeatable in the world, all backed by the industry’s first 3-year warranty. In this article Bill Hennessey, Founder and President of ALIO Industries gives his views on the ever changing and evolving demand for more and more precise motion control solutions, and discusses his and ALIO’s approach to the creation of technology that stimulates innovation across industry.

Q. Can you provide an overview of ALIO and its core focus as an ultra-precise motion control specialist technology supplier?

BH. From day one ALIO’s focus was to push the nanometer envelop using novel ideas from machining to assembly. Personally, I thought nanometer-level motion control was needed as far back as the JDS Uniphase Corporation (JDSU) days in the 1990s when they were designing and manufacturing a variety of products for optical communications networks. The Dense wavelength-division multiplexing (DWDM) optical transmission technology that took over from the JDSU technologies in the 2000s definitely needed nanometer-level motion control. For industries such as this where precision was so vital, quality was also a must as were motion control solutions that were robust industrial products not just devices to be used in a lab. I used my machine tool and industrial robots background to build quality, precise motion control systems that were fit for high volume manufacturing scenarios. At the same time as we applied for the patent for our novel Piezo Hybrid Hexapod, along came Dense Wavelength-Division Multiplexing (DWDM) optical transmission technology, and this industry suddenly did not need as many devices since a fiber could now carry many different channels.

Q. What factors do you believe have contributed to ALIO’s success in the motion control industry?

BH. We stayed the course and never sacrificed our integrity, focus, or reputation for quality by compromising the exacting precision levels that we pioneered. We have lost many orders over the years by telling customers the truth about what they could expect in terms of precision. Customers ending up with inappropriate or sub-optimal motion control solutions does nothing for the reputation of the entire motion control sector, and with this in mind we continue to put honesty in customer dialogue beyond anything else. From this, creating and providing pragmatic solutions that meet customer expectations can follow.

Q. Could you share some examples of how ALIO’s motion control solutions have delivered significant benefits to customers compared to traditional alternatives?

BH. We provide game changing products that are disruptive due their precision and quality across an array of industries and applications. Unfortunately, due to the strategic nature of the motion control solutions that we provide, we are usually unable to give specific details. However, I can tell you that we have customers that not only restrict us from mentioning them, but who ask (or even offer to pay a premium) for us not to place our name on the motion control systems we have supplied them so they can protect their technological advantage.

Q. What are the key application areas that ALIO is currently focused on in terms of providing ultra-precise motion control solutions?

BH. Metrology has always been an ALIO specialty, with the world’s top metrology companies using out products as their internal reference systems, and some as their OEM system. Ultra-fast laser processing, digital pathology, genome sequencing and a lot of semiconductor processing applications represent our key markets today.

Q. Are there any particular industries or sectors where ALIO’s technology has found the most success and impact?

BH. There are many, but in the area of Digital Pathology we perhaps exhibit our prowess most obviously. To ensure accurate and complete tissue sample analysis, high bi-directional repeatability to target small tissue areas is needed in digital pathology applications. ALIO provides monolithic, low-profile, open-center X, Y, Z electromagnetic driven stages for such applications, promoting high speed, high throughput, and low friction in a small footprint, scan times being reduced allowing better pre-scan images. Digital pathology is all about parallel paths or a serpentine motion to capture all the data points. ALIO is novel in that our straightness is superior to all other motion control options for this application. This promotes the compiling of data in one pass impossible if stages cannot move parallel with less than 2-3 micron variation. This also make for more precise data since it does not need to be calculated by 6 sigma algorithms that are necessary to get a result from poor motion performance.

We also excel in areas like 4K and 8K lens assembly, measuring optics for satellites, laser cutting of gems or sapphire, and genome sequencing all of which require exacting precision and / or the requirement to capture data at record speeds.

Q. How does ALIO stay ahead of emerging trends and technology advancements in the field of ultra-precise motion control?

BH. ALIO began focusing on nanometer-level motion control some 21 years ago, so we never stop thinking of the next generation trends and technologies. At this time, I would say that we are a decade in front of the competition. Without giving away too much, we are always looking at ways to measure and assemble new kinematic motion control solutions with novel materials, and this is an area of particular focus at the moment.

Novel materials can exhibit unique properties such as high stiffness, low thermal expansion, and exceptional dimensional stability, allowing for enhanced precision and accuracy in motion control applications. By incorporating these materials into the design of such systems, it becomes possible to minimize unwanted vibrations, reduce friction, and mitigate the effects of thermal fluctuations, thereby improving overall system performance. Furthermore, the introduction of novel materials can enable the development of miniaturized, lightweight systems with improved reliability, responsiveness, and energy efficiency, opening up new possibilities for advanced motion control in fields such as robotics, microscopy, and precision manufacturing.

Q. What is the company’s strategy for staying innovative and continuously improving its motion control solutions?

BH. Continuous improvement for us at ALIO is like breathing. We are always seeking to improve, and we always ensure we have a team of engineers at the top of their game.

Specifically, we promote continuous improvement by fostering a culture of innovation, collaboration, and feedback. We invest in research and development to explore emerging technologies, novel materials, and advanced algorithms that can enhance the precision, accuracy, and performance of our motion control systems. We actively engage with customers and industry experts to gather feedback and insights, allowing us to identify areas for improvement and address specific customer needs. This feedback-driven approach enables us to iterate on our designs, incorporate user-centric features, and refine our manufacturing processes. Additionally, we prioritize ongoing training and development for members of our team, ensuring they stay updated with the latest advancements and can contribute to the continuous improvement efforts.

By embracing this holistic approach, as an ultra-precise motion control solution provider we can remain at the forefront of innovation, consistently delivering state-of-the-art solutions that exceed customer expectations.

Q. Can you provide insights into any ongoing research and development efforts at ALIO aimed at advancing ultra-precise motion control?

BH. The challenge for ALIO is trying as far as possible to mitigate the costs of materials and software etc… that allows our nanometer-level precision motion control systems to operate in scenarios where environmental conditions in industrial settings are not ideal.

Building ultra-precise motion control systems operating in environmental conditions that include thermal deviations and vibrations poses significant challenges. The presence of thermal fluctuations introduces unpredictable dimensional changes in the system, requiring careful thermal management strategies to minimize their impact on positioning accuracy. Vibrations, whether originating from internal or external sources, can disrupt the delicate motion control mechanisms and degrade overall performance.

Addressing these challenges requires a combination of meticulous mechanical design, sophisticated control algorithms, and the use of specialized materials with low thermal expansion and high stiffness to minimize the effects of thermal deviations and vibrations. Additionally, advanced sensing and feedback systems, such as precision accelerometers and encoders, are necessary to continuously monitor and compensate for any disturbances, enabling the system to maintain the desired nanometer-level precision even in challenging environmental conditions.

Q. What steps does ALIO take to ensure that its customers achieve optimal results and maximize the performance of the motion control systems they purchase?

BH. Every machined part and indeed every assembly gets tested and approved before it leaves our facility. Most suppliers test stages not motion systems. But how can a customer be confident in a motion system that hasn’t been tested as solution. It is effectively nothing other than several individually tested stages stacked together, hoping the performance of individual stages have not been compromised in the process. By testing every motion systems before delivery we ensure it works perfectly on day one at the customer’s facility.

We also have a metrology lab that has few equals, and we have developed over the years our Point Precision® approach to motion metrology that has recently been adopted into ASME B5.64 standard for motion metrology.

All motion systems operate in 3-dimensional space and have errors in 6 degrees of freedom (6-DOF). However, motion systems are often only characterized by performance data of a single or subset of these 6-DOF. This practice leaves several error sources unaccounted for in performance data and specifications. ALIO has contended for over 20 years that repeatability performance for metrology inspection and manufacturing systems must be analyzed and specified using a “point repeatability” method that accounts for 6D spatial errors in order to provide true representation of nanometer-precision performance. The ASME B5.64 standard for motion metrology shows that today standards organisations also see its importance.

Q. What do you believe sets ALIO apart from other motion control technology suppliers in terms of its approach, expertise, or customer-centricity?

BH. Well, quite simply we have been doing this for 21 years, and the mission has always been the same, nanometer-level precision and quality . We always think out of the box, which is reflected in the definition of ALIO…. a new and better way!

We have never built a product without a customer application in mind. Where most build standard products, we have developed our portfolio of motion control solutions based on real world applications.

Q. In your opinion, what are the key qualities or factors that customers should consider when selecting a motion control solutions provider, and how does ALIO excel in those areas?

BH. Never take spec sheets from our competition at face value. Many quote “best-case” precision data, not the precision that can be met day in and day out repeatably.

Also, ask about warranty. If it is one year, then run for the hills. Customer application development can take years, so they need support for a long time to get over the learning curve.

In addition, ask your shortlisted supplier if they can prove they have what it takes to meet or exceed your requirements. Point Precision® in the ASME B5.64 standard is one way to make sure the product meets your need for the application. A reliance on old school planar data can be misleading, and in worst case scenarios can kill off projects due to under-performance.

Finally, look for evidence of a state-of-the-art metrology lab, and also a cleanroom for next-level assembly required by and increasing number of applications across industry.

If all of the above can be answered and demonstrated positively then you can only be at our facilities in Arvada. We look forward to working with you!!

ALIO Industries is proud to announce that it has just introduced an ISO Class 8 cleanroom to its Arvada, CO facilities with ISO Class 5 (US FED STD 209E: Class 100) workstations.

The cleanroom has been commissioned due to a substantial increase in demand for cleanroom manufacturing and handling, and the facility is fully equipped to handle vacuum and cleanroom products and requirements.

Peter Lehner, Director of Sales and Marketing at ALIO says, “Most of the demand for cleanroom manufacturing is driven by customers in the semiconductor, micro-electronics, and medical industries. Our new cleanroom not only enables contamination control, ensuring the production environment has minimal airborne particles that could compromise product quality (critical for industries that demand high levels of cleanliness to prevent defects or failures in motion control devices), but it also maintains process consistency by offering controlled conditions. The cleanroom simplifies adherence to industry expectations, standards and regulations, and also instills customer confidence by showcasing our commitment to quality, precision, and customer satisfaction for which ALIO is renowned.”

The cleanroom is another in a series of significant investments undertaken by ALIO which also includes on-going investment in maintaining and optimizing its metrology lab and equipment, allowing the company to guarantee the unique one-of-a-kind nanometer-level precision attainment for which it is world famous.

Bryan McCloskey, Operations Manager at ALIO says, “The continuous investment into lean manufacturing principles, our new cleanroom, and our growing metrology lab demonstrates our commitment to quality, cleanliness, and precision. Customers can trust our consistent and reliable products, innovative approach, adherence to standards, and long-term partnership potential, making them confident in receiving the highest-quality motion control solutions.”

(June 5th 2023, Arvada, CO, USA) Additive manufacturing (AM) is crucial for manufacturers today because it enables the production of highly complex and customized parts that are difficult or impossible to achieve with traditional manufacturing methods. It offers increased design freedom, faster prototyping, reduced material waste, and the ability to create on-demand, decentralized production networks, all of which contribute to enhanced efficiency and competitiveness in the modern manufacturing landscape. AM has long disrupted the prototyping stage of product development, but recent advances in speed of operation, improved materials, and optimization software, now see AM becoming a disruptive force in production scenarios.